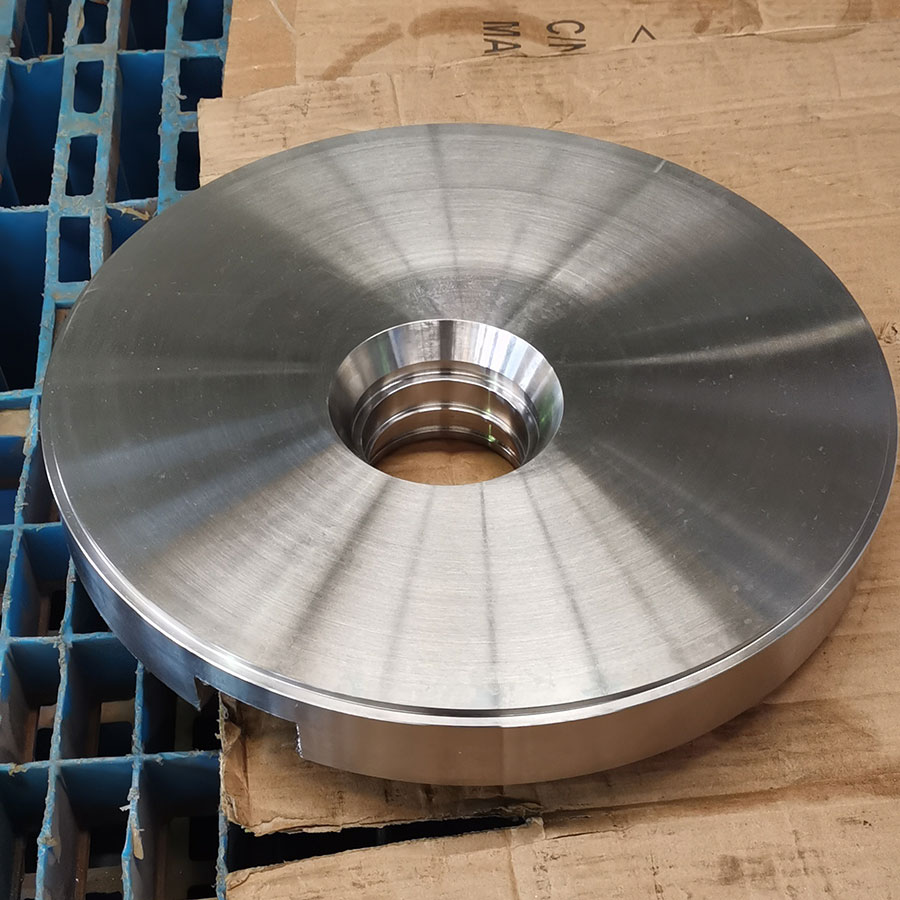

Ana kuma kiran simintin ƙwaƙƙwaranzuba jari. Wannan aikin simintin yana rage girman ko baya yanke yayin aikin simintin. Hanya ce ta simintin simintin gyare-gyare tare da aikace-aikace masu yawa, daidaiton girman girman simintin, da ingantaccen ingancin saman. Ba a cikin yanayin zafi mai tsananin zafi ba, kuma ya fi dacewa da simintin gyare-gyare a cikin ingantattun masana'antu kamar sararin samaniya da tsaron ƙasa. Ita ce ta farko da ta yi amfani da hanyar simintin bakin karfe na daidaitaccen simintin gyare-gyare don jefa rigunan turbine a cikin babbar injin ta a lokacin. Samfurin da aka gama ya sami yabo ta kowane bangare, kuma wannan hanyar an inganta shi sosai. Bakin ƙarfe madaidaicin simintin gyare-gyaren fasaha ne a cikin masana'antar ganowa, amma ya bambanta da masana'antar kamun kifi na gargajiya saboda ƙarin ƙimardaidaitattun samfuran simintin gyare-gyareya fi girma.

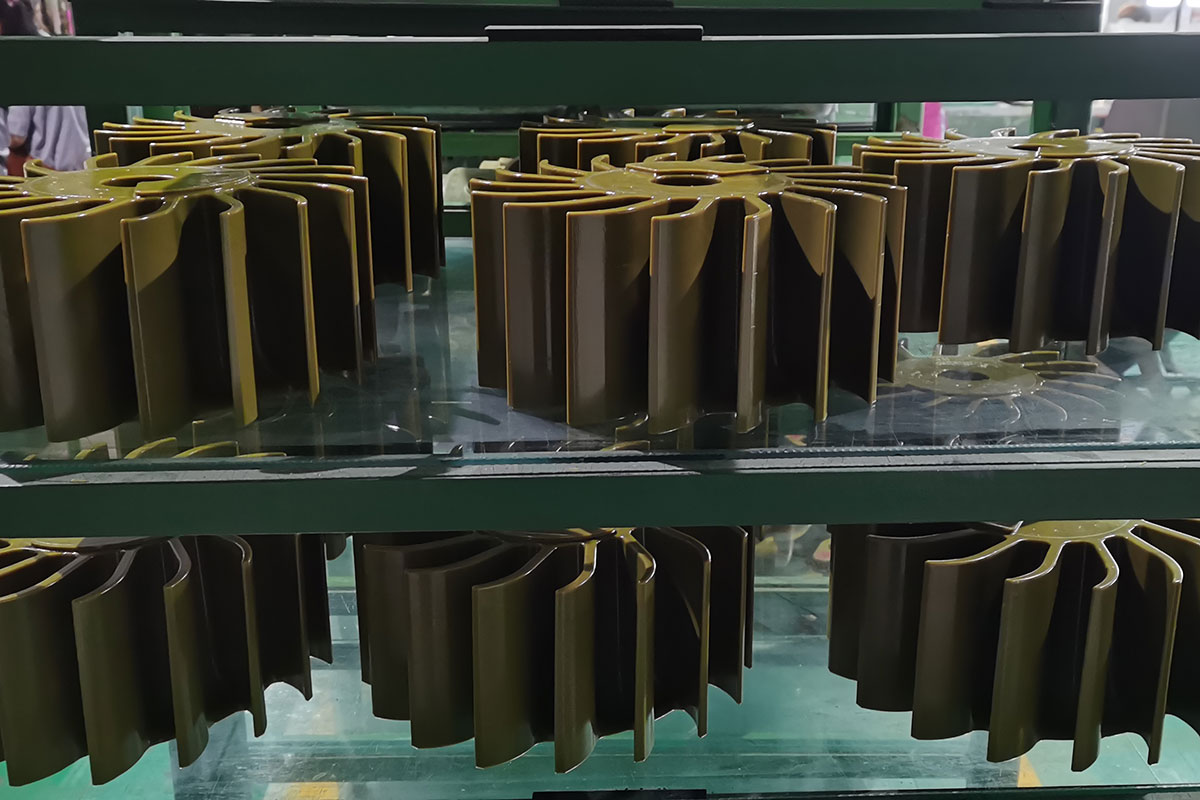

Tsarin Silica Sol Shell

Ana amfani da tsarin yin harsashi na silica sol gabaɗaya a cikin injunan simintin ɓangarorin injin konewa na ciki. Rufin da aka yi amfani da shi a cikin wannan hanya yana da kwanciyar hankali mafi kyau, baya buƙatar tsarin taurin sinadarai, yana da tsayayya ga yanayin zafi, kuma yana da mafi kyawun juriya ga lalacewa. Duk da haka, wannan fasaha kuma tana da wannan ƙayyadaddun ƙayyadaddun ƙayyadaddun, wato, zafi na kakin zuma ba shi da kyau, wanda za'a iya inganta shi ta hanyar ƙara surfactants, amma zai kara zuba jari zuwa wani matsayi.

Tsarin Ruwa Gilashin Shell

An kirkiro wannan hanya da wuri. Kasarmu ma ta bullo da wannan fasaha daga Tarayyar Soviet a shekarun 1950 da 1960. Wannan hanyar tana da ƙarancin farashi, ingantacciyar aiki mai sauƙi, da ƙarancin buƙatun albarkatun ƙasa. Ainihin halaye na tsari amfani da paraffin-stearic acid low-zazzabi mold abu, da kuma ɗaure a cikin harsashi yin tsari amfani da gilashin ruwa, wanda aka yadu amfani a bakin karfe madaidaicin simintin gyaran kafa. Koyaya, babbar matsalar wannan hanyar idan aka kwatanta da tsarin yin harsashi na silica shine cewa ingancin saman simintin gyare-gyaren da aka samu matsakaita ne kuma daidaiton girman yana da ƙasa. Tun bayan bullo da wannan fasaha, an sami ingantuwa da yawa, musamman ta fuskoki masu zuwa:

1. Inganta murfin harsashi.

Babban haɓakawa shine ƙara wani adadin yumbu mai jujjuyawa zuwa murfin baya na harsashi, wanda ke haɓaka ƙarfin harsashi sosai, kuma yana gane gasasshen harsashi ɗaya da harbi.

2. Inganta hardener.

Hardener na gargajiya galibi yana amfani da ammonium chloride, amma wannan abu zai saki adadin ammonia da iskar iskar nitrogen oxide yayin aikin simintin, wanda zai gurɓata yanayi. Don haka, ana amfani da maganin chloride na aluminium a maimakon haka, kuma ana ƙara yin amfani da kristal aluminum chloride. Tasirin wakili yayi kama da na ammonium chloride, amma a cikin 'yan shekarun nan, yin amfani da magnesium chloride hardener yana da fa'ida mai girma ta fuskar saurin ƙarfi da ragowar, don haka yanzu ya fi son yin amfani da magnesium chloride a matsayin mai taurin. .

3. Haɗaɗɗen harsashi.

Saboda ingancin farfajiyar harsashi na rufin gilashin ruwa yana da wasu lahani, yawancin sassa na asali an jefa su cikin nau'i na nau'i mai nau'i mai nau'i mai nau'i mai nau'i mai nau'i, wanda ke adana farashi a gefe guda kuma yana inganta yanayin simintin a daya hannun. hannu.

4. Ci gaban sababbin fasaha.

A halin yanzu, sabbin hanyoyin da suka balaga ya kamata su zama tsarin simintin gyare-gyare na kai-da-kai, kumfa filastik mold, narkakken harsashi da sauran matakai. Waɗannan hanyoyin suna da manyan fa'idodi a wasu fannoni, amma haɓakawa na gaba zai jawo hankalin ma'aikatan kimiyya da fasaha.

Amfani da Kere-Tsaren Fasaha da yawa tare da Fasahar Samar da Sauri

Ƙirƙirar ƙira da ƙirar ƙira a cikin aiwatar da ƙirar bakin karfe daidaitaccen simintin gyare-gyaren kakin zuma sun fi rikitarwa kuma suna ɗaukar lokaci, amma fasahar ƙira da sauri na iya daidaita wannan gazawar. Ba za a iya aiwatar da fasahar samfuri cikin sauri kaɗai ba saboda ƙayyadaddun kayan aiki, da yawa a cikin 'yan shekarun nan Amfani da fasahar polymer don samun siffar zagaye na simintin gyare-gyare, sa'an nan kuma ƙera ƙirar kakin zuma, wanda ake amfani da shi a cikin madaidaicin simintin ƙarfe. Misali, fasahar sarrafa haske mai girma uku (SLA) da fasaha mai zaɓaɓɓen Laser sintering (SLS). Waɗannan fasahohin biyu a halin yanzu fasaha ce balagaggu da ake amfani da su a haɗe tare da zuba jari. Fasahar SLA na iya samar da daidaiton girman girma, musamman ga sassa. Daidaitaccen farfajiyar waje, SLS, zuwa wani ɗan lokaci, albarkatun ƙasa suna da ɗan rahusa, amma daidaito kuma yana da takamaiman rata idan aka kwatanta da fasahar SLA, wanda ya dace da wasu aikin simintin gyare-gyare tare da buƙatun farashi. Duk da haka, har yanzu yana da mahimmanci a mai da hankali don sarrafa maɓalli na haɗin gwiwar fasahar ƙira da sauri da fasahar simintin bakin karfe daidai lokacin amfani, kamar cikakken la'akari da sarrafa farashi da daidaiton simintin sassa, da zaɓin ma'aunin ma'auni mai dacewa shine fasahar samfur mai sauri. da fasahar simintin saka hannun jari. Mahimmin batu na haɗin gwiwar kwayoyin halitta.

Yin amfani da fasaha da yawa tare da Fasahar Kwamfuta

Tsarin tsarawa da inganta aikin a cikin tsarin simintin bakin karfe daidaitaccen tsarin simintin gyare-gyaren aiki ne mai ɗaukar aiki da ɗaukar lokaci. A cikin 'yan shekarun nan, tare da ci gaba da haɓaka fasahar kwamfuta, yawancin masana'antu waɗanda ke buƙatar ƙididdiga masu yawa da ƙididdiga daidaitattun ƙididdiga sun ƙaddamar da aikin kwamfuta, kuma daidai da haka an ƙirƙira software daban-daban na lissafi, kamar ProCAST, AutoCAD, AFSolid, Anycasting da sauran software. . Waɗannan softwares na iya ƙididdigewa ko kwaikwaya ƙira da tsarin simintin gyare-gyare na madaidaicin simintin bakin karfe. Za a iya inganta tsarin haɓakawa na yanzu ta hanyar lissafin bayanai. Ci gaban simintin gyare-gyare ya taka rawar gani sosai wajen haɓakawa. Koyaya, a cikin tsarin amfani na yanzu, mun kuma gano cewa ya kamata mu mai da hankali kan aiwatar da ƙirar ƙirar software da ma'aunin thermophysical na kayan kanta. Kyakkyawan mafita ga waɗannan matsalolin na iya rage haɓaka lokacin haɓaka daidaitaccen simintin bakin karfe.

Lokacin aikawa: Oktoba-21-2021