Baƙin ƙarfe, wanda yafi rufe baƙin ƙarfe simintin toka, baƙin ƙarfe simintin gyare-gyare, simintin gyare-gyaren ƙarfe da sauran ƙarfen simintin ƙarfe, ana amfani da shi sosai.RMC Casting Foundry. Simintin gyare-gyare na simintin gyare-gyare na taka muhimmiyar rawa a cikimasana'antu na zamani. Don zaɓar matakan da suka dace kuma masu dacewa na simintin simintin gyare-gyare da ƙarfe na simintin ƙarfe zai taimaka muku don samun simintin ƙarfe a ƙaramin farashi da ɗan gajeren lokacin jagora.

Anan a cikin masu zuwa muna ba da shawarar wasu ƙa'idodi ko dalilai lokacin da muka zaɓamatakan simintin gyaran kafa masu dacewadon simintin ƙarfe kayan. Gabaɗaya magana, tsarin simintin ƙarfe da aka fi amfani da shi shine simintin yashi, sannan kuma hanyoyin yin simintin na musamman, kamar simintin gyare-gyaren ƙarfe, simintin saka hannun jari, gyare-gyaren harsashi,rasa kumfada vacuum simintin.

1- Yashi Ya kamata Ya zama Zabi Na Farko

Yafi saboda low cost da sauki samar datsarin simintin yashi, simintin yashi ya ɗauki kusan kashi 60% zuwa 70% na jimillar samar da simintin, kuma kusan kashi 70% na simintin yashi koren yashi ne. Lokacin da koren yashi ba zai iya biyan buƙatun ba sannan zaka iya la'akari da amfani da yashi bushe ko sauran yashi. Matsakaicin simintin yashi kore daga kilogiram da yawa zuwa ɗaruruwan kilogiram, yayin da samar da busasshen simintin yumbu zai iya auna ton da yawa.

Tsarin simintin yashi yana amfani da nau'ikan yashi don yin simintin gyare-gyare. Hakanan za'a iya raba shi zuwa nau'i uku:

1) Green Sand Casting, wanda ke amfani da yashi (kore) yashi don samar da mold.

2) Guduro Mai Rufaffen Yashida No-Bake Sand Mold Simintin gyaran kafa (Taurin Gurorin Yashi na Kai), wanda ke amfani da kayan haɗin kai don taimakawa wajen samar da tsarin gyare-gyare.

3) Dry Sand Casting, wanda galibi yana amfani da busassun ba tare da kayan sinadarai ba don yin gyare-gyare. Tsarin simintin yashi busasshen yana nufin ɓataccen simintin kumfa dainjin motsa jiki.

Gabaɗaya magana, don matsakaici da manyan simintin ƙarfe, simintin yashin guduro mai ƙarfi zai zama zaɓi mai kyau. Amma game da gami karfe da carbon karfe kayan, za mu iya zabar ruwa gilashin yashi. Wannan na iya samun ingantattun ma'auni, santsin saman simintin, yayin da tare da ƙarancin farashi fiye da tsarin simintin saka hannun jari na silica sol.

Daidaitacce, ƙarewar ƙasa, ƙarancin kayan abu da microstructure, kaddarorin injiniyoyi na iya ba za su iya isa ga ƙaƙƙarfan requrieemenets ba idan kuna da buri na musamman da kuma babban tsammanin. A wannan yanayin, wasu hanyoyin yin simintin simintin gyare-gyare kamar simintin sol ko simintin saka hannun jari na gilashin ruwa, jefarwar mutuwa, simintin ƙarancin matsa lamba, ɓataccen simintin kumfa da zubar da ruwa ya kamata a ɗauka cikin idanunmu.

2- Tunani Akan Bukatun Shekara

Idan buƙatar ku na shekara-shekara yana da girma, layin gyare-gyaren atomatik ya kamata ya zama mafi kyawun zaɓi saboda babban ƙarfinsa na samarwa da tsayin daka. Kuma wannan hanya na iya kaiwa matsakaicin matsakaicin farashi kawai idan adadin da ake buƙata ya isa sosai. Yayin, yin gyare-gyare da hannu zai adana kuɗin ku idan adadin ku bai yi girma ba, ko kuma simintin gyare-gyaren da kuke so matsakaita ne ko babba.

Koyaya, tsarin simintin simintin yashin guduro (ƙwanƙwasa harsashi) shima ya dace da simintin ƙarfe mai girma. Bugu da ƙari, simintin gyare-gyaren harsashi yana da mafi kyawun ƙarewa da inganci mafi girma sannan koren yashi.

Sauran matakai irin su ƙananan matsa lamba sun mutu simintin gyare-gyaren gyare-gyaren gyare-gyaren gyare-gyaren gyare-gyaren gyare-gyaren gyare-gyaren gyare-gyaren gyare-gyare, gyare-gyaren gyare-gyare, centrifugal simintin gyare-gyare ya dace kawai don samar da taro tare da adadi mai yawa saboda kayan aiki masu tsada da kayan aiki.

3- Hakuri Mai Girma da Ƙididdigar Ingantattun Fashi

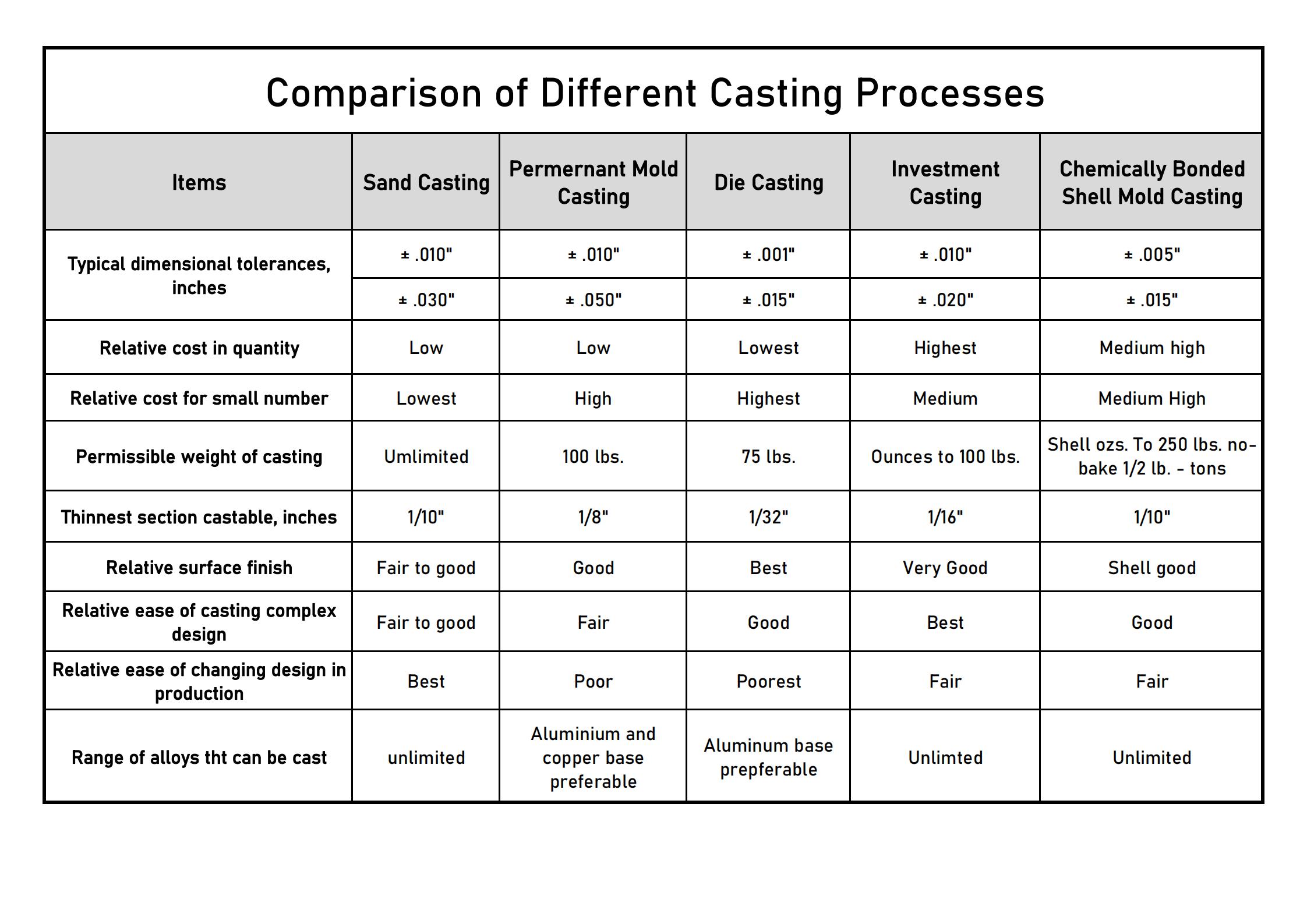

A yayin zabar tsarin simintin simintin gyare-gyare na simintin ƙarfe na simintin ƙarfe, daidaiton girma da ingancin saman suma suna da mahimmanci. Zabar adaidaitaccen tsarin simintin gyare-gyarezai rage buƙatar injina, ko da ba tare da injina ba. Wannan yana buƙatar cikakken la'akari da ma'auni tsakanin haɓakar farashin simintin gyare-gyare da raguwar mashin ɗin. Dangane da gogewar da muka yi na shekaru masu yawa, injiniyoyin kamfaninmu na iya zabar muku mafi dacewa da tsarin simintin arziƙi.

Lokacin aikawa: Janairu-28-2021