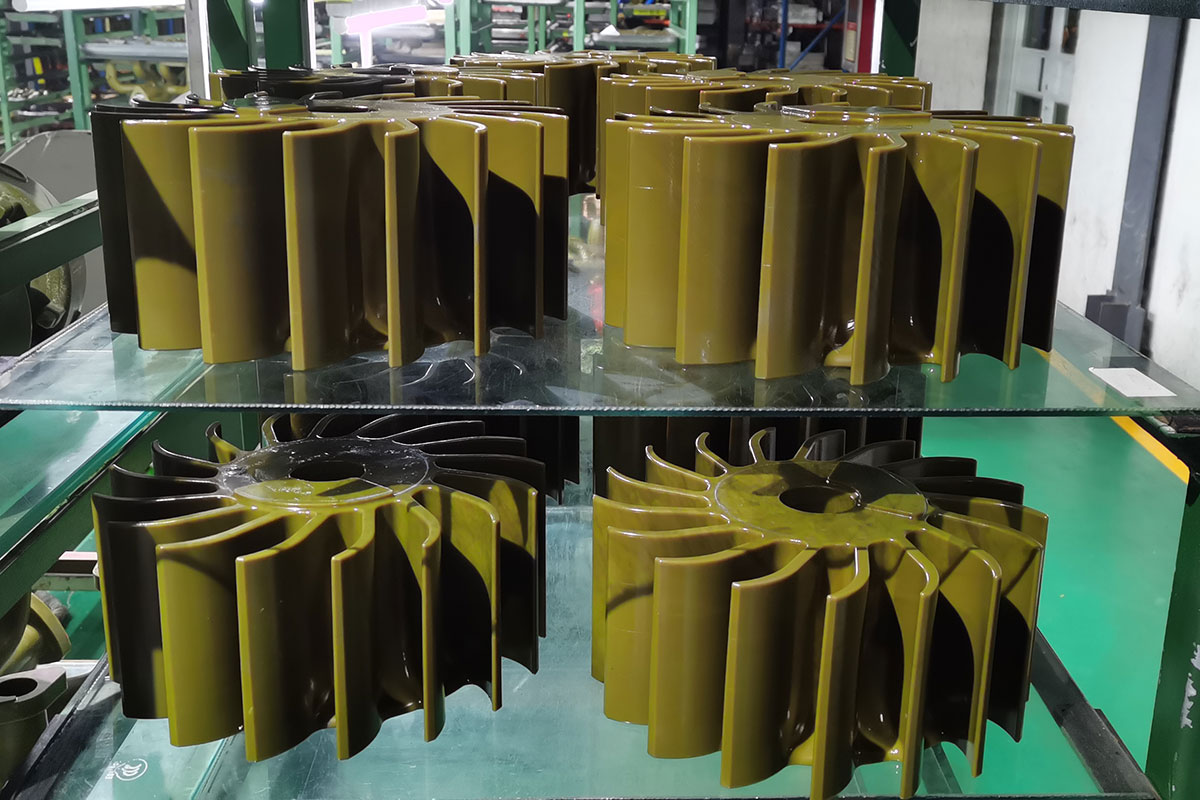

China OEM al'ada bakin karfe impeller taasarar kakin zuma tsarin simintin gyaran kafa.

Abubuwan abubuwan haɗin gwal na kowane nickel-base ko bakin karfe zuba jari sune chromium, nickel, da molybdenum (ko "moly"). Wadannan sassa uku za su tantance tsarin hatsin simintin da kaddarorin injina kuma za su zama kayan aiki wajen iyawar simintin yaƙar zafi, lalacewa, da lalata.

Bakin karfe yana da ƙaramin abun ciki na chromium na 10.5%, yana mai da shi mafi juriya ga gurbataccen muhallin ruwa da iskar oxygen. Duk da haka, wannan ba cikakke ba ne. Bakin karfe zuba jarisimintin gyare-gyaren "lalata" ne idan aka yi amfani da su a wuraren ruwa da tururi da ke ƙasa da 1200°F (650°C) da kuma "mai jure zafi" lokacin amfani da sama da wannan zafin jiki.

Amfanin Abubuwan Zuba Jari:

- Madalla da m surface gama

- Haƙurin juzu'i masu ƙarfi.

- Siffa masu rikitarwa da rikitarwa tare da sassauƙar ƙira

- Ƙarfin jefa bangon bakin ciki don haka ɓangaren simintin gyare-gyare mai sauƙi

- Zaɓin zaɓi na ƙarfe na simintin ƙarfe da gami (na ƙarfe da mara ƙarfe)

- Ba a buƙatar daftarin aiki a cikin ƙirar ƙira.

- Rage buƙatar injiniyoyi na biyu.

- Low kayan sharar gida.

| Kayayyakin donZuba JariTsari aRMC Foundry | |||

| Kashi | Babban darajar China | darajar Amurka | Jamus Grade |

| Bakin Karfe na Ferritic | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Bakin Karfe | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic bakin karfe | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404, 80. 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Hazo Hardening Bakin Karfe | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Bakin Karfe | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| Babban Mn Karfe | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Kayan aiki Karfe | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Karfe Resistant Heat | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Alloy-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, INCOLOY600, Farashin 625 | 2.4815, 2.4879, 2.4680 | |

| Aluminum Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Alloy na Copper | H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Darasi na 31 | 2.4778 | |

| HAKURI JIN JINI | |||

| Inci | Millimeters | ||

| Girma | Hakuri | Girma | Hakuri |

| Har zuwa 0,500 | ±.004" | Har zuwa 12.0 | ± 0.10mm |

| 0.500 zuwa 1.000" | ±.006" | 12.0 zuwa 25.0 | ± 0.15mm |

| 1.000 zuwa 1.500" | ±.008" | 25.0 zuwa 37.0 | ± 0.20mm |

| 1.500 zuwa 2.000" | ±.010" | 37.0 zuwa 50.0 | ± 0.25mm |

| 2.000 zuwa 2.500" | ±.012" | 50.0 zuwa 62.0 | ± 0.30mm |

| 2.500 zuwa 3.500" | ±.014" | 62.0 zuwa 87.0 | ± 0.35mm |

| 3.500 zuwa 5.000" | ±.017" | 87.0 zuwa 125.0 | ± 0.40mm |

| 5.000 zuwa 7.500" | ±.020" | 125.0 zuwa 190.0 | ± 0.50mm |

| 7.500 zuwa 10,000" | ±.022" | 190.0 zuwa 250.0 | ± 0.57mm |

| 10.000 zuwa 12.500" | ±.025" | 250.0 zuwa 312.0 | ± 0.60mm |

| 12.500 zuwa 15.000 | ±.028" | 312.0 zuwa 375.0 | ± 0.70mm |