Simintin simintin gyare-gyare, wanda kuma ake kira simintin bakin karfe, yana nufin simintin simintin gyare-gyare, wanda ke nuna ƙarfin juriya ga lalatawa a cikin nau'ikan ƙayyadaddun ƙayyadaddun kafofin watsa labaru na musamman ko yanayin da lalata da abubuwan inji ke zama tare.

| Ra'ayoyi masu sauri don Austenitic Bakin Karfe | |

| Babban Haɗin Sinadari | Cr, Ni, C, Mo, Ku, Si, Nb, Ti |

| Ayyuka | Ba Magnetic ba, babban tauri, babban filastik, ƙarancin ƙarfi |

| Ma'anarsa | Bakin karfe tare da tsarin austenitic a dakin da zafin jiki |

| Makin Wakili | 304, 316, 1.4310, 1.4301, 1.4408 |

| Injin iya aiki | Gaskiya |

| Weldability | Gabaɗaya mai kyau sosai |

| Yawan Amfani | Injin abinci, Hardware, Sarrafa sinadarai...da sauransu |

Bakin karfe yana da ƙaramin abun ciki na chromium na 10.5%, yana mai da shi mafi juriya ga gurbataccen muhallin ruwa da iskar oxygen. Yana da juriya sosai kuma yana jure lalacewa, yana ba da ingantacciyar injin aiki, kuma sananne ne don kyawun kyawun sa. Simintin saka hannun jari na bakin karfe yana da "lalata" lokacin da aka yi amfani da shi a cikin mahalli na ruwa da tururi da ke ƙasa da 1200°F (650°C) da kuma "mai jure zafi" lokacin amfani da sama da wannan zafin jiki.

Austenitic bakin karfeyana nufin bakin karfe tare da tsarin austenitic a zafin jiki. Austenitic bakin karfe yana daya daga cikin nau'o'i biyar na bakin karfe ta tsarin crystalline (tare da ferritic, martensitic, duplex da hazo mai taurare). A wasu yankuna, bakin karfe na austenite kuma ana kiransa jerin bakin karfe 300. Lokacin da karfe ya ƙunshi kusan 18% Cr, 8% -25% Ni, da kusan 0.1% C, yana da tsayayyen tsarin austenite. Bakin karfe na Austenitic chromium-nickel ya hada da sanannen karfen 18Cr-8Ni da babban silsilar karfen Cr-Ni da aka kirkira ta hanyar kara abun ciki na Cr da Ni tare da kara Mo, Cu, Si, Nb, Ti da sauran abubuwa akan wannan. Austenitic bakin karfe ba Magnetic ba ne kuma yana da babban tauri da filastik, amma ƙarfinsa kaɗan ne, kuma ba shi yiwuwa a ƙarfafa shi ta hanyar canjin lokaci. Ana iya ƙarfafa shi kawai ta hanyar aikin sanyi. Idan an ƙara abubuwa kamar S, Ca, Se, Te, yana da kyawawan kaddarorin injina.

Austenitic bakin karfe kuma na iya samar da simintin gyare-gyare. Domin inganta ruwan narkakkar karfe da inganta aikin simintin gyare-gyare, ya kamata a daidaita abun da ke ciki na simintin ƙarfe ta hanyar ƙara abun ciki na siliki, faɗaɗa kewayon chromium da nickel abun ciki, da ƙara iyakar ƙazanta na sulfur na ƙazanta.

Austenitic bakin karfe ya zama m-maganin bi da kafin amfani, don haka kamar yadda ya kara da m bayani na daban-daban precipitates kamar carbides a cikin karfe a cikin austenite matrix, yayin da kuma homogenizing da tsarin da kuma kawar da danniya, don haka kamar yadda don tabbatar da kyau kwarai Lala juriya da kuma inji Properties. Madaidaicin tsarin maganin maganin shine sanyaya ruwa bayan dumama a 1050~1150 ℃ ( sassan bakin ciki kuma ana iya sanyaya iska). Maganin zafin jiki na maganin ya dogara da digiri na alloying na karfe: Molybdenum-free ko low-molybdenum karfe maki ya zama ƙasa (≤1100 ℃), kuma mafi girma alloyed maki kamar 00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, da dai sauransu ya zama mafi girma ( 1080 ~ 1150) ℃).

Austenitic 304 bakin karfe farantin karfe, wanda aka ce yana kawo tsatsa mai ƙarfi da juriya na lalata, kuma yana da kyakkyawan filastik da tauri, wanda ya dace da tambari da ƙira. Tare da nauyin 7.93 g / cm3, 304 bakin karfe shine bakin karfe na kowa, wanda kuma aka sani da 18/8 bakin karfe a cikin masana'antu. Kayan sa na karfe suna da juriya ga yanayin zafi kuma suna da kyawawan kaddarorin sarrafawa, don haka ana amfani da su sosai a masana'antu da masana'antar kayan ado da masana'antar abinci da magunguna.

Daidai Matsayin Bakin Karfe | |||||||

| Categories | AISI | W-tafi | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic da Ferritic Bakin Karfe | 420 C | 1.4034 | X43Cr16 | ||||

| 440 B/1 | 1.4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7Cr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | Saukewa: X12CRS13 | 416 S21 | 2380 | F.3411 | Saukewa: X12CrS13 | |

| 410 | 1.4006 | X 10 Cr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6Cr 17 | 430 S17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | Saukewa: X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S17 | 2325 | - | Saukewa: X8CrMo17 | |

| 430 Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S17 | - | - | X6CrTi12 | |

| Austenitic Bakin Karfe | 304 | 1.4301 | X5 CrNi 18 9 | 304 S15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304l | 1.4306 | X2 CrNiS 18 9 | 304 S12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316l | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316l | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S33 | 2343 | - | X8CrNiMo 17 13 | |

| 317l | 1.4438 | X2 CrNiMo 18 16 | 317 S12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316 Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Bakin Karfe | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | Saukewa: X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Kayayyakin ƙarfe da ba na ƙarfe ba don Zuba Jari, Tsarin Simintin Kakin Kakin da Ya ɓace:

- • Iron Grey: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10~GG40.

- • Iron Ductile ko Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- • Karfe Karfe: AISI 1020 - AISI 1060, C30, C40, C45.

- • Karfe Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo ... da dai sauransu a kan bukatar.

- • Bakin Karfe: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 da sauran bakin karfe.

- • Brass, Red Copper, Bronze ko wasu ƙarfe na ƙarfe na tushen Copper: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

- • Sauran Kayayyaki gwargwadon buƙatunku na musamman ko bisa ga ASTM, SAE, AISI, ACI, DIN, EN, ISO, da ma'aunin GB

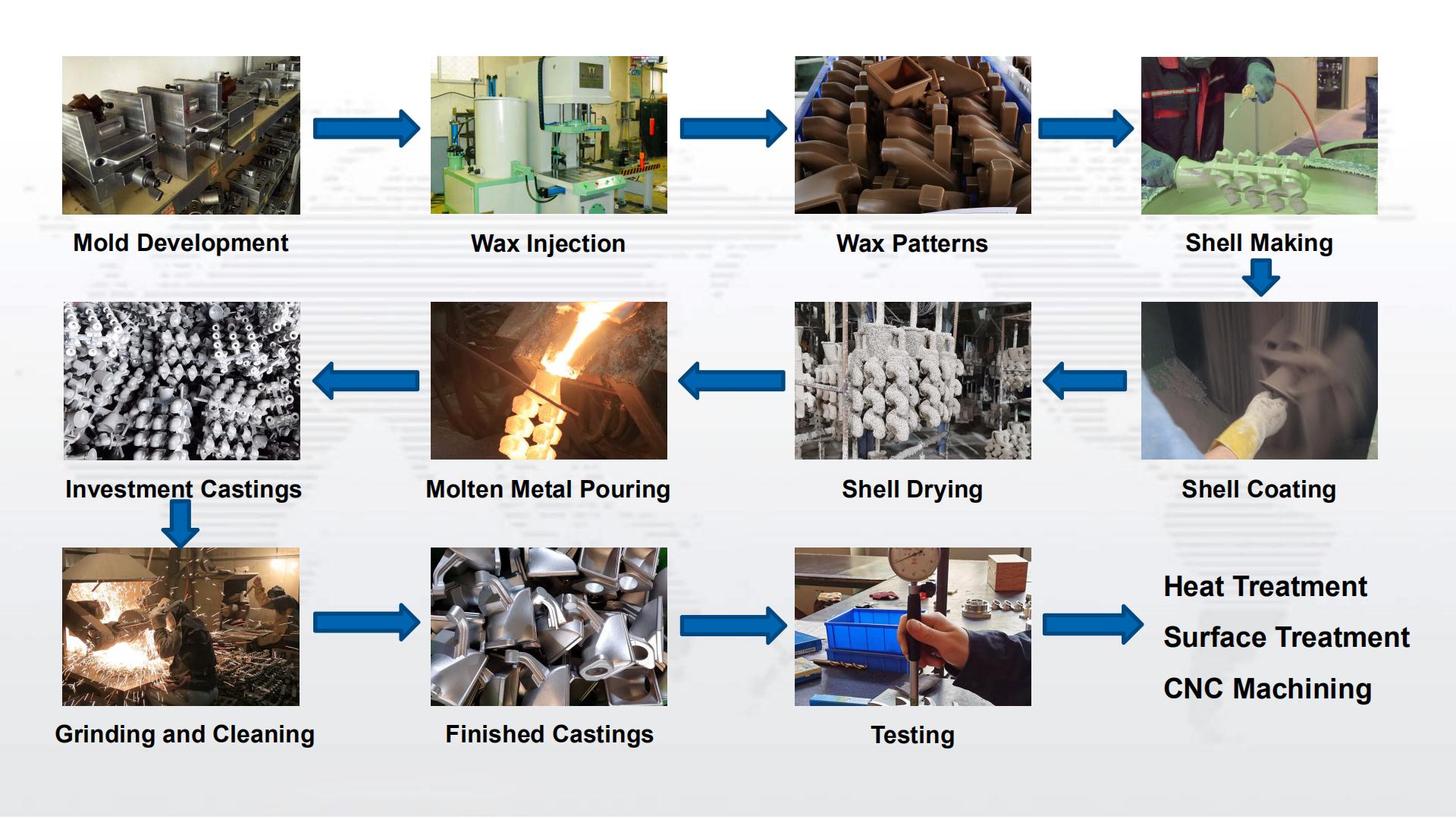

Matakan da ke cikin tsarin ko simintin kakin zuma da aka rasa sune:

- • Ƙirƙirar ƙirar kakin zuma ko kwafi

- • Sanya ƙirar kakin zuma

- • Saka hannun jari na kakin zuma

- • Cire samfurin kakin zuma ta hanyar kona shi (cikin tanderun ko a cikin ruwan zafi) don ƙirƙirar mold.

- • Ƙaddamar da narkakkar ƙarfe a zuba a cikin ƙura

- • sanyaya da ƙarfi

- • Cire sprue daga simintin gyaran kafa

- • Kammala da goge ƙãre simintin saka hannun jari

Maganin zafi na AISI 316 Bakin Karfe:

Yi zafi zuwa 1900°F (1040°C) ƙaramar, riƙe don isashen lokaci, kashewa cikin ruwa ko saurin sanyi ta wasu hanyoyi. AISI 316 daidai yake da CF8M/F316 da ma'aunin Sinanci 0Cr17Ni12Mo2. AISI 314 molybdenum ne mai gyaggyarawa na AISI 304 gami da simintin gyare-gyaren da aka yi na CF8M Bakin Karfe. Kasancewar molybdenum yana ƙara juriyar lalata gabaɗaya da juriya ga rami ta chlorides. Ana amfani da alluran a cikin yanayi mai sauƙi na acidic da alkaline kuma don sarrafa citric, oxalic da phosphoric acid.