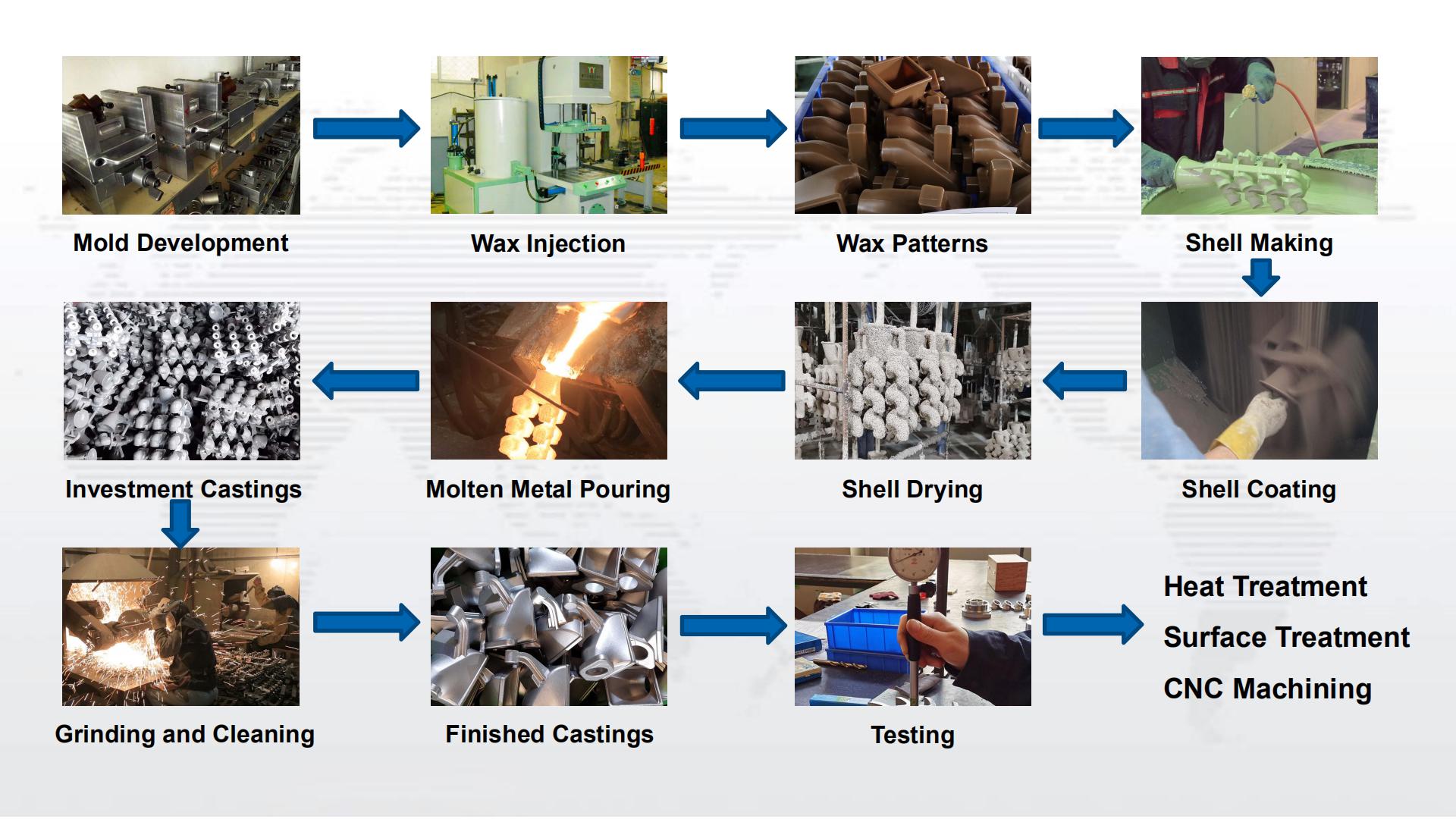

Yin simintin saka hannun jari, ko daidaitaccen simintin gyaran fuska da wani suna, yana buƙatar saitin kayan aiki na musamman kamar injin alluran kakin zuma, injin dewaxing, makera tanderu, tanderun lantarki da sauran injunan sarrafa bayanai kamar spectrometer, injin fashewar fashewa, tumbling da layin tsaftace acid. ...da sauransu. A RMC Foundry, muna amfani da sabbin fasahohi na ci gaba da na'urori masu yanke hukunci a matakai daban-daban na tsarin simintin saka hannun jari. Ƙirar kayan aiki, allurar ƙirar kakin zuma, taron ƙirar kakin zuma, yin harsashi, zubowa, magani mai zafi, da gwaji duk ana yin su ta amfani da ingantattun injuna, waɗanda ƙwararrun ƙungiyar ƙwararrunmu ke sarrafa su.

Kayan alluran kakin zuma

RMCZuba Jari Cemin Foundryyana amfani da injin allura na kakin zuma na atomatik don yin ƙirar kakin zuma da injin dewaxing don sharewa ba tare da nakasar harsashi ba. Injin allurar mu na kakin zuma yana ƙara inganci akan yin ƙirar kakin zuma. Zai iya dumama ƙaƙƙarfan kakin zuma kuma ya kiyaye zafin da ake so yadda ya kamata. Bugu da ƙari, yana iya ciyar da kakin zuma ta atomatik tare da taimakon tsarin matsa lamba. Injin alluran kakin mu na atomatik yana ba mu damar samun mafi girman yawan simintin gyare-gyare da rage lokutan gubar don ayyukan samar da girma. Mahimmancinmu kan sarrafa kansa yana taimakawa rage haɗarin sarrafa lalacewa. Godiya ga wannan fasaha ta injin allurar kakin zuma ta atomatik, za'a iya ceton farashin ma'aikata sosai a lokacintsarin simintin zuba jari.

Wutar Lantarki

Tare da ingantattun tanda mai tsabta da tsabta a cikin tsarin simintin saka hannun jari, an inganta yanayin aikin mu da yawa fiye da da da sauran wuraren da aka kafa.

Spectrometer don Yin Nazari Abubuwan Haɗaɗɗen Sinadarai

Spectrometer yana da matukar mahimmanci ga kowagami karfe zuba jari simintin gyaran kafa. Ana amfani da shi don nazarin abun da ke ciki ko sinadarai kafin zuba narkakkar karfe. Wannan bincike zai iya tabbatar da cewa sinadarin narkakkar karfen da ke cikin kowace tanderu yayi daidai da lambobin da ake buƙata.

Layin Maganin Zafi

Layin maganin zafi ɗinmu ya ƙunshi kayan aiki daga mai ba da maganin tanderu na dogon lokaci. Mu CNC zafi magani line iya yin mahara ayyuka kamar kwandishan, bayani, carbon maidowa, carbonitriding, da kuma tempering na carbon karfe, bakin karfe, high gami karfe da kuma low gami karfe. Layin mu na maganin zafi yana gudanar da sa'o'i 24 a rana tare da yin lodin hannu kawai da saukewa da ake buƙata idan ya cancanta.

CNC Machining Equipment

Madaidaicin simintin gyare-gyaren ƙarfe koyaushe yana haɗa da aikin injin CNC na ƙarshe. RMC karfe zuba jari simintin gyaran kafa kafa sau ɗaya ya kasance adaidai machining factorytare da cikakken machining wurare kamar CNC juya inji, m lathers, CNC milling inji, nika inji, hakowa da tapping inji, honing inji, sauki tebur juya inji da CNC machining cibiyoyin.

Binciken Laboratory da Gwaji

Dukkanin samfuran simintin gyare-gyare ana duba su sosai daidai da hanyoyin sarrafa ingancin ciki don tabbatar da bin ƙayyadaddun abokin ciniki da masana'antu da ƙa'idodi. Bincikenmu ya ƙunshi na'urori masu daidaitawa guda uku (CMM) waɗanda ke iya tabbatar da girma. Hakanan muna amfani da tsauraran PPAP da hanyoyin tabbatar da kwarara don tabbatar da ingancin duk kayan yayin aikin masana'anta. Ana ci gaba da aiwatar da matakan bincike na ƙarshe tare da tsarin gwajin X-ray na atomatik na tashoshin mu da yawa. Wannan yana tabbatar da cewa duk samfuran da ke barin kayan aikinmu ba su da lahani na ciki kamar giɓi, tsagewa, ramuka, ko haɗawa wanda zai iya yin lahani ga amincin tsarin ɓangaren.

Lokacin aikawa: Fabrairu-05-2021