A RMC Casting Foundry, mun yi amfani daguduro mai rufi yashi mold(babu tsarin gasa da taurin kai) don jefa tagulla, tagulla da sauran abubuwan gami da tagulla.

Simintin ƙarfeana amfani da su sosai a cikin bawul da filin famfo saboda kyakkyawan aiki na kayan tagulla. A RMC Foundry, galibi muna samar da abubuwansimintin tagullata hanyar simintin yashi kore, simintin yashi mai rufi,zuba jarikuma don manyan simintin gyare-gyaren tagulla, muna kuma ɗaukar tsarin simintin kumfa da ya ɓace. Gabaɗaya, simintin gyare-gyaren tagulla da aka samar ta hanyar simintin yashi sune babban nau'i a cikin kafuwar mu.

Gilashin jan ƙarfe tare da tutiya a matsayin babban abin haɗawa ana kiransa tagulla. Copper-zinc binary alloy ana kiransa tagulla na yau da kullun, kuma tagulla na ternary, quaternary ko Multi-element brass da aka samar ta hanyar ƙara ƙaramin adadin wasu abubuwa akan tushen ƙarfe-zinc alloy ana kiransa tagulla na musamman. Ana amfani da tagulla don samar da tagulla don yin simintin gyaran kafa. Ana amfani da simintin ƙarfe a ko'ina a cikin masana'anta, bawul da famfo, jiragen ruwa, jirgin sama, motoci, gini da sauran sassan masana'antu, suna ɗaukar wani nauyi a cikin kayan ƙarfe mara nauyi, ƙirƙirar simintin tagulla.

Idan aka kwatanta da tagulla da tagulla, ƙaƙƙarfan solubility na zinc a cikin jan karfe yana da girma sosai. A karkashin ma'aunin zafin jiki na al'ada, kusan kashi 37% na zinc za a iya narkar da su cikin tagulla, kuma kusan kashi 30% na zinc za a iya narkar da su a cikin yanayin simintin gyare-gyare, yayin da tin tagulla A cikin yanayin simintin, babban juzu'i na ingantaccen solubility na tin. a cikin jan karfe ne kawai 5% zuwa 6%. Yawan juzu'i na m solubility na aluminum tagulla a cikin jan karfe ne kawai 7% zuwa 8%. Sabili da haka, zinc yana da tasiri mai ƙarfi mai ƙarfi mai ƙarfi a cikin jan ƙarfe. A lokaci guda kuma, mafi yawan abubuwan da ke haɗawa kuma za a iya narkar da su a cikin tagulla zuwa digiri daban-daban , Ƙara inganta kayan aikin injiniya, don haka tagulla, musamman ma wasu na musamman na tagulla yana da halaye na ƙarfin ƙarfi. Farashin zinc ya yi ƙasa da na aluminum, jan ƙarfe, da tin, kuma yana da wadatar albarkatu. Adadin zinc da aka saka a cikin tagulla yana da girma sosai, don haka farashin tagulla ya yi ƙasa da tagulla na kwano da tagulla na aluminum. Brass yana da ƙaramin ƙarfi mai ƙarfi na kewayon zafin jiki, ruwa mai kyau, da narke mai dacewa.

Saboda tagulla yana da halayen da aka ambata a sama, ƙaramin farashi da kyakkyawan aikin tarkace da alumin tag na tagulla. Duk da haka, juriya na lalacewa da juriya na tagulla ba su da kyau kamar tagulla, musamman juriya da juriya na tagulla na yau da kullun. Sai kawai lokacin da aka ƙara wasu abubuwan gami don samar da tagulla na musamman daban-daban, juriyar sa da juriya ta inganta kuma an inganta su.

A matsayin yashi mai taurin kai, yashin guduro na furan da ba a gasa ba ana amfani da shi sosai don yin simintin yashin baƙin ƙarfe mai launin toka da matakan simintin ƙarfe. Za a ƙarfafa saman ƙirar yashi zuwa yanayi mai wuya bayan an ƙone rufin. Don haka, ana iya amfani da aikin simintin yashi na farin resin don samar da sassa na simintin ƙarfe masu matsakaici da manyan girma, daga dubun kilogiram zuwa ko da ton na ton. Tare da ingantacciyar ingancin ƙasa, juriyar juriya mai ƙarfi da ƙarancin lahani, ana iya amfani da matakan simintin yashi na fure don samar da hadaddun sassa na simintin.

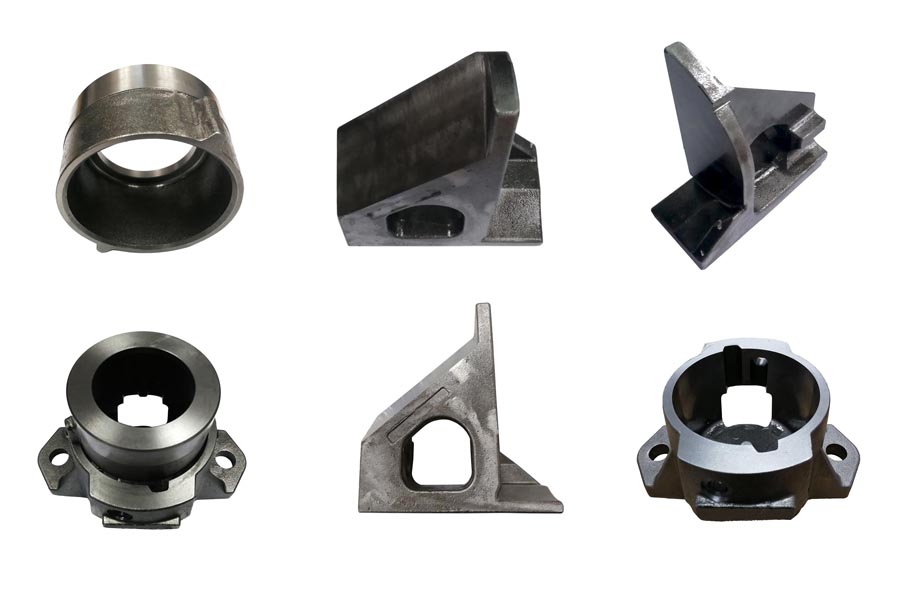

RMC yana amfani da tsarin simintin yashi na No-bake don samar da simintin ƙarfe, simintin bakin karfe, simintin ƙarfe, da simintin ƙarfe mai launin toka. A cikin tsarin No-Bake, ana yin gyare-gyaren yashi ta hanyar itace ko ƙirar ƙarfe. Yashi na hatsi mai laushi yana haɗuwa tare da mai ɗaure resin a cikin mahaɗin yashi mai sauri sannan a sauke a cikin akwati da ke dauke da samfurin. Bayan 'yan mintoci kaɗan, cakuda mai yashi ya taurare kanta kuma an cire m daga alamu. Sand Cores don ƙirƙirar tsarin ciki na simintin gyare-gyare ana yin su ta amfani da tsari iri ɗaya a lokaci guda. Bayan an haɗu da maƙalli da ƙirar waje, an rufe su kuma an shirya su don zubar da ƙarfe. Wasu abubuwa, kamar simintin ƙarfe na ductile, suna buƙatar kulawa ta musamman na ƙarfe kafin a zubo. Tsarin simintin No-Bake yana da sassauƙa sosai don yana ba da damar yin simintin ƙarfe da simintin ƙarfe don kiyaye madaidaicin haƙuri yayin da kuma yana iya ɗaukar girman sashi daga dubun gram har zuwa ton na ton.

Matakan Bake Shell Tsari:

Babu gasa tsari ne na simintin simintin gyare-gyare wanda ya haɗa da yin amfani da mahaɗar sinadarai don haɗa yashin ƙera. Ana isar da yashi zuwa tashar cike da ƙera a shirye-shiryen cika ƙura. Ana amfani da mahaɗa don haɗa yashi tare da mai ɗaure sinadarai da mai kara kuzari. Yayin da yashi ke fita daga mahaɗin, mai ɗaure ya fara tsarin sinadarai na taurin. Ana iya amfani da wannan hanya na cikawar ƙirƙira ga kowane rabi na mold (jimama da ja). Kowane gyaggyarawa rabin sai a haɗa shi don samar da mold mai ƙarfi da yawa. Sa'an nan kuma ana amfani da jujjuyawar don cire rabin ƙirjin daga cikin akwatin ƙirar. Bayan yashi ya saita, ana iya shafa wankin kyallen. Na'urori, idan an buƙata, ana saita su a cikin ja kuma an rufe juzu'i akan muryoyin don kammala ƙirar. Motoci masu sarrafa gyare-gyare da na'urori masu ɗaukar hoto suna matsar da ƙirar zuwa wuri don zubawa. Da zarar an zuba, ana barin ƙwayar ta yi sanyi kafin girgiza. Tsarin girgizawa ya haɗa da karya yashin da aka ƙera daga simintin. Daga nan za a ci gaba da yin simintin gyare-gyare zuwa wurin kammala simintin gyare-gyare don cirewa mai tashi, kammala simintin da kammalawa. Yashi da aka ƙera ana ƙara karyewa har sai an mayar da yashin zuwa girman hatsi. Yanzu ana iya dawo da yashi don sake amfani da shi a aikin simintin gyaran kafa ko cire shi don zubarwa. Gyaran zafi shine mafi inganci, cikakkiyar hanyar rashin gyaran yashin gasa.

| Kayayyakin simintin gyaran fuska na Shell Mold a Gidan Kafa na RMC | |

| Karfe & Alloys | Shahararen daraja |

| Grey Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| Ƙarfin Simintin Ruwa (Nodular). | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Karfe Karfe | C20, C25, C30, C45 |

| Alloy Karfe | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Bakin Karfe | Bakin Karfe na Ferritic, Bakin Karfe Martensitic, Bakin Karfe Austenitic, Hazo Hardening Bakin Karfe, Duplex Bakin Karfe |

| Aluminum Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Brass / Copper na tushen Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standard: ASTM, SAE, AISI, GOST, DIN, EN, ISO, da GB | |