Maganin zafi na simintin ƙarfe yana dogara ne akan zane-zane na Fe-Fe3C don sarrafa ƙananan simintin ƙarfe don cimma aikin da ake buƙata. Maganin zafi yana ɗaya daga cikin mahimman matakai a cikin samar da simintin ƙarfe. Ingancin da tasirin maganin zafi suna da alaƙa kai tsaye da aikin ƙarshe na simintin ƙarfe.

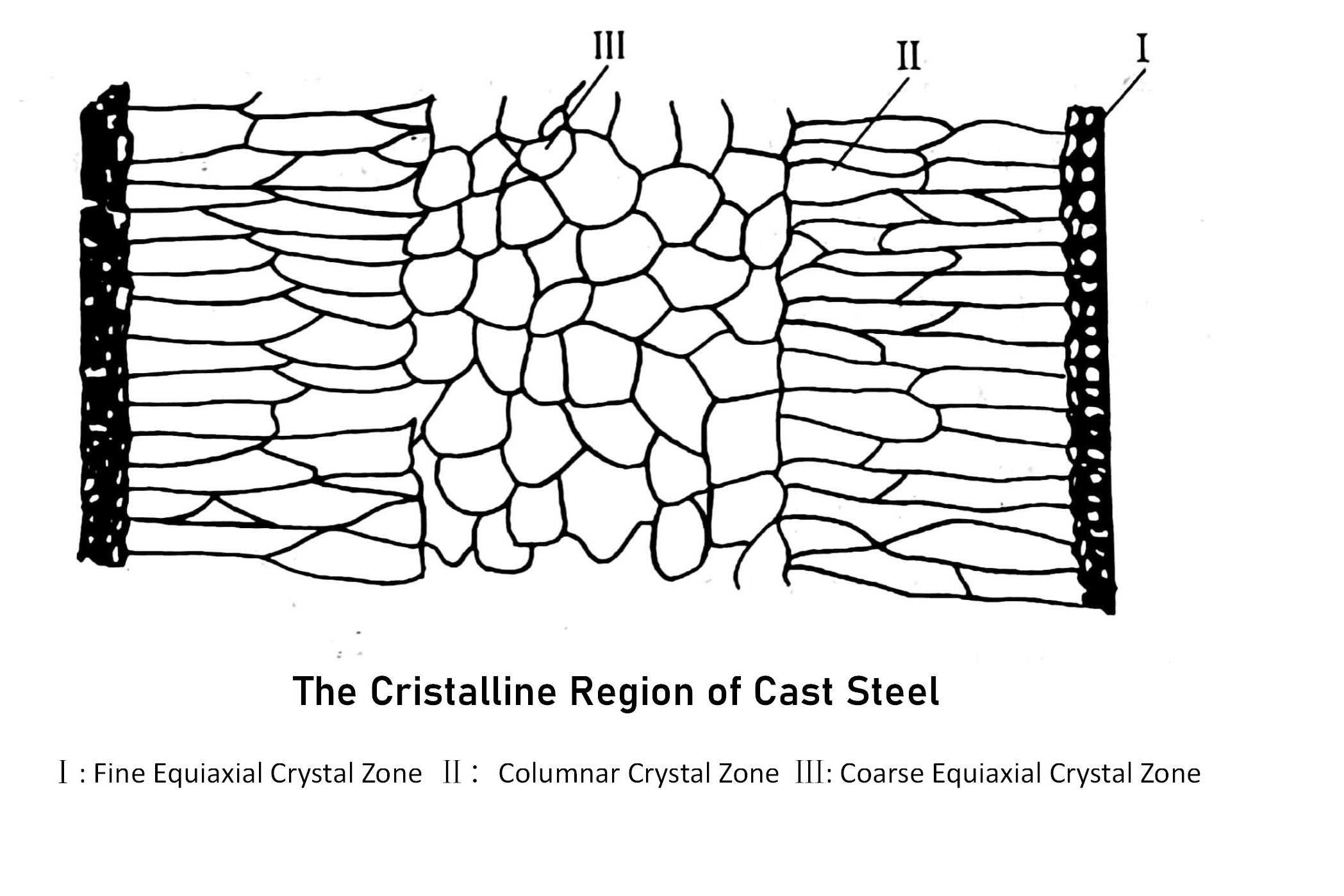

Tsarin simintin simintin ƙarfe na simintin ƙarfe ya dogara da tsarin sinadarai da tsarin ƙarfafawa. Gabaɗaya, akwai rarrabuwar kawuna na dendrite, tsarin da bai dace ba da ƙwaya mara nauyi. Don haka, simintin ƙarfe gabaɗaya yana buƙatar kulawa da zafi don kawar da ko rage tasirin matsalolin da ke sama, ta yadda za a inganta kayan aikin simintin ƙarfe. Bugu da ƙari, saboda bambancin tsari da kaurin bango na simintin ƙarfe, sassa daban-daban na simintin guda ɗaya suna da nau'ikan ƙungiyoyi daban-daban kuma suna haifar da raguwar damuwa na ciki. Don haka, simintin gyare-gyaren ƙarfe (musamman simintin ƙarfe) gabaɗaya ya kamata a isar da shi a yanayin yanayin zafi.

1. Halayen Maganin Zafin Karfe

1) A cikin tsarin simintin simintin gyare-gyare na simintin ƙarfe, sau da yawa ana samun ƙananan dendrites da rarrabuwa. A lokacin maganin zafi, lokacin dumama ya kamata ya zama dan kadan sama da na sassa na ƙarfe na ƙirƙira na wannan abun da ke ciki. A lokaci guda, lokacin riƙewa na haɓaka yana buƙatar tsawaita yadda ya kamata.

2) Saboda tsananin rarrabuwar kawuna na tsarin simintin simintin gyare-gyare na wasu simintin gyare-gyaren ƙarfe, don kawar da tasirin sa akan kaddarorin ƙarshe na simintin gyare-gyare, yakamata a ɗauki matakan daidaitawa yayin jiyya na zafi.

3) Don simintin ƙarfe tare da sifofi masu rikitarwa da manyan bambance-bambancen kauri na bango, dole ne a yi la'akari da tasirin giciye da abubuwan damuwa yayin jiyya na zafi.

4) Lokacin da ake yin maganin zafi akan simintin ƙarfe, dole ne ya zama mai ma'ana dangane da sifofin tsarin sa kuma yayi ƙoƙarin gujewa nakasar simintin.

2. Muhimman Abubuwan Da Yake Dauka Na Maganin Zafin Karfe

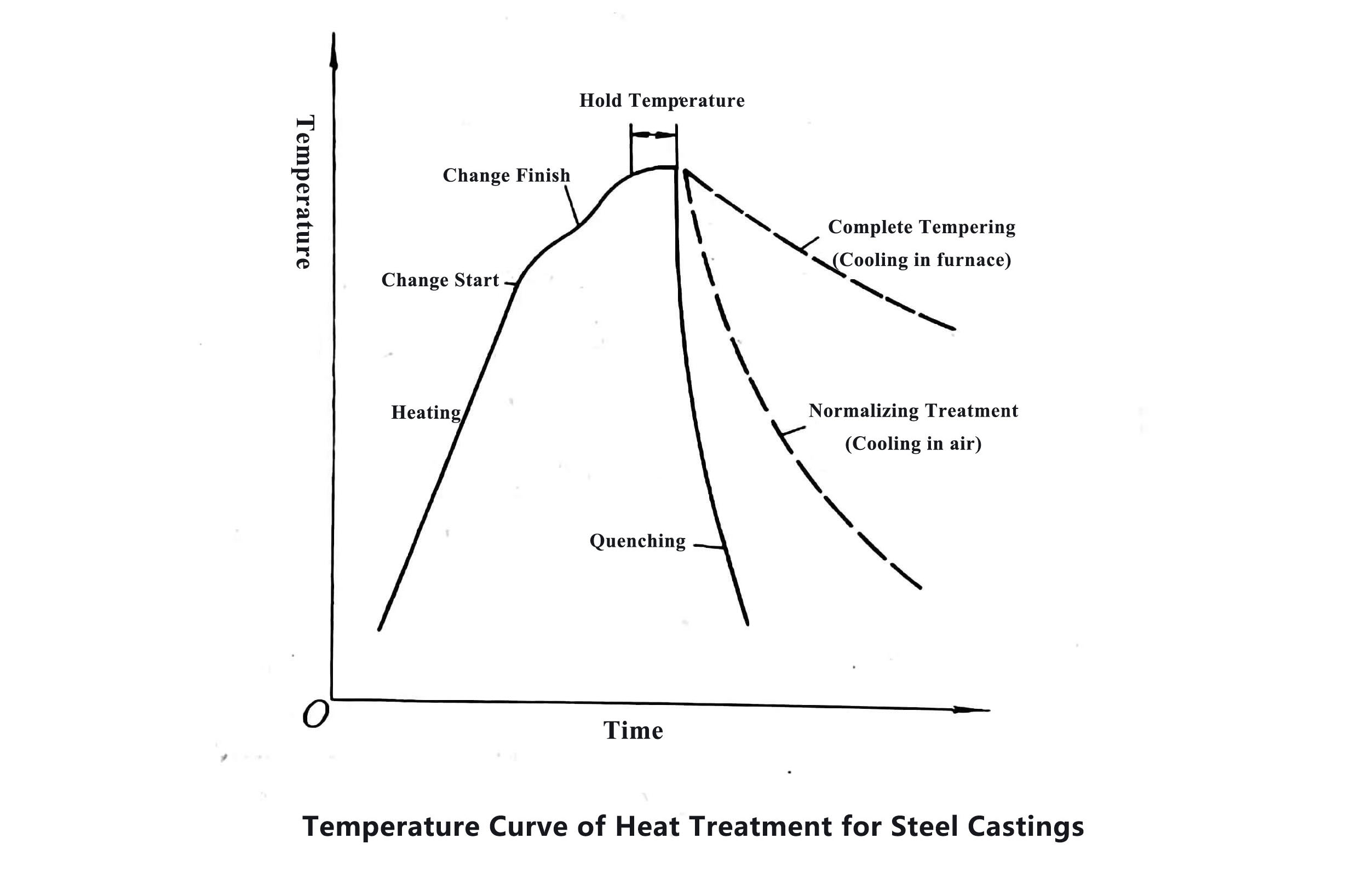

Maganin zafi na simintin ƙarfe ya ƙunshi matakai uku: dumama, adana zafi, da sanyaya. Ƙayyadaddun sigogin tsari ya kamata a dogara ne akan manufar tabbatar da ingancin samfur da kuma adana farashi.

1) dumama

Dumama shine tsarin da ya fi amfani da makamashi a cikin tsarin maganin zafi. Babban ma'auni na fasaha na tsarin dumama shine don zaɓar hanyar dumama mai dacewa, saurin dumama da hanyar caji.

(1) Hanyar dumama. Hanyoyin dumama na simintin ƙarfe musamman sun haɗa da dumama mai haske, dumama wankan gishiri da dumama shigar. Hanyar zaɓi na hanyar dumama yana da sauri da daidaituwa, sauƙin sarrafawa, babban inganci da ƙarancin farashi. Lokacin dumama, ginin ginin gabaɗaya yana la'akari da girman tsarin, abun da ke tattare da sinadarai, tsarin kula da zafi da buƙatun ingancin simintin.

(2) Gudun dumama. Don simintin gyare-gyare na ƙarfe na gaba ɗaya, gudun dumama bazai iyakance ba, kuma ana amfani da iyakar ƙarfin tanderu don dumama. Yin amfani da cajin tanderu mai zafi na iya rage lokacin dumama da sake zagayowar samarwa. A gaskiya ma, a ƙarƙashin yanayin saurin dumama, babu wani yanayin zafi a fili tsakanin farfajiyar simintin gyaran kafa da ainihin. Jinkirin dumama zai haifar da raguwar haɓakar samarwa, ƙara yawan amfani da makamashi, da kuma oxidation mai tsanani da decarburization a saman simintin. Koyaya, don wasu simintin gyare-gyare tare da sifofi da sifofi masu rikitarwa, manyan kaurin bango, da matsananciyar zafi yayin aikin dumama, yakamata a sarrafa saurin dumama. Gabaɗaya, ana iya amfani da ƙananan zafin jiki da jinkirin dumama (kasa da 600 ° C) ko zama a ƙananan zafin jiki ko matsakaici, sa'an nan kuma za'a iya amfani da saurin dumama a wurare masu zafi.

(3) Hanyar lodawa. Ka'idar cewa ya kamata a sanya simintin ƙarfe a cikin tanderu shine don yin cikakken amfani da ingantaccen sarari, tabbatar da dumama iri ɗaya da sanya simintin don lalata.

2) Insulation

Ya kamata a zaɓi zafin riƙon don inganta simintin ƙarfe bisa ga sinadari na simintin ƙarfe da abubuwan da ake buƙata. Matsakaicin zafin jiki gabaɗaya yana ɗan girma (kimanin 20 ° C) fiye da ƙirƙira sassan ƙarfe na abun da ke ciki. Don simintin ƙarfe na eutectoid, ya kamata a tabbatar da cewa za a iya haɗa carbides cikin sauri cikin austenite, kuma austenite na iya kula da hatsi masu kyau.

Ya kamata a yi la'akari da abubuwa biyu don lokacin adana zafi na simintin ƙarfe: abu na farko shine don sanya yanayin zafin jiki na simintin gyare-gyare da kuma ainihin kayan aiki, kuma abu na biyu shine tabbatar da daidaituwar tsarin. Sabili da haka, lokacin riƙewa ya dogara ne akan yanayin zafi na simintin gyare-gyare, kaurin bangon sashin da abubuwan gami. Gabaɗaya magana, simintin gyare-gyaren ƙarfe na gami yana buƙatar ɗaukar lokaci mai tsawo fiye da simintin ƙarfe na carbon. Kaurin bangon simintin gyare-gyare yawanci shine babban tushe don ƙididdige lokacin riƙewa. Don riƙe lokacin jiyya na zafin jiki da jiyya na tsufa, abubuwa kamar manufar magani mai zafi, riƙe zafin jiki da ƙimar rarraba abubuwa yakamata a yi la'akari da su.

3) Sanyi

Za a iya sanyaya simintin ƙarfe na ƙarfe a cikin sauri daban-daban bayan adana zafi, don kammala canjin ƙarfe, samun tsarin ƙarfe da ake buƙata da cimma ƙayyadaddun alamun aiki. Gabaɗaya magana, haɓaka ƙimar sanyaya na iya taimakawa don samun tsari mai kyau da kuma tace hatsi, ta haka inganta kayan aikin simintin. Koyaya, idan adadin sanyaya ya yi sauri, yana da sauƙi don haifar da damuwa mai girma a cikin simintin gyare-gyare. Wannan na iya haifar da nakasu ko fashewar simintin gyare-gyare tare da hadaddun sifofi.

Matsakaicin sanyaya don kula da zafi na simintin ƙarfe gabaɗaya ya haɗa da iska, mai, ruwa, ruwan gishiri da narkakken gishiri.

3. Hanyar Maganin Zafin Karfe

Dangane da hanyoyin dumama daban-daban, riƙe lokaci da yanayin sanyaya, hanyoyin magance zafi na simintin ƙarfe galibi sun haɗa da annealing, daidaitawa, quenching, tempering, maganin warwarewa, taurin hazo, maganin rage damuwa da maganin cirewar hydrogen.

1) Annealing.

Annealing shine dumama karfe wanda tsarinsa ya karkata daga yanayin ma'auni zuwa wani zafin jiki wanda tsari ya kayyade, sannan a hankali sanyaya shi bayan adana zafi (yawanci sanyaya tare da tanda ko binne a cikin lemun tsami) don samun tsarin kula da zafi kusa da daidaitattun yanayin tsarin. Dangane da abun da ke ciki na karfe da maƙasudi da buƙatun ɓacin rai, ana iya raba ɓacin rai zuwa cikakkiyar ɓarna, isothermal annealing, spheroidizing annealing, recrystallization annealing, damuwa da damuwa da sauransu.

(1) Cikakkiyar Annealing. Gabaɗayan tsarin da ake aiwatar da cikakken shafewa shine: dumama simintin ƙarfe zuwa 20 ° C-30 ° C sama da Ac3, riƙe shi na ɗan lokaci, ta yadda tsarin da ke cikin ƙarfe ya canza gaba ɗaya zuwa austenite, sannan a hankali sanyaya (yawanci yawanci). sanyaya tare da tanderun) a 500 ℃- 600 ℃, kuma a karshe sanyaya a cikin iska. Abin da ake kira cikakke yana nufin cewa an samu cikakken tsarin austenite lokacin da zafi.

Manufar cikakken annealing yafi hada da: na farko shi ne don inganta m da m tsarin lalacewa ta hanyar zafi aiki; na biyu shi ne don rage taurin carbon karfe da gami karfe simintin gyaran kafa sama da matsakaici carbon, game da shi inganta su yankan yi (a general, Lokacin da taurin na workpiece ne tsakanin 170 HBW-230 HBW, yana da sauki yanke. Lokacin da taurin). yana da girma ko ƙasa da wannan kewayon, zai sa yanke wuya); na uku shine kawar da damuwa na ciki na simintin karfe.

Kewayon amfani na cikakken annealing. Cikakken annealing yafi dacewa da simintin ƙarfe na carbon da gami da simintin ƙarfe tare da abun da ke ciki na hypoeutectoid tare da abun ciki na carbon daga 0.25% zuwa 0.77%. Karfe na Hypereutectoid bai kamata ya zama cikakke ba, saboda lokacin da ƙarfe na hypereutectoid ya kasance mai zafi zuwa sama da Accm kuma a hankali sanyaya, siminti na biyu zai yi hazo tare da iyakokin hatsi na Austenite a cikin siffar hanyar sadarwa, wanda ya sa ƙarfin, filastik da tasiri taurin karfe yana da mahimmanci. raguwa.

(2) Ciwon Issothermal. Isothermal annealing yana nufin dumama simintin ƙarfe zuwa 20 ° C - 30 ° C sama da Ac3 (ko Ac1), bayan riƙewa na ɗan lokaci, da sauri sanyaya zuwa ga kololuwar zafin jiki na subcooled austenite isothermal canji kwana, sa'an nan kuma riƙe na wani lokaci na lokaci (Yankin canjin Pearlite). Bayan an canza austenite zuwa pearlite, yana kwantar da hankali a hankali.

(3) Spheroidizing Annealing. Spheroidizing annealing shine don dumama simintin ƙarfe zuwa zafin jiki sama da Ac1, sannan bayan dogon lokaci na adana zafi, siminti na biyu a cikin ƙarfe ba tare da bata lokaci ba ya canza zuwa siminti granular (ko mai siffar zobe), sannan a sannu a hankali Maganin zafi. tsari don sanyaya zuwa zafin jiki.

Manufar spheroidizing annealing ya haɗa da: rage taurin; yin tsarin metallographic uniform; inganta yankan yi da shirya don quenching.

Spheroidizing annealing ne yafi zartar da eutectoid karafa da hypereutectoid karafa (carbon abun ciki fiye da 0.77%) kamar carbon kayan aiki karfe, gami spring karfe, mirgina hali karfe da gami kayan aiki karfe.

(4) Taimakon damuwa da damuwa da sake sakewa. Ana kuma kiran kawar da damuwa da rage zafin jiki. Wani tsari ne wanda ake dumama simintin ƙarfe zuwa ƙasa da zafin jiki na Ac1 (400 ° C - 500 ° C), sannan a ajiye shi na ɗan lokaci, sannan a sanyaya a hankali zuwa ɗaki. Manufar kawar da damuwa shine kawar da damuwa na ciki na simintin gyaran kafa. Tsarin metallographic na karfe ba zai canza ba yayin aikin kawar da damuwa. Ana amfani da recrystallization annealing galibi don kawar da gurɓataccen tsarin da ke haifar da nakasar sanyi da kuma kawar da taurin aiki. Zazzabi na dumama don sake sakewa shine 150 ° C - 250 ° C sama da zazzabi recrystallization. Recrystallization annealing iya sake samar da elongated crystal hatsi a cikin uniform equiaxed lu'ulu'u bayan sanyi nakasawa, game da shi kawar da sakamakon taurin aiki.

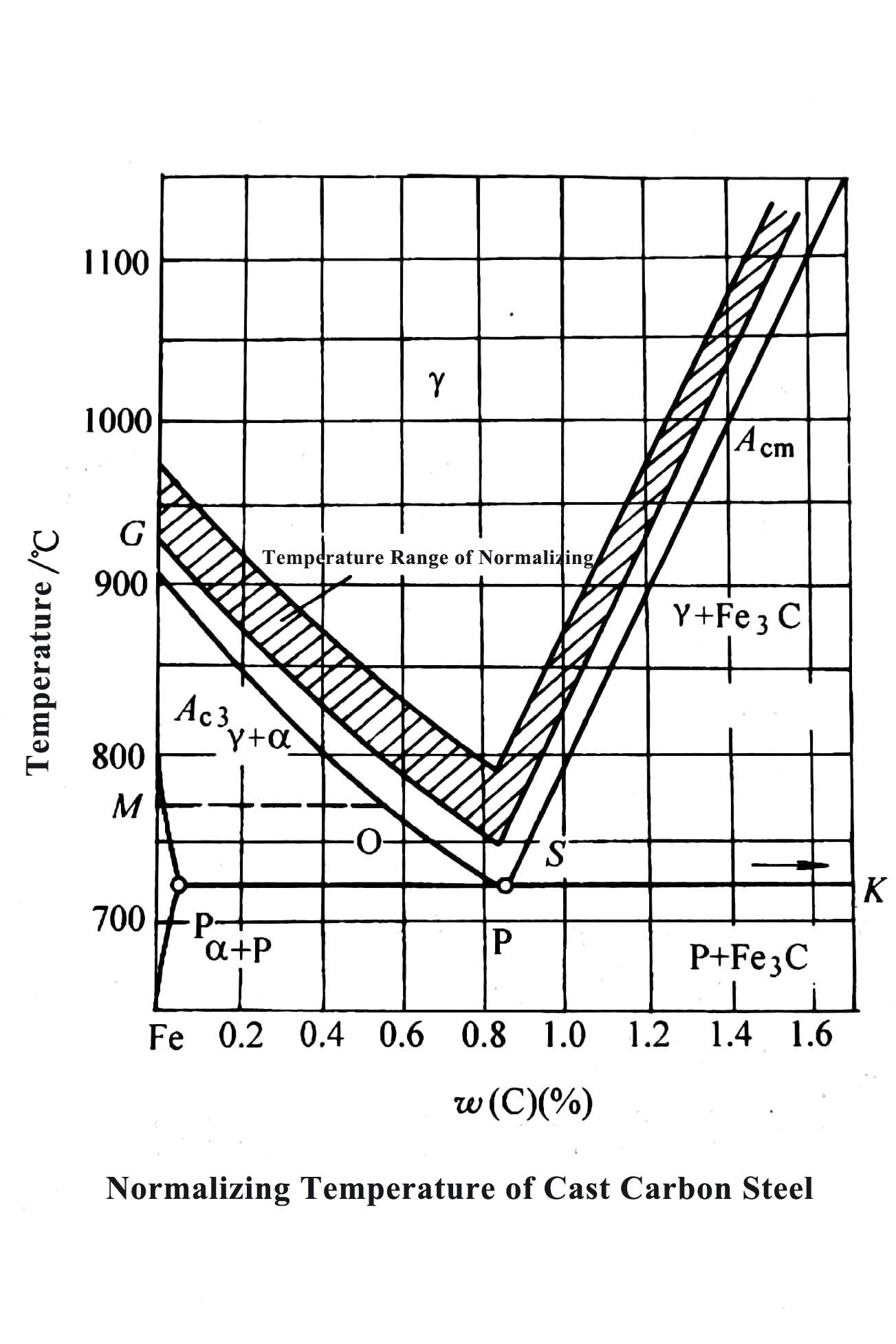

2) daidaitawa

Normalizing wani magani ne na zafi wanda aka yi zafi da karfe zuwa 30 ° C - 50 ° C sama da Ac3 (hypoeutectoid karfe) da Acm (karfe na hypereutectoid), kuma bayan wani lokaci na adana zafi, ana sanyaya shi zuwa zafin jiki a cikin iska ko a ciki. iska ta tilastawa. hanya. Normalizing yana da saurin sanyaya fiye da annealing, don haka tsarin da aka daidaita yana da kyau fiye da tsarin annealed, kuma ƙarfinsa da taurinsa ma sun fi na tsarin da aka rufe. Saboda gajeriyar zagayowar samarwa da babban amfani da kayan aiki na al'ada, ana amfani da al'ada sosai a cikin simintin ƙarfe daban-daban.

Manufar daidaita al'ada ya kasu kashi uku masu zuwa:

(1) daidaitawa azaman maganin zafi na ƙarshe

Don simintin gyare-gyaren ƙarfe tare da ƙananan buƙatun ƙarfi, ana iya amfani da daidaitawa azaman maganin zafi na ƙarshe. Normalizing zai iya tsaftace hatsi, daidaita tsarin, rage abun ciki na ferrite a cikin ƙarfe na hypoeutectoid, ƙarawa da kuma tsaftace abun ciki na pearlite, don haka inganta ƙarfin, taurin da taurin karfe.

(2) daidaitawa azaman maganin zafin jiki

Don simintin gyare-gyaren ƙarfe tare da manyan sassan, daidaitawa kafin quenching ko quenching da tempering (quenching da matsanancin zafin jiki) na iya kawar da tsarin Widmanstatten da tsarin banded, da samun tsari mai kyau da daidaituwa. Don ciminti na cibiyar sadarwa da ke cikin ƙarfe na carbon da kayan aiki na kayan aiki tare da abun ciki na carbon fiye da 0.77%, daidaitawa zai iya rage abun ciki na cementite na biyu kuma ya hana shi ƙirƙirar ci gaba da ci gaba, shirya ƙungiyar don spheroidizing annealing.

(3) Inganta aikin yankan

Normalizing iya inganta yankan yi na low carbon karfe. Taurin ƙananan simintin ƙarfe na carbon ya yi ƙasa da ƙasa bayan annashuwa, kuma yana da sauƙin mannewa wuka yayin yankan, yana haifar da wuce gona da iri. Ta hanyar daidaita yanayin zafi, za a iya ƙara taurin ƙananan simintin ƙarfe na carbon zuwa 140 HBW - 190 HBW, wanda ke kusa da mafi kyawun yanke taurin, don haka inganta aikin yankewa.

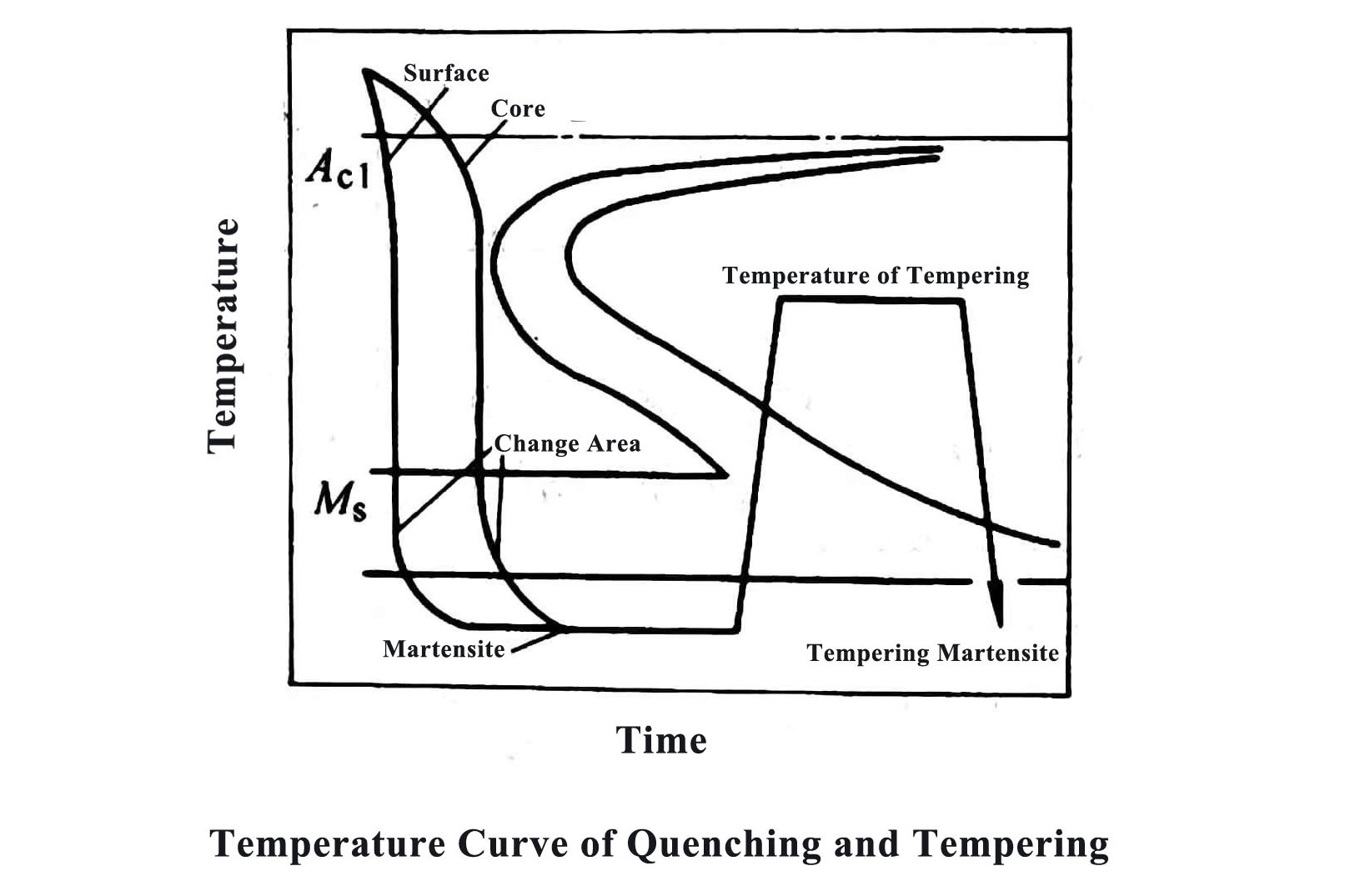

3) Quenching

Quenching wani tsari ne na maganin zafi wanda ake dumama simintin ƙarfe zuwa zafin jiki sama da Ac3 ko Ac1, sannan a yi saurin sanyaya bayan riƙe shi na ɗan lokaci don samun cikakken tsarin martensitic. Ya kamata a huce simintin ƙarfe na ƙarfe a cikin lokaci bayan mafi zafi don kawar da damuwa mai kashewa da samun cikakkun kayan aikin injin da ake buƙata.

(1) Rage zafin jiki

The quenching dumama zafin jiki na hypoeutectoid karfe ne 30 ℃-50 ℃ sama Ac3; da quenching dumama zafin jiki na eutectoid karfe da hypereutectoid karfe ne 30 ℃-50 ℃ sama Ac1. Hypoeutectoid carbon karfe ana zafi da zafi a sama da aka ambata a sama quenching zafin jiki domin a sami kyau grained austenite, da kuma m martensite tsarin za a iya samu bayan quenching. The eutectoid karfe da hypereutectoid karfe an spheroidized da annealed kafin quenching da dumama, don haka bayan dumama zuwa 30 ℃-50 ℃ sama Ac1 da incomplete austenitized, da tsarin ne austenite da partially undissolved lafiya-grained infiltration Carbon jiki barbashi. Bayan quenching, austenite yana canzawa zuwa martensite, kuma ana riƙe barbashi siminti da ba a narkar da su ba. Saboda tsananin taurin siminti, ba wai kawai baya rage taurin karfe ba, har ma yana inganta juriyar sa. Tsarin ƙarewa na yau da kullun na ƙarfe na hypereutectoid yana da kyau maras kyau, kuma siminti mai kyau mai kyau da ƙaramin adadin austenite da aka riƙe ana rarraba su daidai akan matrix. Wannan tsarin yana da ƙarfi mai ƙarfi da juriya, amma kuma yana da ƙayyadaddun ƙarfi.

(2) Matsakaicin sanyaya don kashe tsarin maganin zafi

Manufar quenching shine don samun cikakken martensite. Sabili da haka, ƙimar sanyaya na simintin ƙarfe yayin kashewa dole ne ya fi mahimmancin sanyaya na simintin ƙarfe, in ba haka ba ba za a iya samun tsarin martensite da kaddarorin da suka dace ba. Koyaya, yawan sanyaya da yawa zai iya haifar da lalacewa ko fashewar simintin gyaran kafa. Domin biyan buƙatun da ke sama a lokaci guda, ya kamata a zaɓi matsakaicin sanyaya mai dacewa bisa ga kayan aikin simintin, ko kuma a ɗauki hanyar sanyaya da aka tsara. A cikin kewayon zazzabi na 650 ℃-400 ℃, da isothermal canji kudi na supercooled austenite na karfe ne mafi girma. Don haka, lokacin da simintin ya ƙare, ya kamata a tabbatar da saurin sanyaya a cikin wannan kewayon zafin jiki. A ƙasa ma'anar Ms, ƙimar sanyaya yakamata ya kasance a hankali don hana nakasawa ko fashewa. Matsakaicin Quenching yawanci yana ɗaukar ruwa, maganin ruwa ko mai. A cikin quenching ko austempering, kafofin watsa labarai da aka saba amfani da su sun haɗa da mai zafi, narkakken ƙarfe, narkakken gishiri ko narkakken alkali.

A sanyaya damar ruwa a cikin high zafin jiki yankin na 650 ℃-550 ℃ ne karfi, da kuma sanyaya damar ruwa a cikin low zafin jiki yankin na 300 ℃-200 ℃ ne karfi. Ruwa ya fi dacewa don kashewa da sanyaya simintin ƙarfe na carbon karfe tare da siffofi masu sauƙi da manyan sassan giciye. Lokacin da ake amfani da shi don kashewa da sanyaya, yawan zafin jiki na ruwa bai wuce 30 ° C ba. Sabili da haka, ana ɗauka gabaɗaya don ƙarfafa zagayawa na ruwa don kiyaye zafin ruwa a cikin kewayon da ya dace. Bugu da ƙari, dumama gishiri (NaCl) ko alkali (NaOH) a cikin ruwa zai ƙara ƙarfin sanyi na maganin.

Babban amfani da man a matsayin mai sanyaya matsakaici shi ne cewa sanyaya kudi a cikin ƙananan zafin jiki na 300 ℃-200 ℃ ne da yawa m fiye da na ruwa, wanda zai iya ƙwarai rage ciki danniya na quenched workpiece da kuma rage yiwuwar nakasawa. da tsagewar simintin gyaran kafa. A lokaci guda, da sanyaya damar man fetur a cikin babban zafin jiki kewayon 650 ℃-550 ℃ ne in mun gwada da low, wanda kuma shi ne babban hasara na mai a matsayin quenching matsakaici. The zafin jiki na quenching man ne kullum sarrafawa a 60 ℃-80 ℃. An fi amfani da man fetur don kashe simintin ƙarfe na gami da sifofi masu rikitarwa da kuma kashe simintin ƙarfe na carbon tare da ƙananan sassan giciye da sifofi masu rikitarwa.

Bugu da kari, ana kuma amfani da narkakkar gishiri a matsayin wurin kashe wuta, wanda ya zama wankan gishiri a wannan lokaci. Gishiri mai wanka yana da babban wurin tafasa kuma ƙarfin sanyaya yana tsakanin ruwa da mai. Ana amfani da wanka na gishiri sau da yawa don austempering da matakin quenching, da kuma kula da simintin gyaran kafa tare da sifofi masu rikitarwa, ƙananan girma da ƙaƙƙarfan buƙatun nakasa.

4) Haushi

Tempering yana nufin tsarin kula da zafi wanda aka kashe ko daidaita simintin ƙarfe na ƙarfe zuwa zaɓaɓɓen zafin jiki ƙasa da maƙasudin Ac1, kuma bayan riƙe su na ɗan lokaci, ana sanyaya su a daidai ƙimar da ta dace. Maganin zafi mai zafi na iya canza tsarin da ba shi da kwanciyar hankali da aka samu bayan quenching ko daidaitawa zuwa tsarin tsayayyen tsari don kawar da damuwa da inganta filastik da taurin simintin ƙarfe. Gabaɗaya, tsarin kula da zafin jiki na quenching da zafin jiki mai zafi ana kiransa quenching and tempering treatment. Dole ne a huce simintin karfen da aka kashe a cikin lokaci, kuma ya kamata a huce simintin ƙarfe na yau da kullun idan ya cancanta. Ayyukan simintin gyare-gyare na ƙarfe bayan zafin jiki ya dogara da zafin jiki, lokaci da adadin lokuta. Haɓaka yanayin zafin jiki da tsawaita lokacin riƙewa a kowane lokaci ba zai iya kawai kawar da damuwa na ɓarkewar simintin ƙarfe ba, har ma ya canza maras ƙarfi quenched martensite zuwa yanayin zafi, troostite ko sorbite. An rage ƙarfi da taurin simintin ƙarfe, kuma filastik yana inganta sosai. Ga wasu matsakaici gami karfe tare da alloying abubuwa da karfi samar da carbides (kamar chromium, molybdenum, vanadium da tungsten, da dai sauransu), da taurin ƙara da taurin rage a lokacin da tempering a 400 ℃-500 ℃. Wannan al'amari ana kiransa hardening na biyu, wato, taurin simintin ƙarfe a cikin yanayin zafi ya kai iyakar. A cikin ainihin samarwa, matsakaicin gami da simintin ƙarfe tare da halayen taurin na biyu yana buƙatar yin fushi sau da yawa.

(1) Rashin zafin jiki

Yanayin zafin jiki na ƙananan zafin jiki shine 150 ℃-250 ℃. Low zazzabi tempering iya samun tempered martensite tsarin, wanda aka yafi amfani ga quenching high carbon karfe da kuma quenching high gami karfe. Tempered martensite yana nufin tsarin cryptocrystalline martensite da kyawawan carbides mai kyau. Tsarin ƙarfe na hypoeutectoid bayan ƙarancin zafin jiki yana haɓaka martensite; tsarin hypereutectoid karfe bayan low zazzabi tempering ne tempered martensite + carbides + riƙe austenite. Manufar ƙananan zafin jiki shine don haɓaka ƙarfin ƙarfe mai ƙarewa daidai lokacin da yake riƙe babban taurin (58HRC-64HRC), ƙarfi mai ƙarfi da juriya, yayin da yake rage yawan damuwa da gaggaruwar simintin ƙarfe.

(2) Matsakaicin zafin jiki

The tempering zafin jiki na matsakaici zafin jiki ne kullum tsakanin 350 ℃-500 ℃. Tsarin bayan zafin jiki a matsakaicin zafin jiki shine babban adadin siminti mai laushi mai laushi wanda aka tarwatsa kuma an rarraba akan matrix ferrite, wato, tsarin troostite mai zafi. Ferrite a cikin tsarin troostit mai zafi har yanzu yana riƙe da siffar martensite. An kawar da damuwa na ciki na simintin ƙarfe bayan zafin jiki, kuma suna da iyakacin ƙarfi mafi girma da iyakar yawan amfanin ƙasa, ƙarfin ƙarfi da taurin, da filastik mai kyau da tauri.

(3) Yawan zafin jiki

Matsakaicin zafin jiki na zafin jiki shine 500 ° C-650 ° C, kuma tsarin kula da zafi wanda ya haɗu da quenching da zafin zafin jiki na gaba shine yawanci ake kira quenching and tempering treatment. Tsarin bayan yanayin zafi mai zafi yana da zafi sorbite, wato, siminti mai kyau da ferrite. Ferrite a cikin sorbite mai zafin rai shine ferrite polygonal wanda ke fuskantar recrystallization. Simintin gyare-gyaren ƙarfe bayan zafin zafin jiki yana da ingantattun kayan aikin injiniya dangane da ƙarfi, filastik da tauri. High zafin jiki tempering ne yadu amfani a matsakaici carbon karfe, low gami karfe, da kuma daban-daban muhimman tsarin sassa da hadaddun sojojin.

5) Magani mai ƙarfi

Babban manufar maganin maganin shine narkar da carbides ko wasu matakan da aka haɗe a cikin ingantaccen bayani don samun ingantaccen tsari na lokaci ɗaya. Castings na austenitic bakin karfe, austenitic manganese karfe da hazo hardening bakin karfe kamata gaba daya zama m bayani bi. Zaɓin zafin jiki na maganin ya dogara ne akan abun da ke tattare da sinadarai da zanen lokaci na simintin ƙarfe. The zafin jiki na austenitic manganese karfe simintin gyaran kafa ne kullum 1000 ℃ - 1100 ℃; da zazzabi na austenitic chromium-nickel bakin karfe simintin gyaran kafa ne kullum 1000 ℃-1250 ℃.

Mafi girman abun ciki na carbon a cikin simintin ƙarfe da ƙarin abubuwan haɗaɗɗun abubuwan da ba za a iya narkewa ba, mafi girman zafin maganin sa ya kamata ya kasance. Don hazo tauraruwar simintin ƙarfe mai ɗauke da tagulla, taurin simintin ƙarfe yana ƙaruwa saboda hazo na matakan arziƙin jan ƙarfe a cikin yanayin simintin sanyaya. Domin sassauta tsari da haɓaka aikin sarrafawa, simintin ƙarfe yana buƙatar kulawa da ingantaccen bayani. Its m bayani zafin jiki ne 900 ℃-950 ℃.

6) Maganin Tauraruwar Hazo

Jiyya taurin hazo magani ne mai ƙarfafa tarwatsawa wanda ake gudanarwa a cikin kewayon zafin jiki, wanda kuma aka sani da tsufa na wucin gadi. Ma'anar hazo hardening jiyya shi ne cewa a mafi girma yanayin zafi, carbides, nitrides, intermetallic mahadi da sauran m matsakaici bulan precipitated daga supersaturated m bayani da tarwatsa a cikin matrix, don haka yin simintin gyaran kafa karfe m Ingantattun inji Properties da taurin.

Zazzabi na maganin tsufa kai tsaye yana rinjayar aikin ƙarshe na simintin ƙarfe. Idan yanayin zafin tsufa ya yi ƙasa sosai, lokacin tauraruwar hazo zai yi hazo a hankali; idan yawan zafin jiki na tsufa ya yi yawa, tarawar lokaci mai zurfi zai haifar da wuce gona da iri, kuma ba za a sami mafi kyawun aiki ba. Don haka, wurin samar ya kamata ya zaɓi zafin zafin da ya dace dangane da simintin ƙarfe na simintin ƙarfe da ƙayyadaddun aikin simintin ƙarfe. The tsufa zafin jiki na austenitic zafi-resistant simintin karfe ne kullum 550 ℃-850 ℃; da tsufa zafin jiki na high-ƙarfi hazo hardening Cast karfe ne kullum 500 ℃.

7) Maganin Taimakon Danniya

Manufar maganin zafi na rage damuwa shine kawar da damuwa na simintin gyare-gyare, kashe damuwa da damuwa da aka kafa ta hanyar inji, don daidaita girman simintin. Maganin zafi na rage damuwa gabaɗaya ana yin zafi zuwa 100°C-200°C ƙasa da Ac1, sannan a ajiye shi na ɗan lokaci, sannan a sanyaya shi da tanderu. Tsarin simintin gyare-gyaren ƙarfe bai canza ba a lokacin aikin rage damuwa. Simintin ƙarfe na ƙarfe, simintin ƙarfe mai ƙarancin ƙarfi da simintin ƙarfe mai ƙarfi duk ana iya fuskantar maganin rage damuwa.

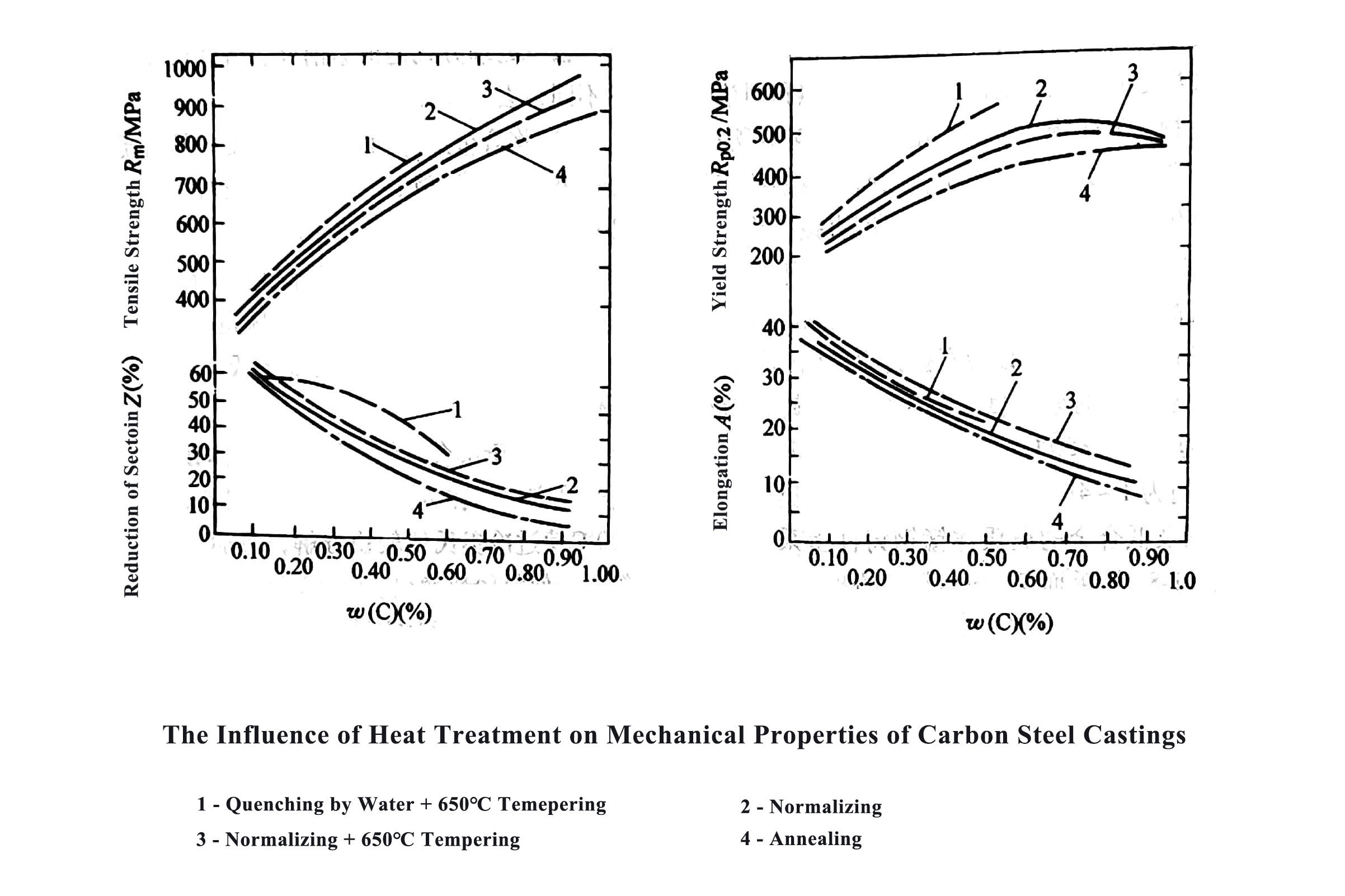

4. Tasirin Maganin Zafi Akan Abubuwan Simintin Karfe

Baya ga aikin simintin karfe dangane da sinadarai da tsarin simintin, ana kuma iya amfani da hanyoyin magance zafi daban-daban don sa ya sami ingantattun kaddarorin inji. Babban maƙasudin tsarin kula da zafi shine haɓaka ingancin simintin gyare-gyare, rage nauyin simintin, tsawaita rayuwar sabis da rage farashi. Maganin zafi wata hanya ce mai mahimmanci don inganta kayan aikin injiniya na simintin gyaran kafa; kayan aikin injiniya na simintin gyare-gyare sune muhimmiyar alama don yin la'akari da tasirin maganin zafi. Baya ga kaddarorin masu zuwa, ginin dole ne kuma yayi la'akari da dalilai kamar hanyoyin sarrafawa, yanke aiki da buƙatun amfani da simintin gyare-gyare a lokacin da ake yin zafi da simintin ƙarfe.

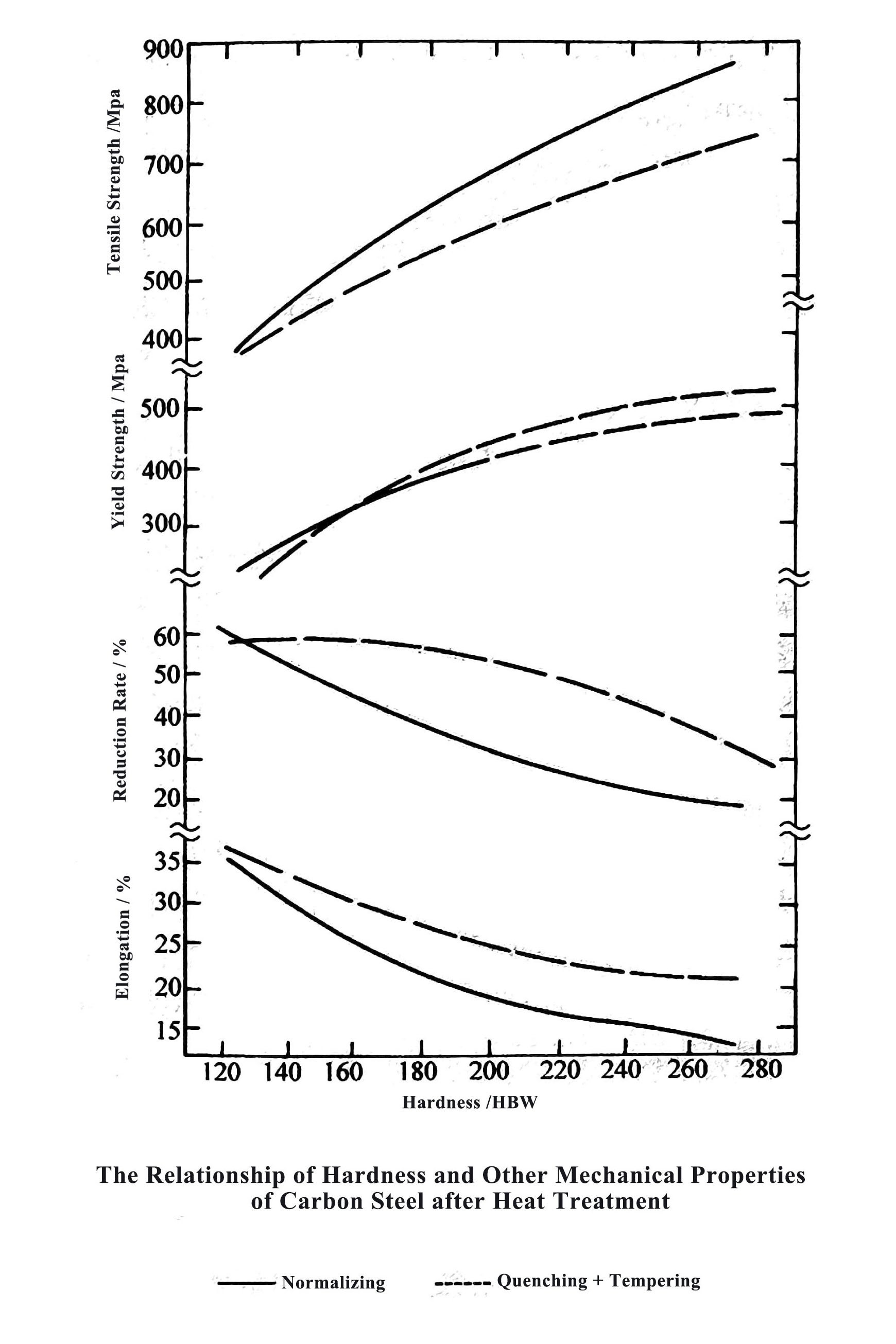

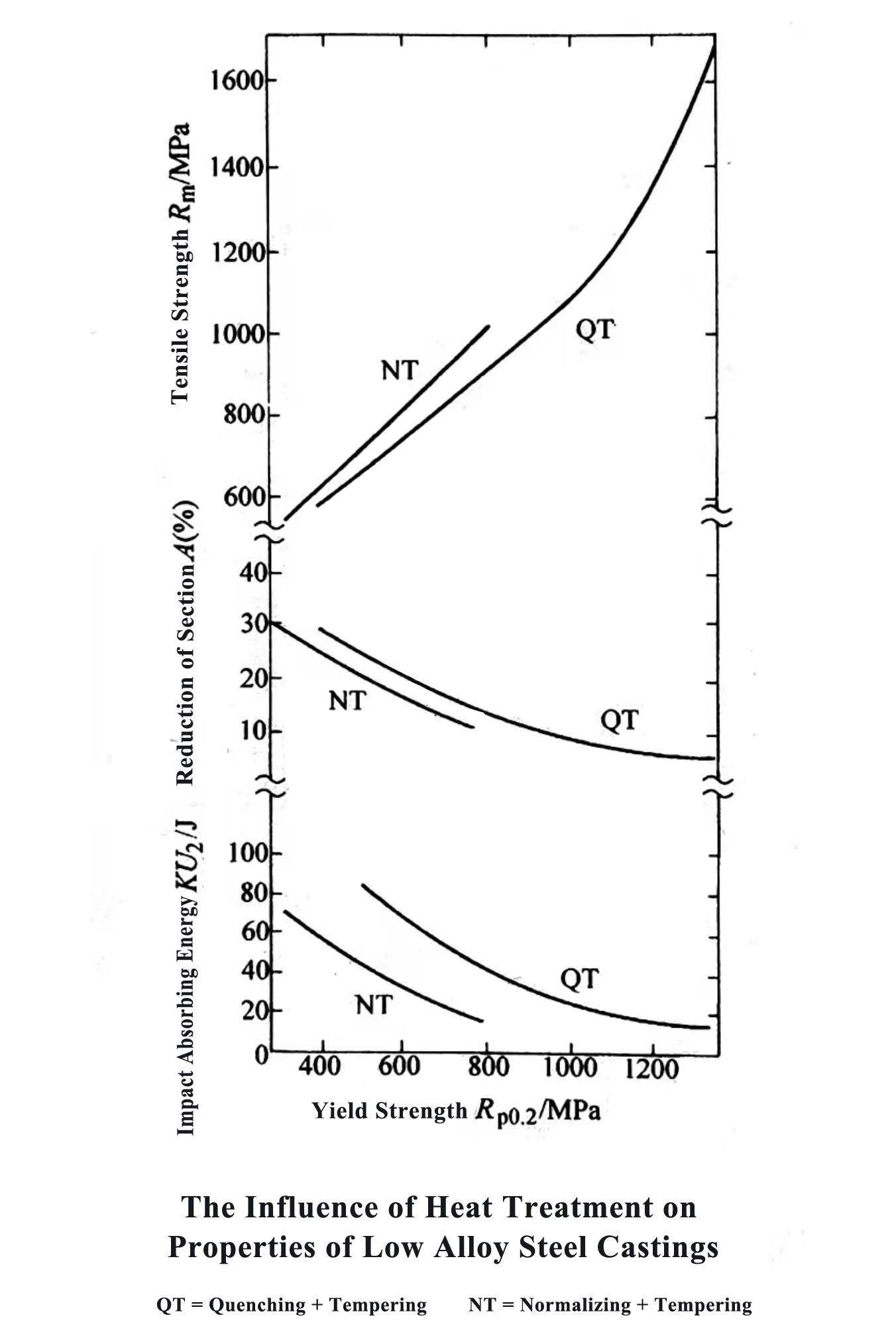

1) Tasirin Maganin Zafi Akan Qarfin Fim

A ƙarƙashin yanayin simintin ƙarfe iri ɗaya, ƙarfin simintin ƙarfe bayan hanyoyin magance zafi daban-daban yana da haɓaka haɓaka. Gabaɗaya magana, ƙarfin jujjuyawar simintin ƙarfe na carbon karfe da ƙananan simintin ƙarfe na ƙarfe na iya kaiwa 414 Mpa-1724 MPa bayan maganin zafi.

2) Tasirin Maganin Zafi Akan Fintinkau Na Simintin Karfe

Tsarin simintin simintin ƙarfe na simintin ƙarfe yana da ƙaƙƙarfa kuma filastik yana da ƙasa. Bayan maganin zafi, za a inganta microstructure da filastik daidai yadda ya kamata. Musamman ma plasticity na simintin ƙarfe bayan quenching da tempering jiyya (quenching + high zafin jiki tempering) za a muhimmanci inganta.

3) Taurin Karfe

Ana yawan kimanta ma'aunin taurin simintin ƙarfe ta gwajin tasiri. Tun da ƙarfi da taurin simintin karfe biyu ne na masu nuna sabani, ginin dole ne ya yi cikakken la'akari don zaɓar tsarin kula da zafi mai dacewa don cimma cikakkiyar kaddarorin injin da abokan ciniki ke buƙata.

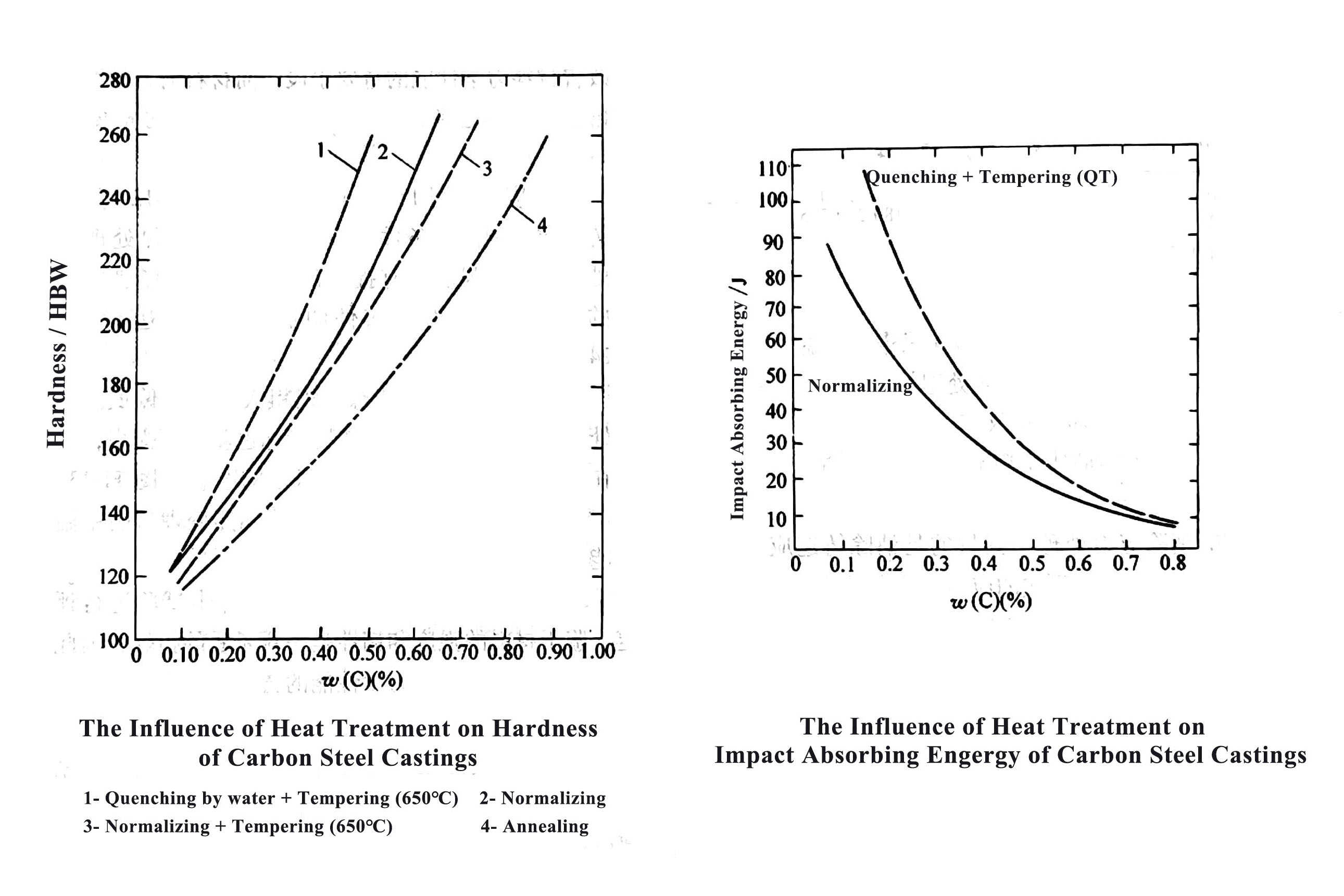

4)Tasirin Maganin Zafi Akan Taurin Simintin

Lokacin da taurin karfen simintin ya kasance iri ɗaya, taurin ƙarfen simintin bayan jiyya na zafi zai iya kusan nuna ƙarfin simintin. Don haka, ana iya amfani da taurin azaman fihirisar fahimta don kimanta aikin simintin ƙarfe bayan maganin zafi. Gabaɗaya magana, taurin simintin ƙarfe na carbon na iya kaiwa 120 HBW - 280 HBW bayan maganin zafi.

Lokacin aikawa: Yuli-12-2021