Kamar yadda muka sani, saka hannun jari yana haifar dasimintin gyare-gyaretare da daidaito daidai da kyakkyawan gamawa. Duk da haka, a lokacin samar da tsari nazuba jari, akwai yuwuwar lahani gama gari gama gari. Dangane da kwarewar injiniyarmu da kayan aikin ci gaba, za mu iya samun hanyar hana irin waɗannan matsalolin ta hanyar nazarin abubuwan da ke haifar da su. A ƙasa, mun gabatar da lahani na yau da kullun na simintin gyaran kafa da dalilai da hanyoyin rigakafi. Da fatan wannan labarin zai taimaka wa abokan cinikinmu su fahimci matsalolin kuma ga abokan aikinmu, wannan bincike zai iya taimaka muku hana lahani na simintin gyaran kafa.

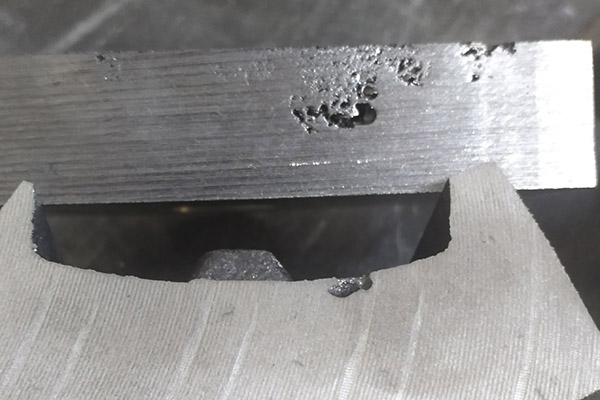

Ƙarƙashin shinge da shinge mai sanyi

1. Bayanin matsala:

Ƙarƙashin ƙaddamarwa sau da yawa ba shi da nama a gida a cikin siririyar bangon simintin ko kuma nesa da mai gudu na ciki, kuma gefensa yana da siffar baka. Bangaren sanyi shine cewa narkakkar karfe biyu ba a haɗa su gaba ɗaya ba kuma akwai haɗin gwiwa a bayyane.

2. Domin:

1) Low narkakkar karfe zuba zafin jiki da mold zafin jiki

2) Zuba gudun yana jinkirin ko saitin mai gudu ba shi da ma'ana, kwararar ƙarfe ya yi tsayi da yawa

3) Kaurin bangon simintin ya yi tsayi da yawa, kuma kwararar narkakkar karfe ba ta da kyau

4) Yanke yayin zubawa

3. Matakan rigakafi:

1) Ƙara narkakkar karfe zuba zafin jiki da mold zafin jiki

2) Ƙara saurin zubewa ko ƙara lamba ko yanki na mai gudu na ciki don rage kwararar narkakkar karfe.

3) Ƙara matsi na kan mai zubar da ruwa don hana yankewa yayin zubarwa

Ragewa

1. Bayanin matsalar:

Ana iya samun ta ta hanyar duban X-ray. Ana iya samun raguwar saman ta hanyar kyalli ko duba tabo. A lokuta masu tsanani, ana iya samun shi bayan yashi ya busa.

2. Domin:

1) Tsarin simintin gyare-gyaren ba shi da ma'ana, kuma wuraren zafi suna da yawa ko girma

2) Ƙaƙƙarfan zafi na hawan hawan mai ƙarami ne, wanda ya kasa samar da ƙarfafawar tsari, ko kuma matsin kai karami ne, wanda ke rage karfin ciyarwa.

3) Yanayin zafin jiki yana da ƙasa, yawan sanyaya yana da sauri, kuma an katange tashar ciyarwa

3. Matakan rigakafi:

1) Inganta tsarin simintin gyare-gyare da rage zafi

2) Sanya mai tashi da kyau, ko ƙara haƙarƙarin ciyarwa wanda za'a iya cirewa ta hanyoyin sarrafawa, ƙara matsi mai kai, ta yaddazuba jari simintin gyaran kafaza a iya ƙarfafawa bi da bi a ƙarƙashin aikin wani matsi na kai

3) Daidaita ƙara yawan zafin jiki da zafin jiki don rage yawan sanyaya

Tsatsa mai zafi

1. Bayanin matsala:

Ana samar da tsagewar tsaka-tsakin tsaka-tsaki a saman ko ciki, kuma saman yana oxidized. Ana iya ganin shi bayan tsaftacewar yashi mai tsanani, kuma kawai ana iya samun aiki mai sauƙi ko dubawar shiga.

2. Dalilai:

1) Yana da alaƙa da abun da ke ciki na gami, abun ciki na carbon da silicon yana da girma, yawan zafin jiki na lokaci mai ƙarfi na ruwa yana da girma, kuma fashewar zafi yana da sauƙi.

2) Low m zafin jiki, matalauta retreatability da sauri sanyaya kudi

3) Kauri na simintin gyare-gyare ya bambanta sosai, kuma fillet ɗin miƙa mulki ya yi ƙanƙanta

3. Matakan rigakafi:

1) Don gami ko karafa waɗanda ke da saurin fashewar zafi, yakamata a sarrafa abun ciki na carbon da silicon gwargwadon yuwuwar zuwa matsakaici da ƙananan iyaka.

2) Ƙara yawan zafin jiki yayin zubarwa, rage yawan sanyin simintin, ko rage ƙarfin harsashi.

3) Ƙara haƙarƙari na hana fasawa a mahaɗin kauri na simintin gyare-gyare, ko ƙara fillet ɗin miƙa mulki.

Ciwon sanyi

Suna da Halaye:

Akwai tsage-tsafe masu ci gaba da shiga kan simintin. Wani wuri mai sheki ko kuma wani fili mai oxidized yana bayyana a karyewar.

Dalilai

1. A lokacin aikin sanyaya na simintin gyare-gyare, raguwa yana hanawa, yana haifar da matsananciyar zafi da canjin lokaci, kuma waɗannan matsalolin sun wuce ƙarfin kayan aiki a cikin yanayi na roba kuma suna haifar da karaya.

2. A cikin aiwatar da tsaftace harsashi, yankan kofa, hawan ko lokacin daidaitawa, simintin gyare-gyare tare da saura danniya yana fuskantar karfi na waje don haifar da karaya.

Hanyoyin Rigakafi

1. Ƙara haƙarƙari masu taurin kai a cikin faɗuwar sanyi don haɓaka dawo da sifar, ta haka rage juriya da zubar da damuwa.

2. A cikin aikin bayan simintin, guje wa tasiri mai tsanani tsakanin simintin.

Bututun iska

Suna da Halaye

Akwai ramuka na fili ko maras ganewa tare da santsin saman ciki akan simintin.

Dalilai

1. Rashin ƙarancin iska na harsashi, wanda ke sa ya yi latti don fitar da iskar gas a cikin rami yayin zubarwa.

2. Rashin isassun harbe-harbe na siffar harsashi, yana haifar da rashin isassun cire ragowar kayan ƙira da kayan samar da iskar gas a cikin kayan harsashi.

3. Abubuwan da ke cikin ruwa na ƙarfe na ruwa ya yi yawa, yana haifar da ƙarancin deoxidation.

4. Saitin tsarin zubar da ruwa ba shi da ma'ana, yana haifar da iskar gas na ɗan adam a cikin zubar.

Hanyoyin Rigakafi

1. Haɓaka haɓakar iska na harsashi kuma ƙara haɓakawa idan ya cancanta.

2. Cikakken harsashi.

3. Inganta hanyoyin deoxidation.

4. Inganta tsarin gating.

Yin Fitowa

Suna da Halaye

Akwai ramuka masu yawa kamar dige-dige a saman simintin.

Dalilai

1. Lokacin da aka yi amfani da ethyl silicate a matsayin mai ɗaure, rashin cika hydrolyzate yana cikin tsarin sutura, yanayin dangi na cikin gida ya yi ƙasa sosai, don haka hydrolyzate ba za a iya ƙara ruwa ba, kuma "farin sanyi" yana tasowa bayan gasa.

2. Lokacin da aka yi amfani da gilashin ruwa a matsayin mai ɗaure, ragowar gishirin da ke cikin kwandon ƙura yana amsawa da narkakken ƙarfe don samar da rami.

3. Karfe da aka narkar da shi ba shi da kyau a cire shi ko kuma ba a tsaftace slag yayin bugawa.

Hanyoyin Rigakafi:

1. Lokacin amfani da ethyl silicate a matsayin mai ɗaure, da kyau ƙara yawan adadin ruwan da aka ƙara da kuma ƙara ƙarancin dangi na ɗakin fenti don rage ragowar ƙarancin hydrolysates.

2. Lokacin amfani da gilashin ruwa a matsayin mai ɗaure, tsaftace harsashi da ruwa mai acidified bayan dewaxing.

3. Canja murfin saman zuwa silica sol azaman mai ɗaure.

4. A lokacin smelting, ƙarfafa deoxidation da kuma cire slag.

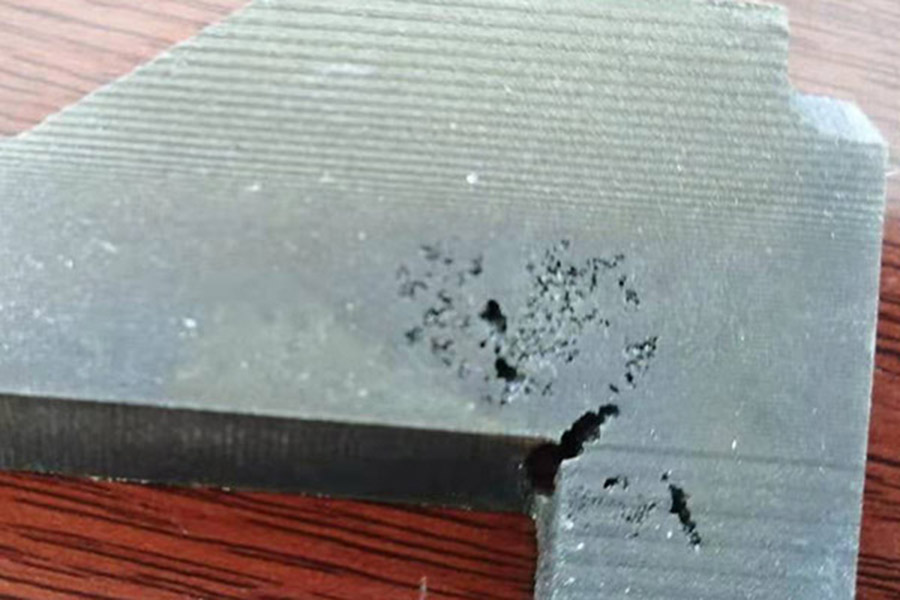

Jefa subcutaneus filhole

Suna da Halaye

Bayan an goge saman simintin, ƙananan baƙaƙen tabo suna bayyana. Wannan al'amari galibi yana faruwa ne a cikinickel-chromium bakin steel.

Dalilai:

1. Ana amfani da kayan da aka sake yin fa'ida da yawa yayin narkakkar karfe, ko kuma kayan da aka sake sarrafa ba a kula dasu yadda ya kamata ba.

2. A lokacin aikin narkewar, ƙarfen da aka narkar da shi ya zama oxidized ko narkakken ƙarfe yana sha iskar gas, yana haifar da rashin isassun deoxidation.

3. Abubuwan da ke cikin ƙazanta na kayan harsashi sun yi yawa, ko kuma wakilin haɗin gwiwa da narkakken ƙarfe suna da halayen sinadarai.4. Saitin tsarin gating mara ma'ana.

Hanyoyin Rigakafi:

1. Sarrafa ko rage adadin kayan da aka sake fa'ida, kuma ana buƙatar amfani da kayan da aka sake fa'ida bayan busa yashi ko harbe-harbe.

2. Tsananin sarrafa tsarin narkewa da ƙarfafa deoxidation.

3. Yi amfani da fused corundum, yashi zircon da silica sol ko ethyl silicate fenti.

4. Yi ƙoƙarin yin amfani da hanyar allura ta ƙasa don zubowa da haɓaka ramukan iska.

Sandy Sand

Suna da Halaye

Akwai yashi mai danko kusa da mai gudu ko a cikin simintin, kuma akwai buraguzai ko ramuka bayan yashi ya busa.

Dalilai

1. Abubuwan da ke cikin ƙazanta na foda refractory da aka yi amfani da su a cikin rufin saman rufin ya yi tsayi da yawa, kuma waɗannan ƙazantattun suna amsawa tare da narkakkar ƙarfe don samar da ƙananan narkewar eutectic.

2. Yawan zafin da ake zubawa ya yi yawa, musamman makin karfen da ke dauke da Al, Ti da sauran abubuwa, wanda ke haifar da dauki tsakanin narkakkar karfe da silica.

3. Saitin tsarin gating ba shi da ma'ana, kuma babban adadin narkakken ƙarfe yana gudana ta cikin mai gudu na ciki, yana haifar da zafi na gida.

Hanyoyin Rigakafi

1. Yi amfani da yashi mai gauraya na karfe ko yashi zircon maimakon yashi silica, kuma a yi ƙoƙarin kada a yi amfani da gilashin ruwa azaman ɗaure.

2. Dace da rage yawan zafin jiki na zuba.

3. Ƙara mai gudu na ciki don daidaita ma'aunin zafi da rage zafi na gida.

Dilatant

Suna da Halaye

Kumburi na gida a kan babban jirgin sama na simintin gyare-gyare, wannan al'amari ya fi bayyana yayin amfani da gilashin ruwa azaman ɗaure.

Dalilai

1. Tsarin simintin gyare-gyare ba shi da ma'ana kuma yankin jirgin yana da girma sosai.

2. Harsashi yana da ƙananan ƙarfi a babban zafin jiki kuma ba zai iya jurewa da matsa lamba na narkakkar karfe ba.

Hanyoyin Rigakafi

1. Inganta tsarin, ƙara haƙarƙarin tsari ko aiwatar da ramuka akan jirgin sama.

2. Lokacin yin harsashi, yi amfani da kayan harsashi tare da ƙarancin ƙazanta da rashin ƙarfi mai ƙarfi, ko ƙara kauri na harsashi.

Slag

Suna da Halaye

Akwai tarkace ko wasu tarkace a ciki ko saman simintin. Ana buƙatar gano abubuwan ciki ta hanyar X-ray ko duban maganadisu.

Dalilai

1. Kayan slag yana da bakin ciki sosai kuma ba a tsaftace shi ba kafin bugawa.

2. Ba a tsaftace tarkacen da ke cikin kwandon kwandon shara ba kafin a buga shi kuma an kawo shi cikin narkakkar karfen.

3. Lokacin simintin gyare-gyare, riƙewar shinge ba ta da kyau, kuma slag yana shiga cikin rami tare da narkakken karfe.

Hanyoyin Rigakafi

1. Daidaita abun da ke ciki na kayan aikin slag kafin yin amfani da shi don ƙara yawan danko na kayan ƙera kuma ya sa ya fi sauƙi don cire slag.

2. Tsaftace tarkacen da ke gaban kwandon karfen don guje wa kawo najasa a cikin narkakkar da ke cikin ledar.

3. Kafin yin simintin, narkakkarzufaya kamata a kwantar da hankali da kyau don sauƙaƙan tudu da ke iyo.

4. Ɗauki tukunyar shayin da ke zubo ladle tare da maƙarƙashiya ko tace yumbu.

Decarburization

Suna da halaye

Abubuwan da ke cikin carbon ɗin saman simintin simintin ya yi ƙasa da na matrix.

Dalilai

1. Yayin da ake yin simintin gyare-gyare, zafin narkakkar karfen da gyaggyarawa yana da girma, kuma ƙarfin ƙarfafawar simintin yana jinkirin.

2. Zurfin decarburization Layer yana da alaƙa da yanayin yanayin sanyaya na simintin gyaran kafa. Mafi girma da maida hankali na oxidizing yanayi, mafi tsanani da decarburization.

Hanyoyin Rigakafi

1. Daidaita rage zafin simintin simintin gyare-gyare da zazzabi mai ƙima don saurin yawan sanyaya.

2. Ƙirƙirar yanayi ta wucin gadi a kusa da mold, kamar ƙara barium carbonate da garwashi foda zuwa mold.

Lokacin aikawa: Janairu-22-2021