Ragewar simintin gyare-gyare abu ne mai mahimmanci wanda ke tasiri sosai ga inganci da amincin samfurin ƙarshe. Fahimtar nau'ikan raguwa daban-daban da ke tattare da abubuwa daban-daban, kamar jefa karfekumajefa baƙin ƙarfe, da kuma abubuwan da ke ba da gudummawa ga lahani kamar raƙuman raguwa da tsagewar zafi, suna da mahimmanci don ingantattun ayyukan simintin gyaran kafa.

Ƙarƙashin Ƙarfe da Ƙarfe na Cast

Lokacin magana akan raguwa, yana da mahimmanci don bambance tsakanin kayan farko guda biyu da aka yi amfani da su wajen yin simintin gyaran kafa:jefa karfekumajefa baƙin ƙarfe. Dukansu kayan suna nuna raguwa, amma hanyoyin da rates na iya bambanta.

Karfe na simintin gyare-gyare yawanci yana fuskantar jimlar raguwar kusan1.5% zuwa 2%daga narkakkarsa zuwa ga kaffaru. Wannan raguwa da farko shine saboda ƙarancin zafi na kayan yayin da yake sanyi. Sabanin haka, simintin ƙarfe yana da ƙimar raguwa mafi girma, gabaɗaya a kusa2% zuwa 3%. Ƙarin raguwa a cikin simintin ƙarfe za a iya danganta shi da abun da ke ciki, wanda ya haɗa da babban abun ciki na carbon wanda ke shafar halayen ƙarfafawa.

Haƙiƙanin Ragewar Castings

Haƙiƙanin raguwa yana nufin jimlar canjin girma da aka samu ta hanyar simintin gyare-gyare daga yanayin ruwan sa zuwa ƙarfinsa na ƙarshe. Wannan na iya haɗawa da raguwar volumetric yayin sanyaya da tasirin ƙarfafawa. Kyakkyawan ƙira da ƙididdige lissafin simintin simintin gyare-gyare suna da mahimmanci don ɗaukar wannan raguwar, saboda rashin yin hakan na iya haifar da rashin daidaitattun ƙira da ƙayyadaddun kayan aikin injiniya.

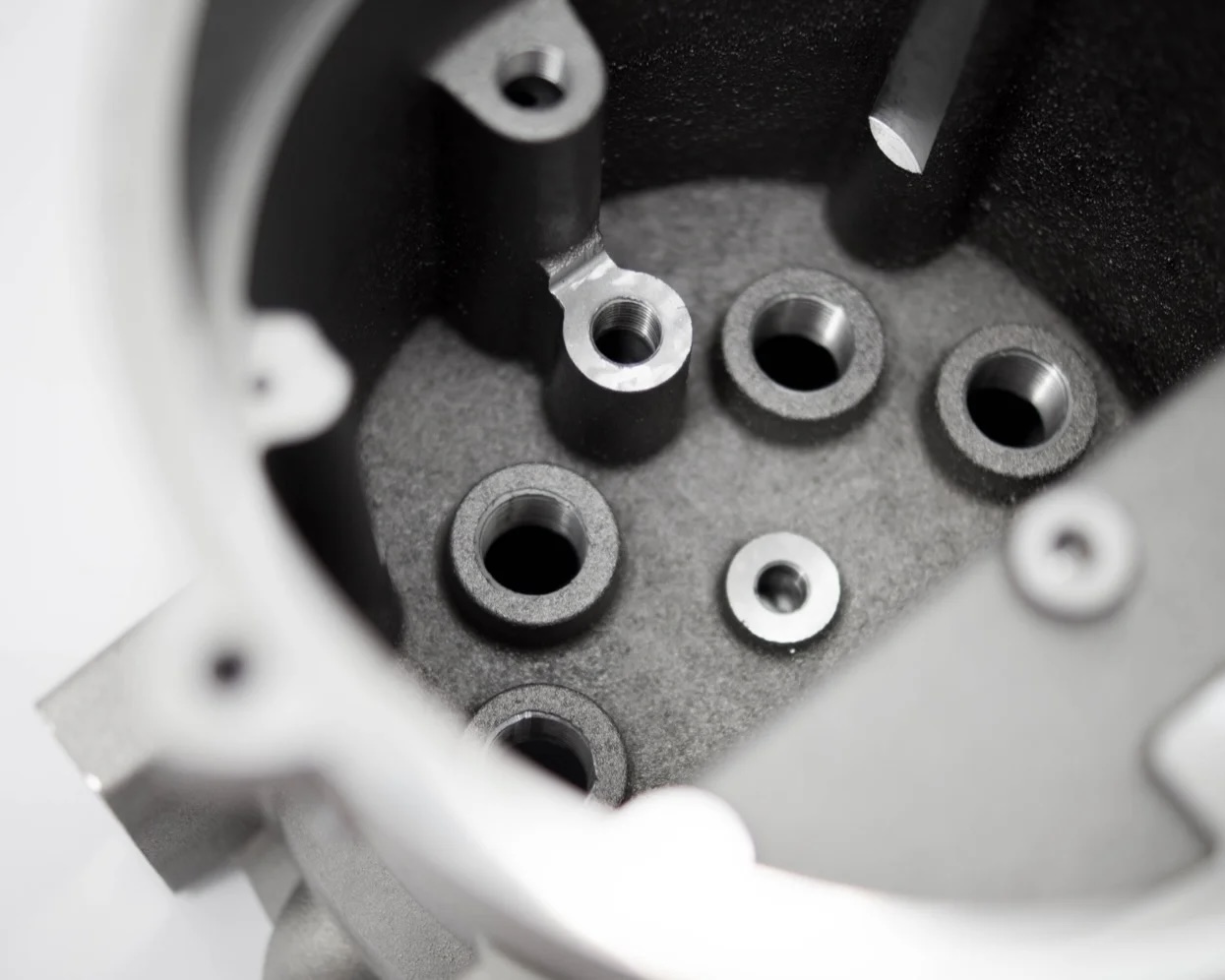

Ƙunƙarar Kogo da Ƙira

Ƙunƙarar ƙura, wanda kuma aka sani da ɓoyayyen ɓoyayyiya, yana faruwa lokacin da ƙarfen ruwa ya kasa cika ƙura saboda rashin isasshen ciyarwa yayin ƙarfafawa. Wannan al'amari na iya haifar da raunin rauni a cikin simintin gyare-gyare, yana sa ya zama mai sauƙi ga gazawa a ƙarƙashin kaya. A daya hannun, porosity-sau da yawa ana gani a cikin simintin gyare-gyare-yana faruwa da farko ta hanyar kama gas ko dabarar zubewar da ba ta dace ba, wanda zai iya ƙara rage amincin tsarin.

Zafafan Cracking da Matsalolin Cast

Zafafan tsagewa wani muhimmin damuwa ne a cikin simintin gyare-gyare. Waɗannan suna faruwa lokacin da har yanzu simintin gyare-gyaren yana kan matsanancin zafi amma ya fara ƙarfafawa. Matsalolin da aka haifar yayin sanyaya na iya wuce ƙarfin juzu'in kayan, yana haifar da karaya. Sarrafa adadin sanyaya da fahimtar yanayin zafi na kayan zai iya taimakawa rage haɗarin fashewar zafi.

Cracking Cold and Deformation

Fashewar sanyi yana faruwa bayan simintin ya yi sanyi zuwa ɗaki kuma yawanci sakamakon damuwa ne. Waɗannan matsalolin na iya tasowa daga rashin daidaituwar sanyaya, wanda ke haifar da bambance-bambance a cikin simintin gyaran kafa. Irin waɗannan matsalolin kuma na iya haifar da nakasu, suna yin tasiri ga siffa ta ƙarshe da kuma amfani.

Don rage yuwuwar fashewar sanyi da lalacewa, yana da mahimmanci don aiwatar da ingantattun dabarun sanyaya da hanyoyin magance damuwa yayin da bayan aikin simintin.

Lokacin aikawa: Oktoba-25-2024