Masana'antu electrocoating ne yadu amfani da surface jiyya domin kare dakarfe simintin gyaran kafada CNC machining kayayyakin daga lalata da kyau gama. Abokan ciniki da yawa suna yin tambayoyi game da saman jiyya na simintin ƙarfe damadaidaicin sassa na inji. Wannan labarin zai mayar da hankali kan tsarin suturar electrophoretic. Da fatan zai zama taimako ga duk abokan tarayya.

Electrocoating hanya ce ta shafa wanda barbashi irin su pigments da resins da aka dakatar a cikin maganin electrophoretic ke karkata zuwa ƙaura da ajiyewa a saman ɗayan na'urorin lantarki ta hanyar amfani da filin lantarki na waje. An ƙirƙira ka'idar murfin electrophoretic a ƙarshen 1930s, amma an haɓaka wannan fasaha kuma an sami aikace-aikacen masana'antu bayan 1963. Rufin Electrophoretic shine tsarin ginawa mafi amfani ga kayan kwalliyar ruwa. Rufin Electrophoretic yana da halaye na solubility na ruwa, rashin guba, da sauƙin sarrafawa ta atomatik. Domin shi ne dace da surface jiyya na conductive workpieces (karfe simintin gyaran kafa, machined sassa, forgings, sheet karfe sassa da waldi sassa, da dai sauransu), da electrophoretic shafi aiwatar da sauri da aka yi amfani da ko'ina a masana'antu kamar motoci, gini kayan, hardware. , da kayan aikin gida.

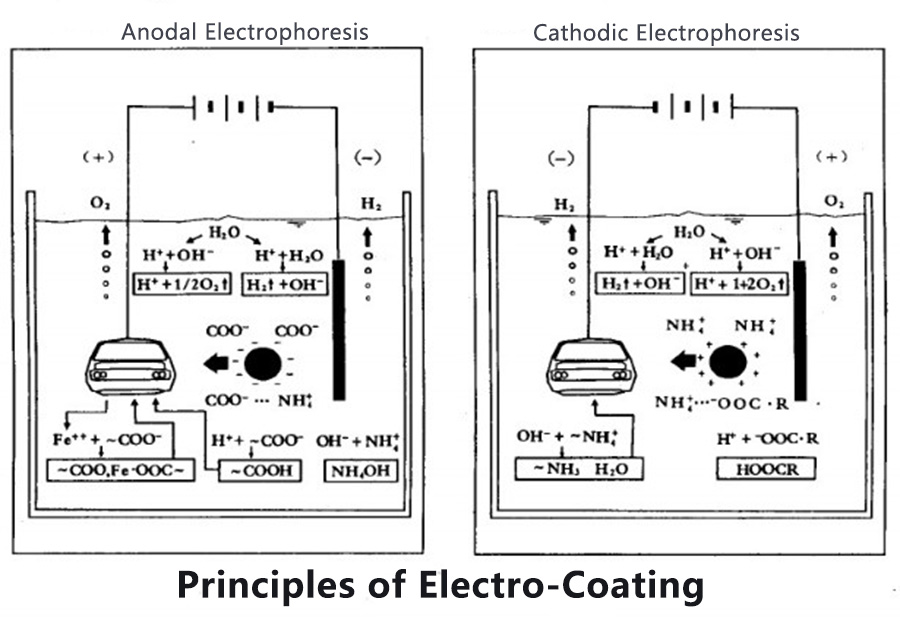

Ka'idoji

Gudun da ke ƙunshe a cikin murfin electrophoretic na cathodic yana da ƙungiyoyi na asali, waɗanda ke samar da gishiri bayan tsaka-tsakin acid kuma ya narke cikin ruwa. Bayan da aka yi amfani da halin yanzu kai tsaye, ion acid radical negative ions suna motsawa zuwa anode, kuma ions resin da pigment barbashi nannade da su suna motsawa zuwa cathode tare da caji mai kyau kuma an ajiye su a kan cathode. Wannan shine ainihin ka'idar shafi na electrophoretic (wanda aka fi sani da plating). Electrophoresis shafi ne mai matukar hadaddun electrochemical dauki, a kalla hudu sakamakon electrophoresis, electrodeposition, electrolysis, da electroosmosis faruwa a lokaci guda.

Electrophoresis

Bayan an kunna anode da cathode a cikin maganin colloidal, ƙwayoyin colloidal suna motsawa zuwa gefen cathode (ko anode) a ƙarƙashin aikin filin lantarki, wanda ake kira electrophoresis. Abubuwan da ke cikin maganin colloidal ba a cikin yanayin kwayoyin halitta da ions ba, amma solute da aka tarwatsa a cikin ruwa. Abun yana da girma kuma ba zai yi hazo cikin yanayin tarwatsewa ba.

Electrodeposition

Abubuwan da ke faruwa na hazo mai ƙarfi daga ruwa ana kiransa agglomeration (agglomeration, deposition), wanda galibi ana samarwa yayin sanyaya ko tattara bayani, kuma murfin electrophoretic ya dogara da wutar lantarki. A cikin murfin electrophoretic na cathodic, abubuwan da aka caje masu inganci suna taruwa akan cathode, kuma barbashi da aka caje mara kyau (watau ions) suna tara akan anode. Lokacin da tabbataccen cajin colloidal barbashi (gudu da pigment) isa cathode (substrate) Bayan surface area (sosai alkaline dubawa Layer), electrons da ake samu da kuma amsa tare da hydroxide ions zama ruwa-insoluble abubuwa, wanda aka ajiye a kan cathode. fenti workpiece).

Electrolysis

A cikin wani bayani tare da ionic conductivity, anode da cathode suna da alaka da kai tsaye halin yanzu, anions suna janyo hankalin zuwa ga anode, da cations suna janyo hankalin zuwa ga cathode, da kuma sinadaran dauki faruwa. Aanode yana haifar da rushewar ƙarfe da oxidation na electrolytic don samar da oxygen, chlorine, da dai sauransu. Aanode shine lantarki wanda zai iya haifar da amsawar oxygen. Ƙarfe yana haɓaka a cathode kuma H + an rage shi ta hanyar electrolytically zuwa hydrogen.

Electroosmosis

Bayan ƙare biyu (cathode da anode) na mafita tare da nau'i daban-daban da aka raba ta hanyar membrane na semipermeable suna ƙarfafawa, abin da ke haifar da ƙananan ƙaddamarwa yana motsawa zuwa ga babban taro ana kiransa electroosmosis. Fim ɗin da aka saka kawai a saman abin da aka rufe shi ne fim ɗin da ba zai iya jurewa ba. A karkashin ci gaba da aikin wutar lantarki, ruwan da ke cikin smearing film dialysis ya fita daga cikin fim kuma ya motsa zuwa wanka don zubar da fim din. Wannan shi ne electroosmosis. Electroosmosis juya da hydrophilic shafi film a cikin wani hydrophobic shafi film, da dehydration sa shafi film m. Za a iya taɓa fentin rigar bayan yin iyo tare da fenti mai kyau na electro-osmosis electrophoretic ba mai ɗaure ba. Kuna iya kurkura ruwan wanka yana manne da rigar fim ɗin fenti da ruwa.

Halayen Electrocoating

Electrophoretic fenti fim yana da abũbuwan amfãni daga cika, uniformity, flatness da m shafi. A taurin, mannewa, lalata juriya, tasiri yi, da kuma permeability na electrophoretic Paint film ne muhimmanci fiye da sauran shafi matakai.

(1) Ana amfani da fenti mai narkewa da ruwa, ana amfani da ruwa azaman matsakaicin narkar da ruwa, wanda ke ceton ɗimbin kaushi mai yawa, yana rage gurɓataccen iska da haɗarin muhalli, yana da aminci da tsafta, kuma yana guje wa ɓoyayyun haɗarin wuta;

(2) Ayyukan zanen yana da girma, asarar fenti kadan ne, kuma yawan amfani da fenti na iya kaiwa 90% zuwa 95%;

(3) Kauri na fim ɗin ya zama uniform, mannewa yana da ƙarfi, kuma ingancin sutura yana da kyau. Kowane bangare na workpiece, kamar ciki Layer, depressions, welds, da dai sauransu, na iya samun uniform da santsi shafi fim, wanda warware matsalar sauran shafi hanyoyin da hadaddun-dimbin yawa workpieces. Matsalar fenti;

(4) Ayyukan samarwa yana da girma, kuma ginin zai iya gane atomatik da ci gaba da samarwa, wanda ke inganta ingantaccen aiki;

(5) Kayan aiki yana da rikitarwa, farashin zuba jari yana da yawa, yawan amfani da wutar lantarki yana da yawa, zafin jiki da ake buƙata don bushewa da warkewa yana da yawa, sarrafa fenti da zane yana da rikitarwa, yanayin ginin yana da tsauri, kuma ana buƙatar maganin sharar gida. ;

(6) Za a iya amfani da fenti mai narkewa mai ruwa kawai, kuma ba za a iya canza launi ba yayin aikin sutura. Zaman lafiyar fenti ba shi da sauƙin sarrafawa bayan ajiya na dogon lokaci.

(7) Kayan aikin lantarki na lantarki yana da rikitarwa kuma kayan fasaha yana da girma, wanda ya dace da samar da launi mai tsabta.

Iyakar Electrocoating

(1) Ya dace ne kawai don suturar firam na abubuwan sarrafa abubuwa kamar sassan injinan ƙarfe na ƙarfe da ƙarfe mara ƙarfe. Ba za a iya lulluɓe abubuwan da ba sa aiki kamar itace, filastik, zane, da sauransu da wannan hanyar.

(2) Electrophoretic shafi tsari bai dace da mai rufi abubuwa hada da mahara karafa, idan electrophoresis halaye ne daban-daban.

(3) Ba za a iya amfani da tsarin suturar Electrophoretic don abubuwa masu rufi waɗanda ba za su iya tsayayya da zafin jiki ba.

(4) Rufin Electrophoretic bai dace da sutura tare da ƙayyadaddun buƙatu akan launi ba. Electrophoretic shafi na launuka daban-daban yana buƙatar fentin su a cikin ramuka daban-daban.

(5) Ba a ba da shawarar murfin Electrophoretic don samar da ƙaramin tsari ba (lokacin sabunta wanka ya fi watanni 6), saboda saurin sabuntawa na wanka yana da jinkirin, guduro a cikin wanka yana tsufa kuma abubuwan da ke cikin narkewa suna canzawa. sosai. Wanka ba shi da kwanciyar hankali.

Matakan Electrocoating

(1) Domin electrophoretic shafi na general karfe saman, da tsari kwarara ne: pre-tsaftacewa → degeneasing → ruwa wanka → tsatsa cire → ruwa wanka → neutralization → ruwa wanka → phosphating → ruwa wanka → passivation → electrophoretic shafi → tank top Cleaning → ultrafiltration ruwa wanka → bushewa → offline.

(2) Ƙarƙashin ƙwayar cuta da pretreatment na abu mai rufi yana da tasiri mai girma akan fim ɗin suturar electrophoretic. Ana lalata simintin ƙarfe gabaɗaya ta hanyar yashi ko harbin iska, ana amfani da zaren auduga don cire ƙura mai iyo a saman kayan aikin, kuma ana amfani da takarda yashi don cire ragowar harbe-harben ƙarfe da sauran tarkace a saman. Ana kula da saman karfe tare da ragewa da cire tsatsa. Lokacin da buƙatun saman suka yi yawa, ana buƙatar jiyya na phosphating da wucewar ƙasa. Ferrous karfe workpieces dole ne a phosphated kafin anodic electrophoresis, in ba haka ba da lalata juriya na Paint fim zai zama matalauta. A cikin jiyya na phosphating, an zaɓi fim ɗin gishirin gishiri na zinc gabaɗaya, tare da kauri na kusan 1 zuwa 2 μm, kuma ana buƙatar fim ɗin phosphate don samun lu'ulu'u masu kyau da iri ɗaya.

(3) A cikin tsarin tacewa, gabaɗaya ana karɓar tacewa ta farko, kuma tacewa tsarin jakar raga ne. Ana jigilar fentin electrophoretic zuwa tacewa ta hanyar famfo a tsaye don tacewa. Yin la'akari da cikakkiyar sake zagayowar maye gurbin da ingancin fim ɗin fenti, jakar tacewa tare da girman pore na 50μm shine mafi kyau. Ba kawai zai iya saduwa da ingancin buƙatun fim ɗin fenti ba, amma kuma yana magance matsalar rufe jakar tacewa.

(4) Girman tsarin wurare dabam dabam na murfin electrophoretic kai tsaye yana rinjayar kwanciyar hankali na wanka da ingancin fim din fenti. Ƙara yawan adadin wurare dabam dabam yana rage hazo da kumfa na ruwan wanka; duk da haka, tsufa na ruwan wanka yana haɓaka, yawan amfani da makamashi yana ƙaruwa, kuma kwanciyar hankali na ruwan wanka ya zama mafi muni. Yana da kyau don sarrafa lokutan sake zagayowar ruwa na tanki zuwa sau 6-8 / h, wanda ba wai kawai tabbatar da ingancin fim ɗin fenti ba, amma kuma yana tabbatar da kwanciyar hankali na aikin tanki.

(5) Yayin da lokacin samarwa ya karu, rashin daidaituwa na diaphragm na anode zai karu kuma ingantaccen ƙarfin aiki zai ragu. Sabili da haka, a cikin samarwa, ƙarfin aiki na wutar lantarki ya kamata a hankali a hankali bisa ga asarar wutar lantarki don ramawa juzu'in ƙarfin lantarki na diaphragm na anode.

(6) Tsarin ultrafiltration yana sarrafa ƙaddamar da ions na ƙazanta wanda aikin aikin ya kawo don tabbatar da ingancin sutura. A cikin aikin wannan tsarin, ya kamata a lura cewa da zarar tsarin yana aiki, ya kamata ya ci gaba da gudana kuma an haramta shi sosai don yin aiki na lokaci-lokaci don hana ultrafiltration membrane bushewa. Busassun guduro da pigment suna manne da membrane na ultrafiltration kuma ba za a iya tsaftace su sosai ba, wanda zai yi tasiri sosai ga iyawar ruwa da rayuwar sabis na membrane ultrafiltration. Yawan fitowar ruwa na membrane ultrafiltration yana nuna yanayin ƙasa tare da lokacin gudu. Ya kamata a tsaftace shi sau ɗaya don kwanaki 30-40 na ci gaba da aiki don tabbatar da ruwan ultrafiltration da ake buƙata don leaching ultrafiltration da wankewa.

(7) Hanyar suturar electrophoretic ta dace da tsarin samar da babban adadin layin taro. Zagayowar sabuntawa na wankan electrophoresis yakamata ya kasance cikin watanni 3. Gudanar da ilimin kimiyya na wanka yana da matukar muhimmanci. Ana gwada sigogi daban-daban na wanka akai-akai, kuma ana gyara wanka kuma ana maye gurbinsu bisa ga sakamakon gwajin. Gabaɗaya, ana auna ma'auni na maganin wanka a mitar mai zuwa: ƙimar pH, ingantaccen abun ciki da haɓakawa na maganin electrophoresis, maganin ultrafiltration da ultrafiltration tsaftacewa bayani, anion (anode) bayani na iyakacin duniya, ruwan shafa mai kewayawa, da maganin tsaftacewa deionization sau ɗaya. rana daya; Matsakaicin tushe, abun ciki mai narkewa, da gwajin ƙaramin tanki na dakin gwaje-gwaje sau biyu a mako.

(8) Domin kula da ingancin fim ɗin fenti, yakamata a rika duba daidaito da kauri da fim ɗin fenti akai-akai, kuma kada kamannin su kasance da ramuka, sagging, bawon lemu, wrinkles, da sauransu. alamomi irin su mannewa da juriya na lalata fim din. Zagayen dubawa ya dace da ƙa'idodin binciken masana'anta, kuma gabaɗaya kowane tsari yana buƙatar bincika.

Maganin Sama Kafin Electrophoresis

A surface jiyya na workpiece kafin shafi ne wani muhimmin ɓangare na electrophoretic shafi, yafi shafe degreasing, tsatsa kau, surface kwandishan, phosphating da sauran matakai. Kyakkyawan maganin sa ba kawai yana rinjayar bayyanar fim din ba, yana rage aikin anti-lalata, amma kuma yana lalata kwanciyar hankali na maganin fenti. Saboda haka, ga surface na workpiece kafin zanen, shi ake bukata don zama free of man stains, tsatsa alamomi, babu pretreatment sunadarai da phosphating sedimentation, da dai sauransu, kuma phosphating fim yana da m da kuma uniform lu'ulu'u. Game da matakai daban-daban kafin magani, ba za mu tattauna su daban-daban ba, amma kawai gabatar da wasu abubuwan kulawa:

1) Idan raguwa da tsatsa ba su da tsabta, ba kawai zai shafi samuwar fim din phosphating ba, amma kuma zai shafi ƙarfin haɗin gwiwa, aikin ado da kuma juriya na lalata. Fim ɗin fenti yana da haɗari ga raguwa da raguwa.

2) Phosphating: Manufar ita ce don inganta mannewa da ikon hana lalata na fim ɗin electrophoretic. Matsayinsa kamar haka:

(1) Saboda tasirin jiki da na sinadarai, an haɓaka mannewa na fim ɗin suturar kwayoyin halitta zuwa ma'auni.

(2) Fim ɗin phosphating yana jujjuya saman ƙarfe daga mai gudanarwa mai kyau zuwa maras kyau, ta haka yana hana haɓakar micro-batura akan saman ƙarfe, yadda ya kamata ya hana lalatawar rufin, da haɓaka juriya na lalata da juriya na ruwa. shafi. Bugu da ƙari, kawai a kan tushen ƙasa mai zurfi da raguwa, za a iya samar da fim mai gamsarwa na phosphating a kan tsabta mai tsabta, uniform, da man shafawa. Daga wannan bangare, fim din phosphating da kansa shine mafi mahimmanci kuma abin dogara akan sakamakon tsarin da aka rigaya.

3) Wankewa: Kyakkyawan wankewa a kowane mataki na pretreatment zai sami babban tasiri a kan ingancin dukan pretreatment da fenti fim. Tsabtace ruwa na ƙarshe kafin zanen, tabbatar da cewa dripping conductivity na abu mai rufi bai fi 30μs/cm ba. Tsaftacewa ba ta da tsabta, kamar kayan aikin:

(1) Residual acid, phosphating sinadaran ruwa, flocculation na guduro a cikin fenti ruwa, da tabarbarewar kwanciyar hankali;

(2) Sauran abubuwan waje (tabon mai, ƙura), raguwar ramuka, barbashi da sauran lahani a cikin fim ɗin fenti;

(3) Ragowar electrolytes da salts suna haifar da haɓaka halayen electrolysis kuma suna haifar da ƙumburi da sauran cututtuka.

Lokacin aikawa: Afrilu-17-2021