A matsayin tsarin masana'antu na asali tare da tarihin shekaru 6000, fasahar jefar ba wai kawai tana da dogon tarihi ba, amma a lokaci guda ta mamaye sabbin fasahohi, sabbin kayayyaki da sabbin hanyoyin da aka haɓaka a kimiyyar zamani a cikin lokaci. Muna da alhakin ci gaba da wannan masana'antar masana'antu ta asali. Abubuwan da ke gaba sune wasu daga cikin tunaninmu don cigaban ci gaban tsarin simintin yashi a nan gaba.

1 Fasahar kafuwa tana haɓakawa zuwa tanadin makamashi da ceton kayan aiki

A cikin tsarin samar da simintin gyare-gyare, ana amfani da makamashi mai yawa a cikin aikin narkewar karfe. A lokaci guda, buƙatar abubuwan da ake amfani da su a cikin aikin simintin yashi kuma yana da girma. Sabili da haka, yadda za a inganta makamashi da kayan aiki shine babban batu da ke fuskantar tsire-tsire masu yashi. Matakan da aka saba amfani da su sun haɗa da:

1) Dauki ci-gaba na yashi gyare-gyare, core-yin fasaha da kayan aiki. A cikinyashi simintin samar da tsari, Babban matsa lamba, matsa lamba, matsa lamba na allura da kayan bugun iska ya kamata a yi amfani da su gwargwadon yiwuwa. Kuma kamar yadda ya zuwa yanzu don amfani da kai hardening yashi.rasa kumfa, vacuum simintin gyare-gyare da simintin gyare-gyare na musamman (kamarzuba jari, Karfe mold simintin gyare-gyare) da sauran fasaha.

2) Yashi dawo da sake amfani. Lokacin jefa sassan ƙarfe mara ƙarfe, simintin ƙarfe da simintin ƙarfe, bisa ga yanayin zafin yashi, adadin dawo da tsohon yashi da injina zai iya kaiwa 90%. Daga cikin su, haɗuwa da sake yin amfani da yashi da sake farfadowa da rigar shine hanya mafi dacewa da farashi mai tsada.

3) Sake amfani da adhesives. Misali, idan an cire simintin ta hanyar busasshiyar kuma mannen ya kasance a cikin yashi, tsarin da ya dace zai iya sa a sake amfani da mannen, ta yadda za a rage tsadar man.

4) Farfadowar kayan kwalliya da kayan kwalliya.

2 Karancin gurɓata ko ma babu gurɓata

Tushen simintin yashi yana samar da ruwan sha mai yawa, iskar gas da ƙura yayin aikin samarwa. Saboda haka, tushen ba kawai babban gida mai cin makamashi ba ne, amma har ma babban tushen gurɓataccen abu. Musamman a kasar Sin, gurbacewar muhallin da ake samu ya fi sauran kasashe tsanani. Daga cikin su, kura, iska da dattin da ake fitarwa daga tsire-tsire masu yashi sune mafi tsanani. Musamman ma a cikin 'yan shekarun nan, manufofin kiyaye muhalli na kasar Sin sun kara yin tsauri, kuma ya zama tilas a kafa masana'antu da su dauki kwararan matakai don dakile gurbatar yanayi. Don cimma kore da tsaftataccen samar da simintin yashi, yakamata a yi amfani da koren inorganic binders gwargwadon yadda zai yiwu, ko ƙasa da haka ba za a yi amfani da su ba. Daga cikin ayyukan simintin yashi a halin yanzu, ɓataccen simintin kumfa, simintin aikin V da simintin yashi na silicate yashi sun dace da muhalli. Saboda ɓataccen simintin kumfa da tsarin V na amfani da ƙirar yashi bushe wanda baya buƙatar ɗaure, yayin da simintin yashi na sodium silicate yana amfani da abubuwan ɗaure.

3 Mafi girman girma da daidaiton geometric na simintin gyare-gyare

Tare da haɓaka madaidaicin tsari na simintin simintin gyare-gyare, daidaiton gemometical da girma na ɓangaren kafa yana tasowa daga kusa da sifar net ɗin da ke ƙulla sifar hanyar sadarwa, wato kusan babu wani gefe. Bambanci tsakanin simintin simintin gyare-gyare da sassan da ake buƙata yana ƙara ƙarami da ƙarami. Bayan an yi wasu guraben, sun matso ko sun kai siffar ƙarshe da girman sassan, kuma ana iya haɗa su kai tsaye bayan an niƙa.

4 Kasa ko babu lahani

Wani alamar simintin ƙeƙasasshe da matakin matakin sassa shine lamba, girma da lalacewar lahani. Saboda aikin zafi da aikin simintin ƙarfe suna da sarƙaƙƙiya kuma abubuwa da yawa suna tasiri, lahani na simintin yana da wahala a guje wa. Koyaya, kaɗan ko babu lahani shine yanayin gaba. Akwai matakai masu tasiri da yawa:

1) Karɓar fasahar ci-gaba don haɓaka ɗimbin tsarin gami da aza harsashin samun simintin sauti.

2) Yi amfani da software na simintin simintin simintin gyare-gyare don kwaikwayi ainihin aikin simintin a matakin ƙira a gaba. Dangane da sakamakon kwaikwayo, an inganta ƙirar tsari don gane nasarar gyare-gyaren lokaci ɗaya da gwajin ƙira.

3) Ƙarfafa tsarin kulawa da aiwatar da ayyuka daidai da ƙayyadaddun umarnin aiki.

4) Ƙarfafa gwaji mara lalacewa a cikin tsarin samarwa, gano sassan da ba daidai ba a cikin lokaci kuma ɗaukar matakan gyarawa da ingantawa.

5) Ƙayyade ƙima mai mahimmanci ta hanyar bincike da kimantawa na aminci da amincin sassan.

5 Samar da simintin gyare-gyare mai sauƙi.

A wajen kera motocin fasinja.manyan motoci, da sauran kayan aikin sufuri, yadda za a rage nauyin sassa yayin da tabbatar da ƙarfin sassa shine yanayin da ke kara fitowa fili. Akwai manyan abubuwa guda biyu don cimma raguwar nauyi. Ɗayan shine yin amfani da ɗanyen haske, ɗayan kuma shine don rage nauyin sassa daga tsarin tsarin sassan. Dominyashi simintin gyaran kafasuna da sassauƙa sosai a ƙirar tsari, kuma akwai kuma da yawa na gargajiya da sabbin kayan ƙarfe da za a zaɓa daga, simintin yashi na iya taka rawa sosai wajen samar da nauyi.

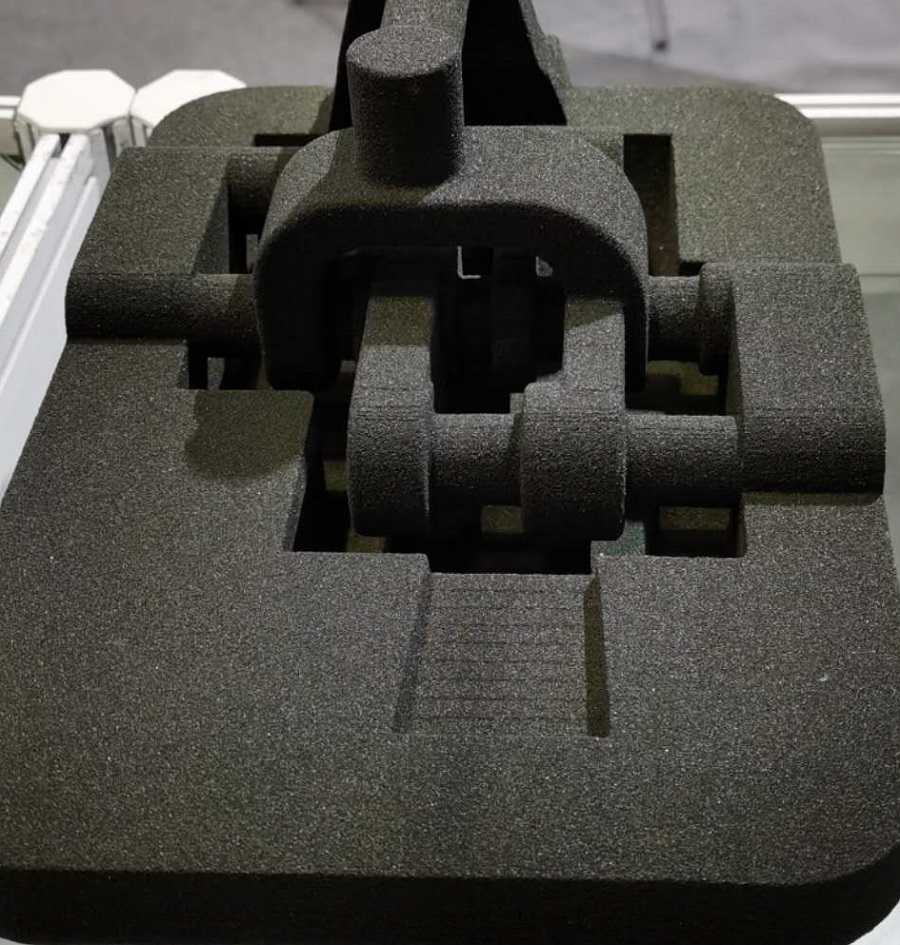

6 Aikace-aikacen sabbin fasahohi kamar bugu na 3D a cikin ƙirar ƙira

Tare da haɓakawa da balaga na fasahar bugu na 3D, ana kuma ƙara yin amfani da shi sosai a filin wasan. Idan aka kwatanta da ci gaban gyare-gyare na gargajiya, fasahar bugu na 3D na iya samar da gyare-gyaren da ake buƙata da sauri a ƙananan farashi. A matsayin fasaha mai saurin samfuri, bugu na 3D na iya ba da cikakkiyar wasa ga fa'idodinsa a cikin samar da samfurin gwaji da ƙananan matakan simintin gyare-gyare.

Lokacin aikawa: Dec-25-2020