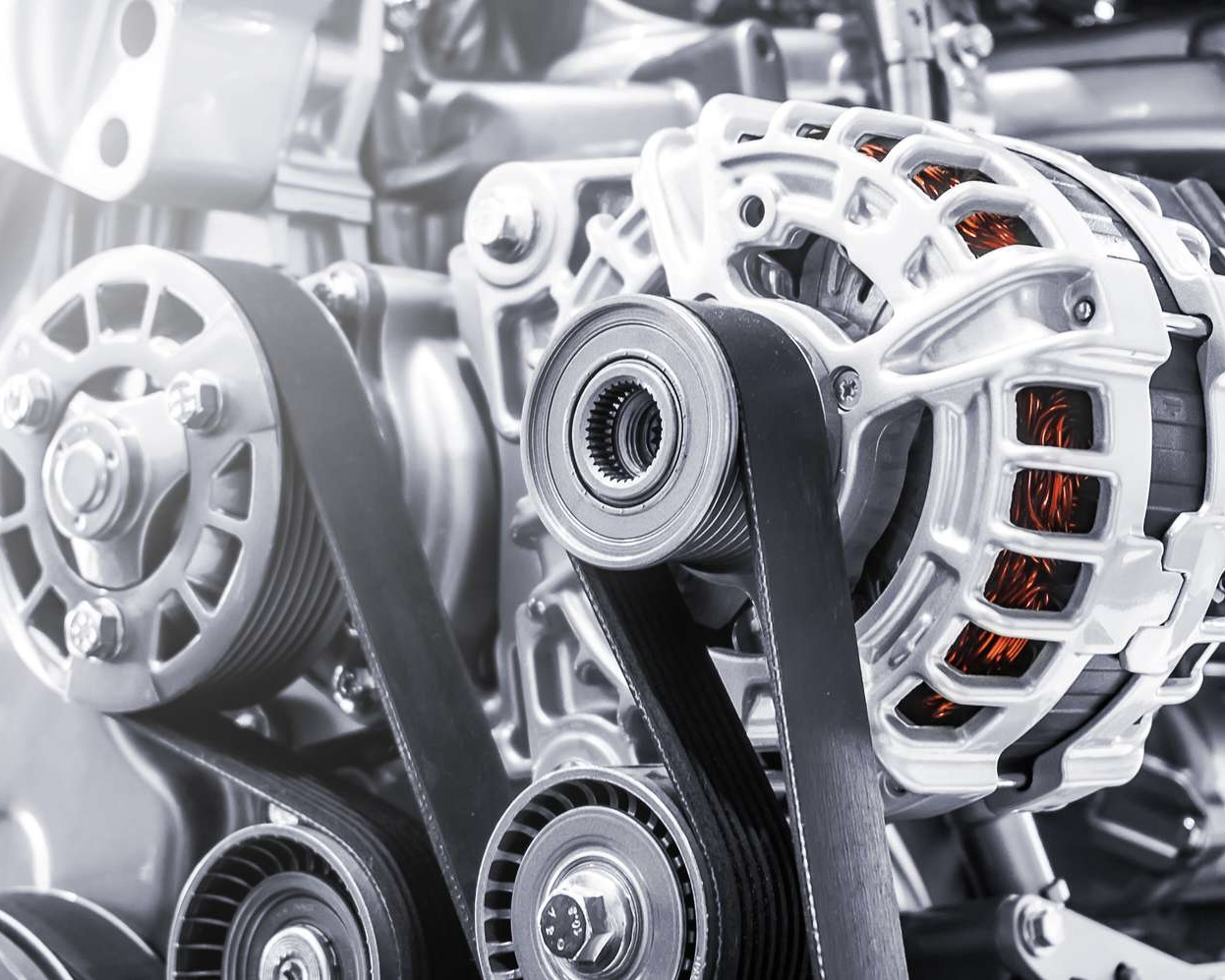

Hanyoyi masu ƙarfi

A lokacin aikin simintin gyare-gyare, ƙarfafawar simintin gyare-gyare yana faruwa lokacin da narkakken ƙarfe ya canza daga ruwa zuwa ƙaƙƙarfan yanayi. Ana iya rarraba wannan tsari gabaɗaya zuwa hanyoyi uku:nucleation, dendritic girma, kumahatsi tsarin samuwar. A lokacin nucleation, ƙananan ƙaƙƙarfan barbashi suna samuwa a cikin ƙarfen ruwa. Waɗannan nuclei suna girma zuwa tsarin dendritic, suna reshe a cikin tsari irin na bishiya. Tsarin hatsi na ƙarshe nasimintin gyare-gyareAn ƙaddara ta hanyar haɓakar waɗannan dendrites da hulɗar su tare da yanayin sanyi.

Ƙarfafan Alloys Daban-daban

Alloys daban-daban suna ƙarfafa ta hanyoyi na musamman, tasirin sinadaransu da kaddarorin thermal:

Aluminum Alloys: Aluminum alloys yawanci suna nuna yawan ruwa mai yawa, suna ba da damar yin simintin simintin gyare-gyare da bakin ciki. Ƙarfafa su sau da yawa ya haɗa da samar da tsari mai kyau, daidaitaccen tsarin hatsi. Duk da haka, aluminium alloys suna da haɗari ga raguwar porosity da zafi mai zafi, wanda zai iya rinjayar ingancin simintin.

Iron daKarfe Alloys: Ƙarfe na simintin gyare-gyare yana ƙarfafawa tare da tsari mai rikitarwa saboda yawan abun ciki na carbon, yana samar da flakes graphite ko nodules. Ƙarfafawar kayan ƙarfe na ƙarfe ya ƙunshi samuwar austenite dendrites, wanda ke canzawa zuwa ferrite da pearlite akan sanyaya. Adadin sanyaya da abun da ke ciki na gami yana tasiri sosai akan tsarin hatsi da kaddarorin inji na simintin gyaran kafa.

Garin Copper: Alloys na Copper, irin su tagulla da tagulla, suna ƙarfafawa tare da ginshiƙi ko tsarin hatsi daidai. Wadannan allunan suna da wuyar rarrabuwa, inda abubuwa daban-daban a cikin gami suka rabu yayin ƙarfafawa, suna haifar da bambance-bambance a cikin abun da ke ciki da kaddarorin a cikin simintin.

Dangantaka Tsakanin Ƙarfafawa da Ingantacciyar Cast

Halayen ƙarfafa haɗin gwiwa yana tasiri kai tsaye ingancin simintin. Tsarin daidaitawa na uniform da sarrafawa yana da mahimmanci don rage lahani kamar porosity, rarrabuwa, da tsagewar zafi. Misali, saurin sanyaya na iya haifar da samuwar hatsi masu kyau, haɓaka kayan aikin simintin gyaran kafa. Sabanin haka, jinkirin sanyaya na iya haifar da ƙananan hatsi da kuma ƙara saurin lahani.

Lokacin Ƙarfafawa da Gudu

Lokacin ƙarfafawa da saurin abubuwa kamar girman simintin gyare-gyare, siffa, da kaddarorin zafi na kayan ƙira suna tasiri. Lokacin ƙarfafawa shine tsawon lokacin da ake buƙata don ɗaukacin simintin gyare-gyare don canzawa daga ruwa zuwa ƙarfi, yayin da ƙaƙƙarfan saurin yana nufin ƙimar da wannan canji ke faruwa.

Ana samun saurin ƙarfafa ƙarfi gabaɗaya ta hanyar dabaru kamar yin amfani da gyare-gyare masu sanyi, waɗanda ke fitar da zafi cikin sauri daga narkakken ƙarfe. Wannan yana haifar da mafi kyawun tsarin hatsi da ingantattun kayan aikin injiniya. Koyaya, sanyaya da sauri fiye da kima na iya haifar da matsalolin zafi da fashewa. Don haka, samun daidaiton ma'auni tsakanin saurin ƙarfafawa da ingancin simintin gyare-gyare yana da mahimmanci.

Lokacin aikawa: Oktoba-11-2024