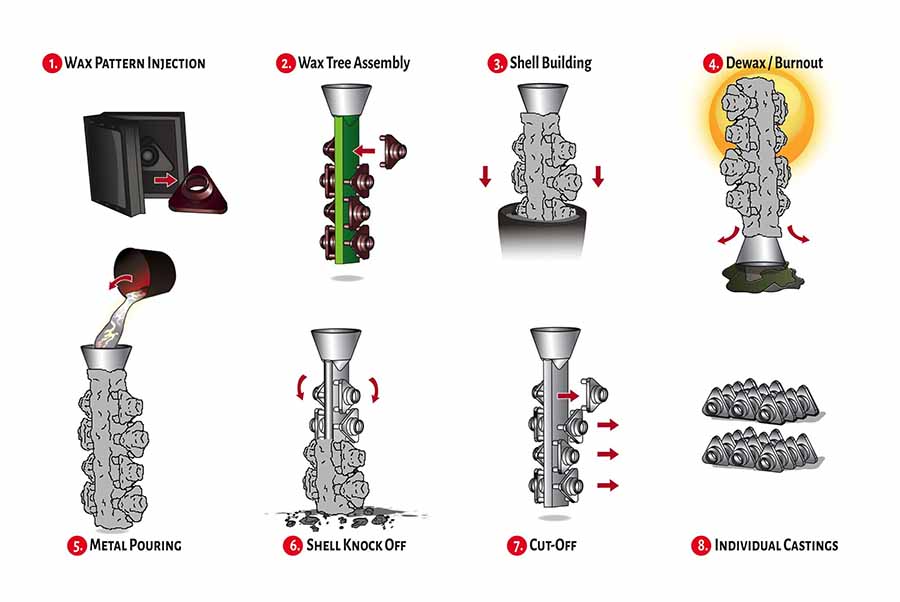

Zuba jariyana amfani da ƙirar kakin zuma da aka samar ta kayan aiki na musamman da na musamman kamar yadda ake buƙata. Samfurin kakin zuma (kwaikwai) suna kewaye da yadudduka na kayan da aka ɗaure da su don samar da harsashi mai ƙarfi don tsayayya da narkakkar karafa da gami. Tsarin de-wax zai cire kakin zuma don ba da damar rami mara zurfi don haka narkakken ƙarfe ya cika su don samar da sassan simintin da ake so. Shi ya sa ake kuma kiran simintin saka hannun jarin tsarin simintin kakin zuma da ya ɓace. A cikin masana'antar simintin saka hannun jari na zamani, kayan haɗin gwiwa galibi ana nufin silica sol da gilashin ruwa, wanda zai iya tabbatar da kyakkyawan farfajiyar.zuba jari simintin gyaran kafa. Ana amfani da tsarin simintin saka hannun jari sau da yawa don samar da simintin ƙarfe na ƙarfe, simintin ƙarfe na gami,bakin karfe simintin gyaran kafada simintin gyare-gyaren tagulla. Anan a cikin wannan labarin, muna ƙoƙarin gabatar da manyan matakai na saka hannun jari.

Haɓaka kayan aikin don allurar kakin zuma

Bisa ga simintin gyare-gyaren da ake so da kuma la'akari da ba da izinin yin aikin injiniya da yuwuwar raguwa, injiniyoyi a wurin samar da simintin zuba jari ya kamata su tsara da kuma samar da samfurin a cikin karfe (wanda kuma ake kira "mutu") da kayan aiki don samar da tsarin kakin zuma.

Ƙirƙirar Tsarin Kakin zuma

A zamanirasa kakin simintin kafa, ƙirar kakin zuma yawanci ana yin su ta hanyar allurar kakin zuma a cikin kayan aikin ƙarfe ko “mutu” tare da injunan allura na musamman. Don yin simintin gyare-gyare da yawa, kayan aikin silicon galibi ana yin su ne daga sassakawar mawaƙin kuma ana allura da kakin zuma a cikin rami da ya haifar.

Kakin Bishiyar Taro

Yawanci rashin tattalin arziƙi ne yin ƙananan sassa ɗaya bayan ɗaya, don haka ƙirar kakin zuma galibi ana haɗe shi da kakin zuma. Ana kiran kakin da ke tsakanin ƙirar (s) da sprue ƙofofi, saboda suna murƙushe alkibla da kwararowar narkakkar gami a cikin ɓangarorin da tsarin ya yi. Sprue yana amfani da dalilai biyu

- 1. Yana ba da wani wuri mai hawa don haɗa nau'i-nau'i masu yawa a cikin tsari guda ɗaya, wanda daga baya za a cika shi da gami.

- 2. Yana ba da hanyar kwarara don gwal ɗin da aka narkar da su zuwa cikin ɓangarorin da ƙirar kakin zuma ta haifar.

Ginin Shell

Mataki na gaba a cikin tsari shine gina harsashi yumbu a kusa da itacen kakin zuma. Wannan harsashi a ƙarshe zai zama gyambon da ake zuba ƙarfe a ciki. Don gina harsashi, ana tsoma bishiyar a cikin wanka na yumbu ko slurry. Bayan tsoma, yashi mai kyau ko kuma a shafa shi a saman rigar. Ana barin ƙurar ta bushe, kuma ana maimaita tsarin sau da yawa har sai wani nau'in yumbu mai laushi, wanda zai iya tsayayya da matsalolin narkakkar karfe da gami yayin aikin zubar da ruwa.

Dewax / Burnout

Kafin zuba karfe a cikin kwandon, ana cire kakin zuma ta hanyar dumama harsashi. Ana yin wannan yawanci a cikin autoclave-dewax autoclave, wanda yayi kama da babban tukunyar matsa lamba na masana'antu. Wata hanyar kuma ita ce amfani da tanda mai walƙiya, wanda ke narkewa kuma yana ƙone kakin zuma. Za a iya tattara kakin zuma kuma a sake amfani da shi don yin tsarin kakin zuma na gaba. Yawancin masana'antar simintin saka hannun jari suna amfani da hanyoyin biyu a cikin kide kide. Wuta mai walƙiya tana ƙone ragowar kakin zuma kuma tana warkar da harsashi, a shirye don karɓar narkakken ƙarfe da gami.

Zuba Ƙarfe

Kafin a zuba karfen a cikin yumbu ko harsashi, ana ɗora ƙuran zuwa wani takamaiman zafin jiki don hana narkakkar gaɗaɗɗen daga ƙarfi ko daskarewa kafin a cika ƙurar gabaɗaya. Ana narke gami a cikin kofin yumbu (wanda ake kira crucible) ta hanyar amfani da tsari da aka sani da narkewar shigar. Ƙarfin wutar lantarki mai girma yana haifar da filin maganadisu a kusa da gami, yana samar da filayen lantarki a cikin ƙarfe (eddy currents). Wuraren daɗaɗɗen zazzaɓi suna zafi da gami saboda juriya na kayan. Lokacin da gwangwani ya kai ƙayyadadden zafin jiki, ana zuba shi a cikin ƙirar, kuma ana barin ƙwayar ta yi sanyi.

Shell Kashe

Da zarar an yi sanyi, ana cire kayan harsashi daga karfe ta hanyoyin injina kamar guduma, fashewar ruwan matsa lamba ko tebur mai girgiza. Hakanan za'a iya cika cirewar Shell ta hanyar sinadarai, ta amfani da maganin zafi mai zafi na ko dai potassium hydroxide ko sodium hydroxide, amma ana kawar da wannan hanyar saboda matsalolin muhalli da lafiya.

Yanke

Da zarar an cire kayan harsashi, ana yanke sprue da ƙofofin da hannu ko ta hanyar tsintsiya, yankan Laser na tocila. Yankunan yankan suna buƙatar niƙa a cikin wuri mai kyau.

Simintin Ɗaukakin Mutum

Bayan an cire sassan daga sprue, kuma an cire ƙofofi, ana iya ƙare saman ta hanyoyi da yawa kamar vibratory, ƙarewar watsa labaru, beling, niƙa hannu, gogewa. Ana iya gamawa da hannu, amma a yawancin lokuta ana sarrafa shi ta atomatik.Simintin gyare-gyaresa'an nan a duba, yi alama (idan an buƙata), kunshe da jigilar kaya. Dangane da aikace-aikacen, ana iya amfani da sassan simintin saka hannun jari a cikin “siffar hanyar sadarwar su” ko kuma a shainjidon madaidaicin saman.

Lokacin aikawa: Janairu-18-2021