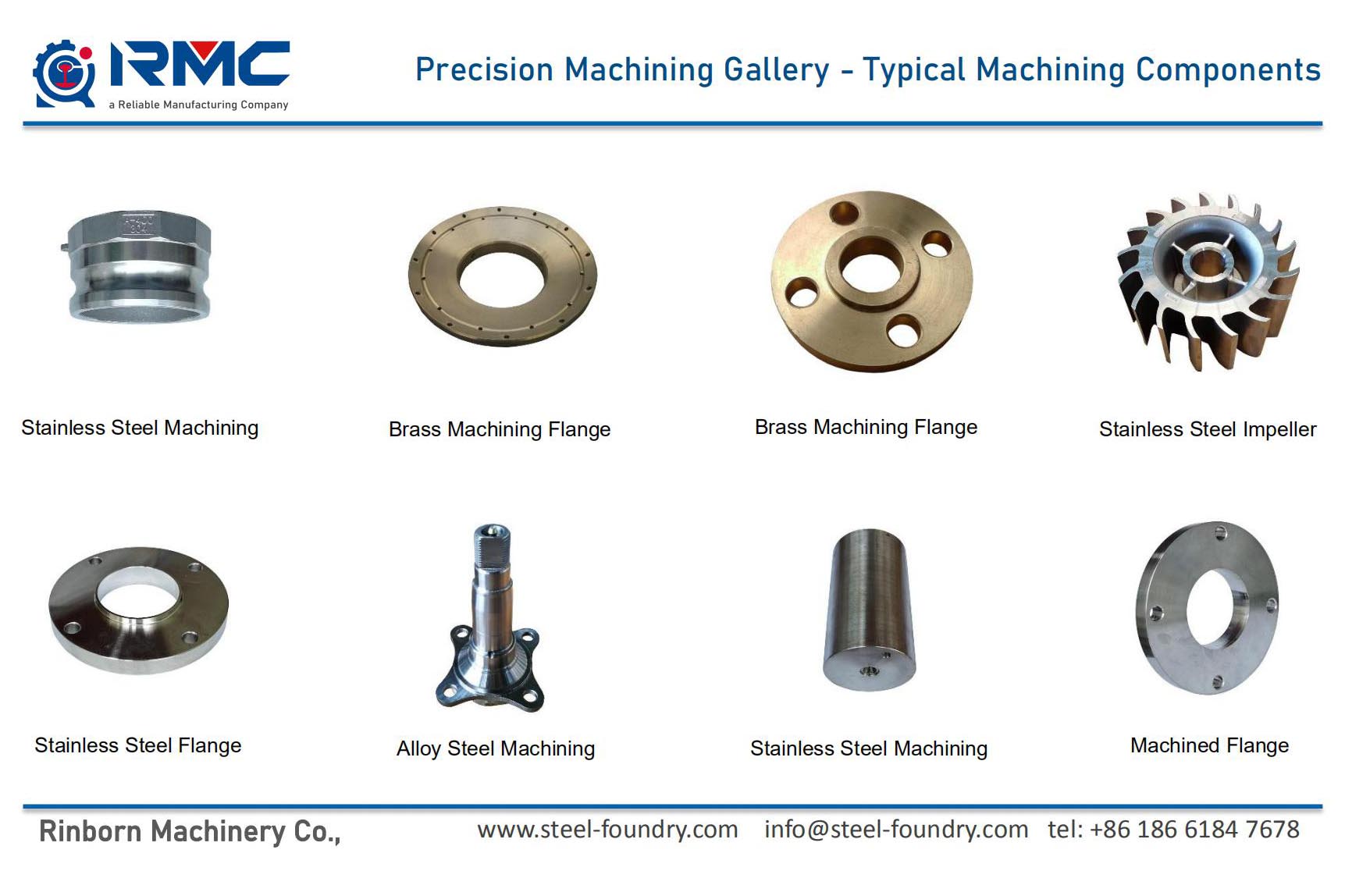

China OEM al'ada tagulla CNC machined flange ta rasa kakin zuma zuba jari simintin gyaran kafa, zafi magani da surface jiyya kamar yadda ta your zane da kuma musamman bukatun.

Injin CNCYana nufin tsarin aikin injin da aka ci gaba ta hanyar Gudanar da Lamba na Computer (CNC a takaice). CNC na taimaka masa don isa ga daidaito mai tsayi tare da ƙarancin farashin aiki. Machining wani nau'i ne na matakai daban-daban wanda aka yanke wani yanki na albarkatun kasa zuwa siffar karshe da ake so ta hanyar sarrafa kayan cirewa. Hanyoyin da ke da wannan jigo na gama gari, cire kayan sarrafawa, a yau an san su gaba ɗaya da masana'antu masu rahusa, a bambanta daga hanyoyin haɓaka kayan sarrafawa, waɗanda aka sani da masana'anta ƙari.

Daidai abin da ɓangaren "sarrafawa" na ma'anar zai iya bambanta, amma kusan koyaushe yana nuna amfani da kayan aikin inji (ban da kawai kayan aikin wuta da kayan aikin hannu). Wannan tsari ne da ake amfani da shi don kera da yawakarfe inji kayayyakin, amma kuma ana iya amfani dashi akan kayan kamar itace, robobi, yumbu, da kuma abubuwan da aka haɗa. Kayan aikin CNC ya ƙunshi matakai daban-daban kamar niƙa, juyawa, lathing, hakowa, honing, niƙa ... da sauransu.

Brass nasa negami da jan karfekuma wani gami ne wanda ya hada da jan karfe da zinc. Brass wanda ya hada da jan karfe da zinc ana kiransa tagulla na yau da kullun. Idan nau'in allo ne da ya ƙunshi abubuwa sama da biyu, ana kiransa tagulla na musamman. Brass shine gami da jan ƙarfe tare da zinc a matsayin babban kashi. Yayin da abun ciki na zinc ya karu, ƙarfin da filastik na gami yana ƙaruwa sosai, amma kayan aikin injiniya za su ragu sosai bayan wuce 47%, don haka abun ciki na zinc na tagulla yana ƙasa da 47%. Baya ga zinc, tagulla na simintin sau da yawa yana ƙunshe da abubuwa masu haɗawa kamar silicon, manganese, aluminum, da gubar.

| CNC Daidaitaccen Machining Capabilities | ||||

| Kayayyakin aiki | Yawan | Girman Rage | Ƙarfin shekara | Daidaito Gabaɗaya |

| Cibiyar Injin Injiniya (VMC) | 48 sets | 1500mm × 1000mm × 800mm | ton 6000 ko guda 300000 | ± 0.005 |

| Horizontal Machining Center (VMC) | 12 sets | 1200mm × 800mm × 600mm | Ton 2000 ko guda 100000 | ± 0.005 |

| Injin CNC | 60 sets | Mafi girman juyawa. φ600mm | Ton 5000 ko guda 600000 | |

| Matsakaicin Haƙuri na Casting: ISO 8062 2013, ISO 2768, GOST 26645 (Rasha) ko GBT 6414 (China). | ||||

An haɓaka cibiyar mashin ɗin daga injin niƙa na CNC. Babban bambanci daga injin milling na CNC shine cewa cibiyar mashin ɗin tana da ikon musayar kayan aikin injin ta atomatik. Ta hanyar shigar da kayan aiki don dalilai daban-daban akan mujallar kayan aiki, ana iya canza kayan aikin injin a kan sandal ta atomatik mai canza kayan aiki a cikin ƙwanƙwasa ɗaya don gane fasalin mashin ɗin da yawa.

Cibiyar mashin din CNC ita ce kayan aiki mai inganci mai inganci wanda ke kunshe da kayan aikin injiniya da tsarin CNC kuma ya dace da sarrafa sassa masu rikitarwa. Cibiyar injina ta CNC a halin yanzu tana ɗaya daga cikin kayan aikin injin CNC da aka fi amfani da shi a duniya tare da ingantaccen ikon sarrafawa. Yana iya kammala ƙarin aiki abun ciki bayan da workpiece da aka clamped a lokaci guda. Daidaiton sarrafawa yana da girma. Don batch workpieces tare da matsakaicin matsakaicin aiki, ingancin sa shine sau 5-10 na kayan aiki na yau da kullun, musamman yana iya kammala yawancin sarrafawa waɗanda ba za a iya kammala su ta hanyar kayan aiki na yau da kullun ba sun fi dacewa da aiki guda ɗaya tare da ƙarin hadaddun siffofi da madaidaicin buƙatun ko domin kanana da matsakaita samar da iri iri-iri. Yana mai da hankali kan ayyukan niƙa, ban sha'awa, hakowa, bugun zare da yanke zaren akan na'ura ɗaya, ta yadda za ta sami hanyoyin fasaha iri-iri.

| Kwatancen Daraja na Copper, Brass da Bronze | |||||||

| KURUNIYA | AISI | W-tafi | DIN | BS | JIS | EN | ISO |

| KWANA | C10200 | 2.0040 | KU | C103 | C1020 | CW008A | Ku-OF |

| C11000 | 2.0060 | E-Cu57 | C101 | C1100 | CW004A | Ku-ETP | |

| - | 2.0065 | E-Cu58 | - | - | - | - | |

| C10300 | 2.0070 | SE Ku | - | - | CW021A | - | |

| C12200 | 2.0090 | SF Ku | C106 | C1220 | CW024A | Ku-DHP | |

| C12500 | - | Ku-FRTP | C104 | - | CR006A | - | |

| C70320 | 2.0857 | - | - | - | Saukewa: CW112C | KuNi3Si | |

| C14200 | 2.1202 | SB Ku | C107 | - | - | Ku-AsP | |

| - | 2.1356 | Ku Mn 3 | - | - | - | - | |

| - | 2.1522 | Ku Si2 Mn | - | - | - | - | |

| C16200 | - | C108 | - | - | KuCd1 | ||

| C18200 | - | Saukewa: CC101 | - | Saukewa: CW105C | KuCr1 | ||

| C191010 | - | - | - | Saukewa: CW109C | KuNi1Si | ||

| C70250 | - | Saukewa: CC102 | - | Saukewa: CW111C | KuNi2Si | ||

| C17200 | - | Farashin CB101 | - | Saukewa: CW101C | KuBe2 | ||

| C17300 | - | - | - | Saukewa: CW102C | CuBe2Pb | ||

| C17510 | - | - | - | Saukewa: CW110C | CuNi2Be | ||

| C17500 | - | C112 | - | Saukewa: CW104C | KuCo2Be | ||

| C15000 | - | - | - | Saukewa: CW120C | KuZr | ||

| C65100 | - | - | - | CW115C | KuSi2Mn | ||

| C65500 | - | Saukewa: CS101 | - | CW116C | KuSi3Mn1 | ||

| C14500 | - | C109 | - | CW118C | CuTeP | ||

| C14700 | - | C111 | - | Saukewa: CW114C | KuSP | ||

| C18700 | - | - | - | CW113C | KuPb1P | ||

| BRASS | C21000 | 2.0220 | KuZn5 | CZ125 | C2100 | CW500L | - |

| C22000 | 2.0230 | KuZn10 | Cz101 | C2200 | Saukewa: CW501L | - | |

| C23000 | 2.0240 | KuZn15 | CZ102 | C2300 | Saukewa: CW502L | - | |

| C24000 | 2.0250 | KuZn20 | CZ103 | C2400 | Saukewa: CW503L | - | |

| C25600 | - | KuZn28 | - | - | - | - | |

| C26000 | 2.0265 | KuZn30 | CZ106 | C2600 | Saukewa: CW505L | - | |

| C26800 | 2.0280 | KuZn33 | - | C2680 | Saukewa: CW506L | - | |

| C27200 | - | KuZn36 | - | - | - | - | |

| C27200 | 2.0321 | KuZn37 | CZ108 | C2700 | Saukewa: CW508L | - | |

| C27000 | 2.0335 | KuZn36 | CZ107 | C2700 | Saukewa: CW507L | - | |

| C28000 | 2.0360 | KuZn40 | CZ109 | C2800 | Saukewa: CW509L | - | |

| C33500 | - | CuZn37Pb0.5 | - | - | - | - | |

| C34000 | - | Farashin 35Pb1 | CZ118 | C3501 | - | - | |

| C34500 | 2.0331 | KuZn36Pb1,5 | CZ119 | - | CW601N | - | |

| C34000 | 2.0331 | KuZn36Pb1,5 | CZ119 | C3501 | CW600N | - | |

| C35300 | 2.0371 | KuZn38Pb1,5 | CZ128 | - | - | - | |

| C36500 | 2.0372 | KuZn39Pb0,5 | CZ123 | - | CW610N | - | |

| C36000 | 2.0375 | KuZn36Pb3 | CZ124 | C3601 | Saukewa: CW603N | - | |

| C37700 | 2.0380 | Farashin 39Pb2 | CZ 131 / (CZ128) | C3771 | CW612N | - | |

| C38500 | 2.0401 | KuZn39Pb3 | CZ121 | C3603 | CW614N | - | |

| C38000 | 2.0402 | CuZn40Pb2 | CZ122 | - | CW617N | - | |

| - | 2.0410 | Farashin 44Pb2 | CZ130 | - | - | - | |

| C68700 | 2.0460 | CuZn20Al2 | CZ110 | - | - | - | |

| C44300 | 2.0470 | CuZn28Sn1 | CZ111 | - | - | - | |

| - | 2.0530 | KuZn38Sn1 | - | - | - | - | |

| - | 2.0550 | CuZn40Al2 | - | - | - | - | |

| - | 2.0561 | CuZn40Al1 | - | - | - | - | |

| - | 2.0572 | KuZn40Mn2 | CZ136 | - | Saukewa: CW723R | - | |

| C61400 | 2.0932 | KuAl8Fe3 | - | - | Saukewa: CW303G | - | |

| C63000 | 2.0966 | CuAl10Ni5Fe4 | CA104 | - | CW307G | - | |

| TAgulla | C50700 | 2.1010 | KuSn2 | - | - | - | - |

| C51100 | 2.1016 | KuSn4 | Saukewa: PB101 | C5111 | CW450K | - | |

| C51000 | - | KuSn5 | Saukewa: PB102 | C5102 | CW451K | - | |

| C51900 | 2.1020 | KuSn6 | Saukewa: PB103 | C5191 | CW452K | - | |

| C52100 | 2.1030 | KuSn8 | Saukewa: PB104 | C5212 | CW453K | - | |

| - | - | KuSn10 | - | - | - | - | |

| - | - | CUSn11 | - | - | - | - | |

| - | - | KuSn12 | - | - | - | - | |

An rarraba cibiyoyin injuna zuwa cibiyoyin injuna a kwance da na tsaye gwargwadon matsayinsu yayin aikin injinan sandar. Rarraba bisa ga tsarin amfani: m da milling machining center, fili machining center. Bisa ga rarrabuwa na musamman na ayyuka, akwai: guda workbench, biyu workbench da Multi-workbench machining cibiyar. Cibiyoyin machining tare da axis guda ɗaya, dual-axis, axis uku, axis huɗu, axis biyar da maɓalli masu musanyawa, da sauransu.

CNC machining shine nau'in mashin ɗin daidaitaccen mashin ɗin CNC kamar cibiyoyi masu haɓakawa waɗanda ke da babban ƙarshen 5 axis machining center, 4 axis sau biyu cibiyar machining, ko CNC juya lathes wanda kuma za'a iya haɓaka zuwa cibiyar juyawa ta CNC tana da ikon canza ƙarin ƙari. fiye da masu yankan 15 a cikin motsi guda ɗaya; CNC milling inji da CNC hakowa da tapping cibiyoyin. Daidaitaccen mashin ɗin aikin simintin ƙarfe ya bambanta da mashin ɗin bayanan ƙarfe. Daidaitaccen simintin gyare-gyare ya riga ya sami ainihin ainihin siffar abin da ake so, don haka yana adana ɗimbin machining idan aka kwatanta da machining daga bayanan karfe kai tsaye. Hakanan saboda wannan dalili, yawanci dole ne mu yi la'akari da kayan aikin injin da kuma izinin injin da ya dace kafin yin simintin. Sayen mu na yau da kullun shine aiwatar da zanen simintin gyare-gyare tare da zanen injina don tantance yankin injina da izinin injina akan zanen.

RMC zuba jari simintin kafa foundry ya sanye take da 4 axis machining cibiyoyin, 15 sets na CNC juya lathes da 3 sets na cnc milling inji, tare da mataimakin na kowa m juya, niƙa, tapping, hakowa da nika inji, muna da ikon machining kusan duk. nau'ikan simintin ƙarfe.

Hakanan ana kiran mashin daidaitaccen mashin ɗin, injinan CNC na iya kaiwa ga daidaito mai tsayi a juriyar jumhuriya da juriyar juzu'i. Tare da injunan mu na CNC da Cibiyoyin Machining Horizontal Machining (HMC) da Cibiyoyin Machining (VMC), kusan muna iya saduwa da duk makin haƙurin da kuke buƙata.

Abubuwan iyawa naZuba Jari Cemin Foundry:

• Girman Girma: 1,000 mm × 800 mm × 500 mm

• Nauyin Nauyi: 0.5 kg - 100 kg

• Yawan Shekara: ton 2,000

• Kayayyakin Lantarki don Gina Shell: Silica Sol, Gilashin Ruwa da haɗe-haɗensu.

Haƙuri: Akan Buƙatar.

AmfaninAbubuwan Simintin Zuba Jari:

- Madalla da m surface gama

- Haƙurin juzu'i masu ƙarfi.

- Siffa masu rikitarwa da rikitarwa tare da sassauƙar ƙira

- Ƙarfin jefa bangon bakin ciki don haka ɓangaren simintin gyare-gyare mai sauƙi

- Zaɓin zaɓi na ƙarfe na simintin ƙarfe da gami (na ƙarfe da mara ƙarfe)

- Ba a buƙatar daftarin aiki a cikin ƙirar ƙira.

- Rage buƙatar injiniyoyi na biyu.

- Low kayan sharar gida.

| HAKURI JIN JINI | |||

| Inci | Millimeters | ||

| Girma | Hakuri | Girma | Hakuri |

| Har zuwa 0,500 | ±.004" | Har zuwa 12.0 | ± 0.10mm |

| 0.500 zuwa 1.000" | ±.006" | 12.0 zuwa 25.0 | ± 0.15mm |

| 1.000 zuwa 1.500" | ±.008" | 25.0 zuwa 37.0 | ± 0.20mm |

| 1.500 zuwa 2.000" | ±.010" | 37.0 zuwa 50.0 | ± 0.25mm |

| 2.000 zuwa 2.500" | ±.012" | 50.0 zuwa 62.0 | ± 0.30mm |

| 2.500 zuwa 3.500" | ±.014" | 62.0 zuwa 87.0 | ± 0.35mm |

| 3.500 zuwa 5.000" | ±.017" | 87.0 zuwa 125.0 | ± 0.40mm |

| 5.000 zuwa 7.500" | ±.020" | 125.0 zuwa 190.0 | ± 0.50mm |

| 7.500 zuwa 10,000" | ±.022" | 190.0 zuwa 250.0 | ± 0.57mm |

| 10.000 zuwa 12.500" | ±.025" | 250.0 zuwa 312.0 | ± 0.60mm |

| 12.500 zuwa 15.000 | ±.028" | 312.0 zuwa 375.0 | ± 0.70mm |