OEM al'ada injin simintin simintin gyare-gyare na baƙin ƙarfe baƙin ƙarfe da spheroidal graphite (SG) ductile nodular simintin ƙarfe tare da magani mai zafi, jiyya na ƙasa da sabis na mashin ɗin CNC.

Vacuum simintin kuma ana kiransa simintin simintin gyare-gyare mara kyau, Rage simintin simintin gyare-gyare ko V. Yin simintin matsi yana buƙatar amfani da kayan aikin haƙon iska don fitar da iskar da ke cikin simintin simintin, sannan a yi amfani da bambancin matsa lamba tsakanin ciki da wajen ƙirar don rufe fim ɗin filastik mai zafi akan tsari da samfuri. Samfurin simintin gyare-gyaren zai zama mai ƙarfi da zai iya jure narkakken ƙarfe yayin yin simintin. Bayan samun injin injin, cika akwatin yashi da busasshiyar yashi ba tare da ɗaure ba, sannan a rufe saman saman yashi da fim ɗin robobi, sannan a saka vacuum don sanya yashin ya tsaya tsayin daka. Bayan haka, cire mold, sanya ginshiƙan yashi, rufe ƙirar don yin komai a shirye don zubawa. A ƙarshe, ana samun simintin gyare-gyaren bayan an sanyaya narkakken ƙarfe da ƙarfafa.

| Bataccen Simintin Kumfa vs Vacuum Casting | ||

| Abu | Batar da Kumfa | Vacuum Casting |

| Dace da Castings | Simintin gyare-gyare kanana da matsakaita tare da hadaddun cavities, kamar toshe injin, murfin injin | Matsakaici da manyan simintin gyare-gyare tare da ƴan ko babu kogo, kamar simintin ƙarfe na ƙarfe, gidaje na axle na simintin ƙarfe |

| Samfura da Faranti | Hanyoyin kumfa da aka yi ta hanyar gyare-gyare | Samfura tare da akwatin tsotsa |

| Akwatin Sand | Shaye-shaye na kasa ko biyar | Shaye-shaye na bangarori hudu ko tare da bututun shaye-shaye |

| Fim ɗin Fim | An rufe murfin saman da fina-finai na filastik | Dukkan bangarorin biyu na rabi na akwatin yashi an rufe su da fina-finai na filastik |

| Kayan shafawa | Fenti na tushen ruwa tare da rufi mai kauri | Fenti na tushen barasa tare da murfin bakin ciki |

| Yashi Molding | Yashi mai bushewa | Yashi bushe mai kyau |

| Gyaran Jijjiga | 3D Jijjiga | Vibration na tsaye ko a tsaye |

| Zubawa | Zuba Mara Kyau | Zuba Mara Kyau |

| Tsarin Yashi | Rage matsa lamba mara kyau, juya akwatin don sauke yashi, sannan a sake amfani da yashi | Sauke matsa lamba mara kyau, sannan busassun yashi ya faɗi cikin allon, kuma ana sake yin amfani da yashi |

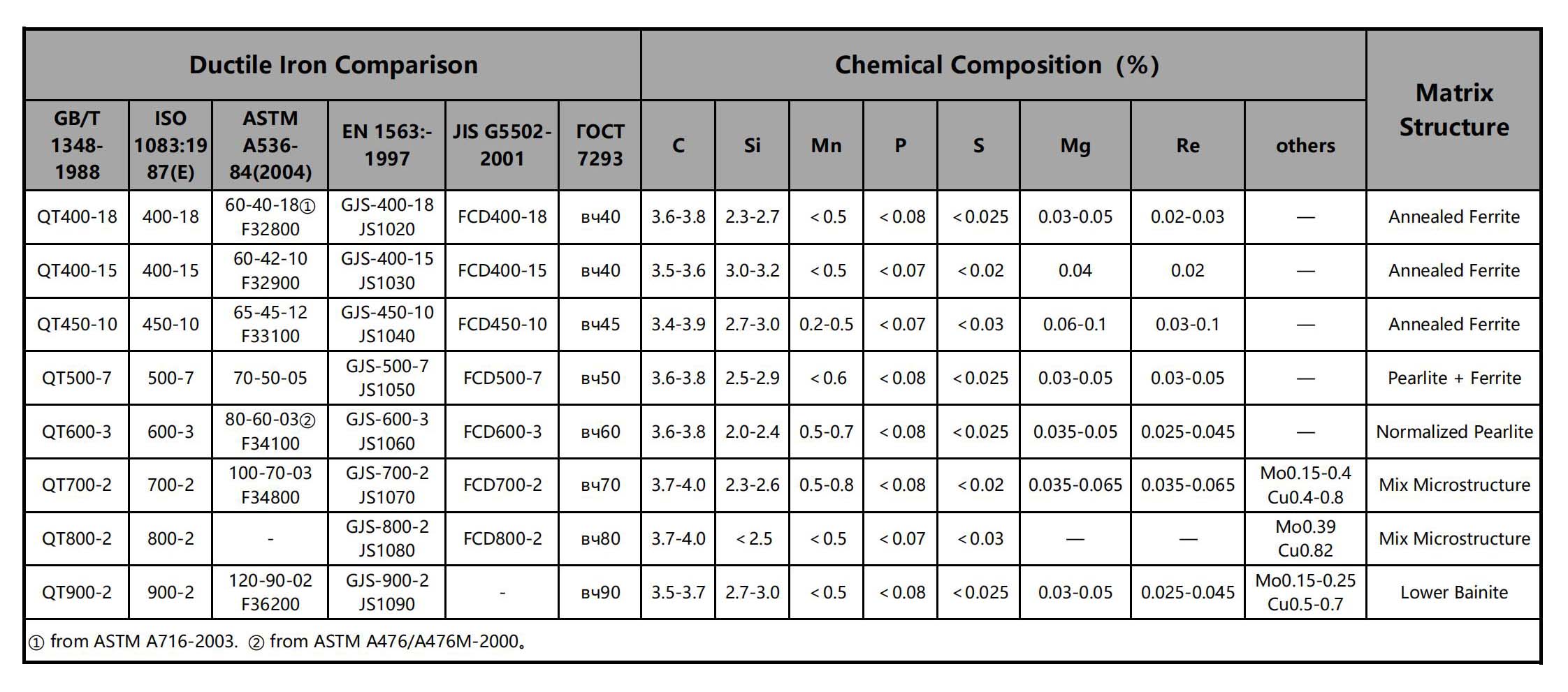

Iron simintin gyare-gyare, wanda kuma ake kira nodular cast iron, spheroidal graphite cast iron ko kawai SG iron a takaice, yana wakiltar rukunin simintin ƙarfe. Nodular simintin ƙarfe yana samun graphite nodular ta hanyar spheroidization da inoculation magani, wanda yadda ya kamata inganta inji Properties na simintin ƙarfe, musamman roba da taurin, don samun mafi girma ƙarfi fiye da carbon karfe.

Simintin gyare-gyaren ƙarfe yana da mafi kyawun aikin ɗaukar girgiza fiye da carbon karfe, yayin da simintin ƙarfe na carbon yana da mafi kyawun walƙiya. Kuma zuwa wani matsayi, ductile iorn simintin gyare-gyare na iya samun wasu wasan kwaikwayon na juriya da lalacewa da tsatsa. Don haka ana iya amfani da simintin ƙarfe don wasu gidajen famfo ko tsarin samar da ruwa. Koyaya, har yanzu muna buƙatar yin taka tsantsan don kare su daga sawa da tsatsa.

Ƙarfin ƙarfe ba abu ɗaya ba ne amma yana cikin rukuni na kayan da za a iya samar da su don samun nau'o'in kaddarorin ta hanyar sarrafa microstructure. Halayen ma'anar gama gari na wannan rukuni na kayan shine siffar graphite. A cikin baƙin ƙarfe ductile, graphite yana cikin nau'i na nodules maimakon flakes kamar yadda yake a cikin baƙin ƙarfe. Siffa mai kaifi na flakes na graphite yana haifar da maƙasudin maida hankali a cikin matrix na ƙarfe da siffar zagaye na nodules ƙasa da haka, don haka hana ƙirƙirar fashe da samar da ingantaccen ductility wanda ke ba da gami da sunansa. Don haka gabaɗaya magana, idan baƙin ƙarfe na ductile zai iya biyan buƙatun ku, baƙin ƙarfe na ductile zai iya zama zaɓinku na farko, maimakon ƙarfe na carbon don simintin ku.