Cobalt tushen gami zuba jari simintin kayayyakin daga kasar Sin asali kafuwar tare da zafi magani da CNC machining sabis

| Karfe donTsarin Zuba Jariku RMC | |||

| Kashi | Babban darajar China | darajar Amurka | Jamus Grade |

| Karfe Karfe | ZG15, ZG20, ZG25, ZG35, ZG45, ZG55, Q235, Q345, Q420 | 1008, 1015, 1018, 1020, 1025, 1030, 1035, 1040, 1045, 1050, 1060, 1070, WC6, WCC, WCB, WCA, LCB | 1.0570, 1.0558, 1.1191, 1.0619, 1.0446, GS38, GS45, GS52, GS60, 1.0601, C20, C25, C30, C45 |

| Ƙananan Ƙarfe Karfe | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V | 1117, 4130, 4140, 4340, 6150, 5140, WC6, LCB, Gr.13Q, 8620, 8625, 8630, 8640, H13 | GS20Mn5, GS15CrNi6, GS16MnCr5, GS25CrMo4V, GS42CrMo4, S50CrV4, 34CrNiMo6, 50CrMo4, G-X35CrMo17, 1.1131, 1.0037, 1.0122, 1.2162, 1.2542, 1.6511, 1.6523, 1.6580, 1, 1,713. 1.7225, 1.7227, 1.7228, 1.7231, 1.7321, 1.8519, ST37, ST52 |

| Babban Mn Karfe | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Kayan aiki Karfe | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Karfe Resistant Heat | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Alloy-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, Farashin 625 | 2.4815, 2.4879, 2.4680 | |

| Cobalt-base Alloy | UMC50, 670, Darasi na 31 | 2.4778 | |

Cobalt tushen gami ne mai wuya gami da zai iya jure iri daban-daban na lalacewa, lalata da kuma high zafin jiki hadawan abu da iskar shaka. Abubuwan da aka yi amfani da su na Cobalt sun dogara ne akan cobalt a matsayin babban sashi, yana dauke da adadi mai yawa na nickel, daɗaɗɗen sinadarai irin su chromium, tungsten da ƙananan adadin abubuwan da aka haɗa da su kamar molybdenum, niobium, tantalum, titanium, lanthanum, da baƙin ƙarfe lokaci-lokaci. . Dangane da nau'in abun da ke cikin gawa, ana iya yin gawa ta cobalt ta zama waya ta walda, kuma ana iya amfani da foda don waldawa mai ƙarfi, feshin zafi, waldawar feshi da sauran matakai, kuma ana iya yin ta ta zama simintin gyare-gyare. , Forgings da foda karfe sassa. Ƙarshen amfani da ƙarshen, ana iya raba abubuwan tushen cobalt zuwa galoli masu jurewa na cobalt, galoli masu zafi na tushen cobalt da tushen cobalt na tushen maganin lalata. A cikin yanayin aiki gabaɗaya, duka biyun suna da juriya da juriya da zafi mai ƙarfi ko juriya da lalacewa. Wasu yanayin aiki na iya buƙatar babban zafin jiki, juriya da lalata a lokaci guda. Mafi hadaddun yanayin aiki, mafi kyawun fa'idodin abubuwan haɗin gwiwar cobalt.

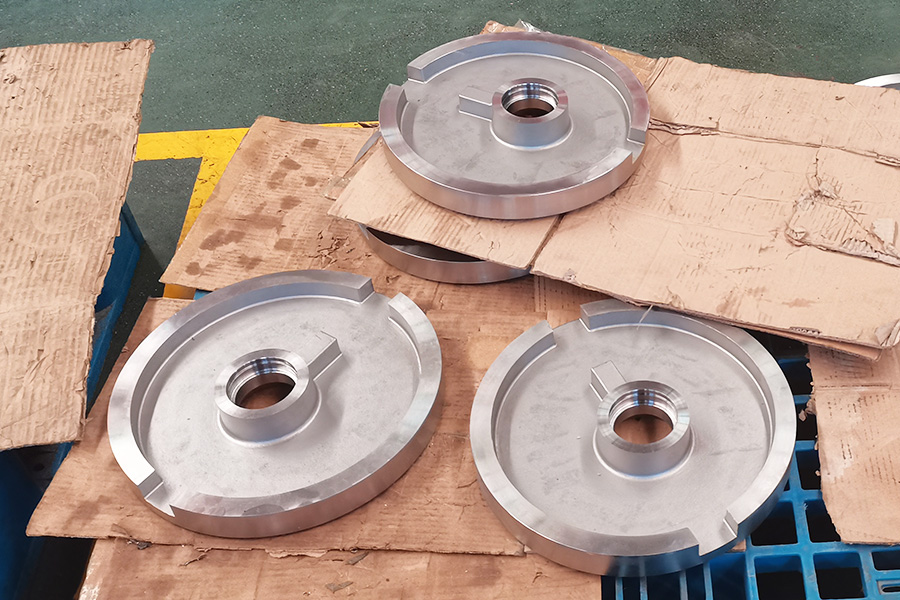

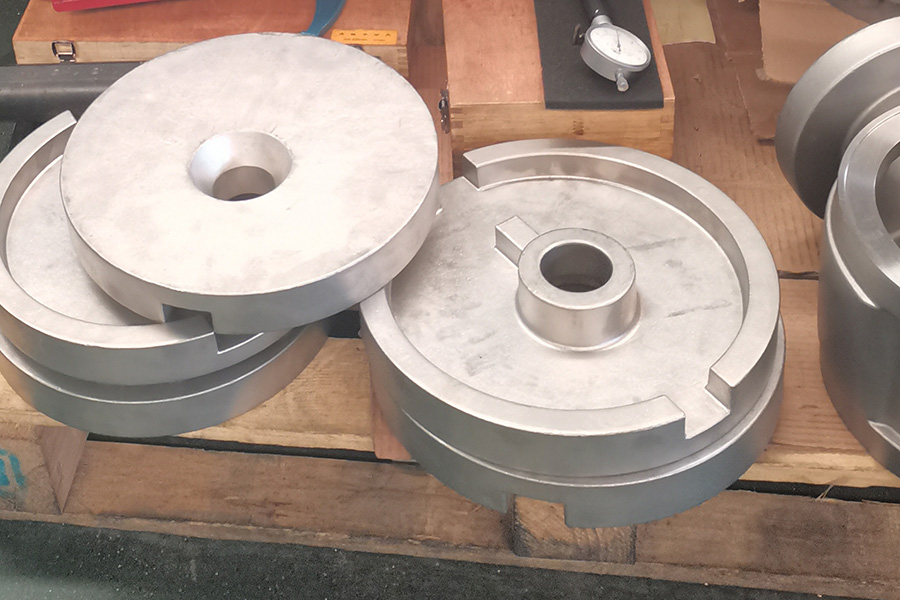

Kayayyakin Kayan Gishiri na Cobalt

Babban carbides a cikin superalloys na tushen cobalt sune MC, M23C6 da M6C. A cikin simintin gyare-gyare na tushen cobalt, M23C6 yana haɗe tsakanin iyakokin hatsi da dendrites yayin jinkirin sanyaya. A cikin wasu gami, M23C6 mai kyau na iya ƙirƙirar eutectic tare da matrix γ. MC carbide barbashi suna da girma da yawa kai tsaye suna da tasiri mai mahimmanci akan rarrabuwa, don haka tasirin ƙarfafawa akan gami ba a bayyane yake ba, yayin da tarwatsawar carbides suna da tasirin ƙarfafawa mai kyau. Carbides da ke kan iyakar hatsi (yafi M23C6) na iya hana shingen iyakar hatsi, don haka inganta ƙarfin juriya. Microstructure na cobalt-tushen superalloy HA-31 (X-40) wani tarwatsa ƙarfafa lokaci ne (CoCrW) 6 C-type carbide. Fuskokin da ke kusa da abubuwan da ke bayyana a cikin wasu abubuwan haɗin gwiwa na tushen cobalt, irin su sigma lokaci yana da illa kuma yana sa gami da tsinke.

Ƙarfafawar thermal na carbides a cikin kayan haɗin gwiwar cobalt yana da kyau. Lokacin da zafin jiki ya tashi, haɓakar haɓakar tarin carbide yana da hankali fiye da ƙimar girma na lokaci na γ a cikin gami da tushen nickel, kuma zazzabi na sake narkewa cikin matrix shima yana da girma (har zuwa 1100 ° C). . Sabili da haka, lokacin da zafin jiki ya tashi, haɗin tushen cobalt Ƙarfin gami gabaɗaya yana raguwa sannu a hankali. Alloys na tushen Cobalt suna da kyakkyawan juriyar lalatawar thermal. Dalilin da ya sa abubuwan da ake amfani da su na cobalt sun fi nickel na tushen nickel a wannan girmamawa shi ne cewa wurin narkewa na cobalt sulfide (irin su Co-Co4S3 eutectic, 877 ℃) ya fi na nickel (Misali, Ni-Ni3S2 eutectic). (645°C) yana da girma, kuma adadin sulfur a cikin cobalt ya yi ƙasa da na nickel kuma saboda yawancin Cobalt-tushen gami da mafi girma chromium abun ciki fiye da nickel tushen gami, za su iya samar da wani m Layer na alkali karfe sulfate (kamar Cr2O3 m Layer wanda aka lalatar da Na2SO4) a kan surface na gami Duk da haka, da hadawan abu da iskar shaka juriya na Alloys na tushen cobalt gabaɗaya sun fi na tushen nickel ƙasa sosai.

Daban-daban da sauran superalloys, superalloys na tushen cobalt ba a ƙarfafa su ta hanyar yanayin hazo da aka ba da oda da ke da alaƙa da matrix, amma sun ƙunshi matrix fcc austenite wanda aka ƙarfafa ingantaccen bayani da ƙaramin adadin carbides da aka rarraba a cikin matrix. Simintin gyare-gyare na tushen cobalt superalloys ya dogara kacokan akan ƙarfafa carbide. Tsaftataccen lu'ulu'u na cobalt suna da tsarin lu'ulu'u na kusa da hexagonal (hcp) da ke ƙasa da 417°C, wanda ke canzawa zuwa fcc a yanayin zafi mafi girma. Don guje wa wannan sauyi yayin amfani da superalloys na tushen cobalt, kusan dukkanin abubuwan haɗin gwiwa na tushen cobalt ana haɗa su da nickel don daidaita tsarin daga zafin ɗaki zuwa yanayin narkewa. Alloys na tushen Cobalt suna da alaƙar daɗaɗɗen karyewar damuwa-zazzabi, amma suna nuna juriya na lalata yanayin zafi a yanayin zafi sama da 1000°C fiye da sauran yanayin zafi.

Haɓakar Zafi na Alloys na tushen Cobalt

Girma da rarraba barbashi na carbide da girman hatsi a cikin kayan haɗin gwiwar cobalt suna da matukar damuwa ga tsarin simintin. Domin samun ƙarfin jimiri da ake buƙata da kaddarorin gajiyar zafin jiki na sassan simintin simintin simintin gyare-gyare na tushen cobalt, dole ne a sarrafa sigogin tsarin simintin. Alloys na tushen Cobalt suna buƙatar maganin zafi, galibi don sarrafa hazo na carbide. Domin simintin gyare-gyare na tushen cobalt, da farko aiwatar da babban zafin jiki m maganin maganin, yawanci a zafin jiki na kusan 1150 ° C, ta yadda duk manyan carbides, ciki har da wasu nau'in carbides na MC, suna narkar da su cikin ingantaccen bayani; to, ana gudanar da maganin tsufa a 870-980 ° C. Sa carbide ya sake yin hazo.

Maki na gama gari na Kayayyakin tushen Cobalt

Matsakaicin nau'ikan nau'ikan nau'ikan zafin jiki na cobalt na yau da kullun sune: 2.4778 (bisa ga DIN EN 10295) Hayness 188, Haynes 25 (L-605), Alloy S-816, UMCo-50, MP-159, FSX-414, X -40, Stellite 6B, Grade 31, da dai sauransu, Alamomin kasar Sin sune: GH5188 (GH188), GH159, GH605, K640, DZ40M da sauransu.

Aikace-aikace na tushen Cobalt Alloy Castings

Gabaɗaya, superalloys na tushen cobalt ba su da madaidaitan matakan ƙarfafawa. Kodayake ƙarfin a matsakaicin zafin jiki yana da ƙasa (kawai 50-75% na abubuwan haɗin nickel), suna da ƙarfi mafi girma, juriya mai ƙarfi na thermal, juriya abrasion, mafi kyawun weldability da juriya na thermal juriya sama da zafin jiki na 980 ° C. Don haka, simintin gyare-gyare na tushen cobalt sun fi dacewa don yin vanes na jagora da bututun bututun jagora don injunan jet na jirgin sama, injin injin masana'antu, injin injin ruwa, da injin dizal, da sauransu.