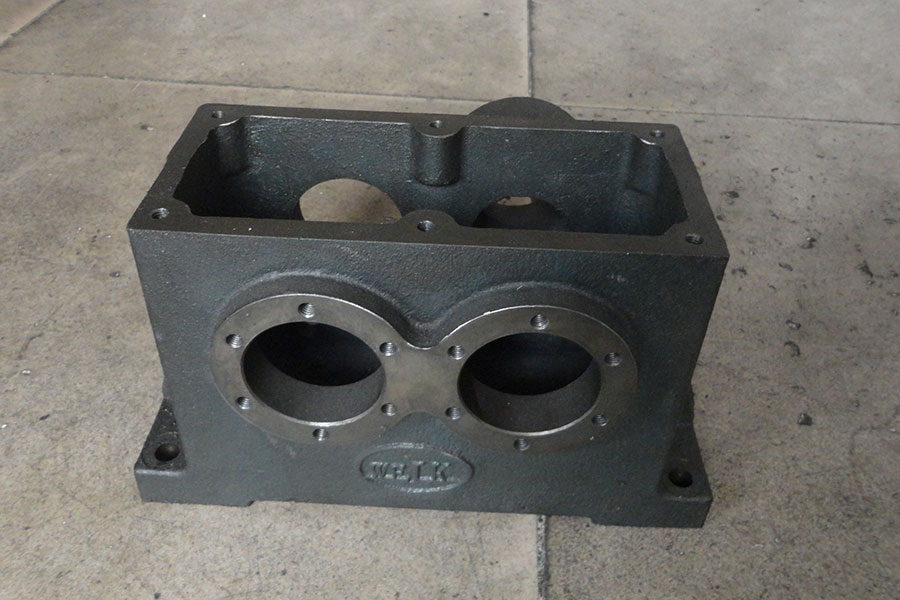

Grey simintin ƙarfe kayayyakin tayashi mold tsarida CNC machining.

An sanya wa baƙin ƙarfe launin toka suna bayan launin toka na karyewar da ya yi. Ana amfani da baƙin ƙarfe mai launin toka don gidaje inda taurin ɓangaren ke da mahimmanci fiye da ƙarfin ƙarfinsa, kamar tubalan ingin konewa na ciki, gidajen famfo, jikin bawul, akwatunan lantarki, ma'aunin nauyi da simintin ado. Babban ƙarfin wutar lantarki na simintin ƙarfe mai launin toka da ƙayyadaddun ƙarfin kai galibi ana amfani da su don yin girkin ƙarfe na simintin ƙarfe da rotors na diski.

Halin sinadari na yau da kullun don samun ƙananan ƙirar hoto shine 2.5 zuwa 4.0% carbon da 1 zuwa 3% silicon ta nauyi. Graphite na iya ɗaukar kashi 6 zuwa 10% na ƙarar baƙin ƙarfe. Silicon yana da mahimmanci don yin baƙin ƙarfe mai launin toka sabanin farin ƙarfe na simintin ƙarfe, saboda silicon wani abu ne mai daidaita graphite a cikin simintin ƙarfe, wanda ke nufin yana taimakawa gami samar da graphite maimakon ƙarfe carbides; a 3% silicon kusan babu carbon da aka gudanar a cikin sinadaran hade da baƙin ƙarfe.

Zane-zanen yana ɗaukar siffar flake mai girma uku. A cikin ma'auni biyu, kamar yadda fuskar da aka goge za ta bayyana a ƙarƙashin na'ura mai ma'ana, flakes na graphite suna bayyana a matsayin layi mai kyau. Tukwici na flakes suna aiki azaman darasi na farko; saboda haka, yana da karye. Kasancewar flakes na graphite yana sa Iron ɗin Grey cikin sauƙin aiki yayin da suke saurin fashewa cikin sauƙi a fadin faifan graphite. Iron baƙin ƙarfe shima yana da kyakkyawan ƙarfin damping don haka galibi ana amfani dashi azaman tushe don hawa kayan aikin injin.

Grey Cast Iron Mechanical Properties | |||||||

| Abu bisa ga DIN EN 1561 | Auna | Naúrar | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Ƙarfin Ƙarfin Ƙarfi | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Ƙarfin Haɓaka | Rp0,1 | MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Ƙarfin Ƙarfi | A | % | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 |

| Ƙarfin Ƙarfi | Ƙaddamarwa dB | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0.1% Ƙarfin Ƙarfi | ku 0,1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Ƙarfin Flexural | Ƙaddamarwa bB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Danniya mai ƙarfi | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Modules na elasticity | E | GPA | 78-103 | shafi na 88-113 | 103-118 | 108-137 | shafi na 123-143 |

| Lambar guba | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Brinell taurin | HB | 160-190 | 180-220 | 190-230 | 200-240 | 210-250 | |

| Halittu | Ƙaddamarwa bW | MPa | 70 | 90 | 120 | 140 | 145 |

| Tashin hankali da canjin matsa lamba | Ƙaddamar da W | MPa | 40 | 50 | 60 | 75 | 85 |

| Ƙarfin Ƙarfi | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Yawan yawa | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

Yin simintin yashi yana amfani da koren yashi (yashi mai laushi) ko busasshiyar yashi don samar da tsarin gyare-gyare. Koren simintin gyare-gyaren yashi shine tsarin simintin gyare-gyaren da aka yi amfani da shi a tarihi. Lokacin yin gyare-gyaren, ya kamata a samar da tsarin da aka yi da itace ko karfe don samar da rami mara kyau. Karfe da aka narkar da shi sai a zuba a cikin rami don samar da simintin gyare-gyare bayan sanyaya da ƙarfafawa. Yashi simintin gyare-gyare ba shi da tsada fiye da sauran hanyoyin yin simintin gyare-gyare duka don haɓaka ƙirar ƙira da ɓangaren simintin ɓangarorin. Yin simintin yashi, ko da yaushe yana nufin simintin yashi koren (idan babu bayanin musamman). Koyaya, a zamanin yau, sauran hanyoyin yin simintin suma suna amfani da yashi don yin ƙirar. Suna da nasu sunayen, kamarharsashi mold simintin gyaran kafa, farin guduro mai rufi yashi simintin gyaran kafa (babu irin gasa),rasa kumfada vacuum simintin.

Ƙarfin Simintin Yashi a RMC Foundry | ||

| Bayani | Molding ta Manual | Yin gyare-gyare ta Injin atomatik |

| Matsakaicin girman Castings | 1,500 mm × 1000 mm × 500 mm | 1,000 mm × 800 mm × 500 mm |

| Rage Nauyin Simintin Ɗaukaka | 0.5 kg - 1,000 kg | 0.5 kg - 500 kg |

| Ƙarfin shekara | 5,000 ton - 6,000 ton | 8,000 ton - 10,000 ton |

| Yin Haƙuri | Akan Buƙatu ko Ƙa'ida (ISO8062-2013 ko GB/T 6414-1999) | |

| Kayan gyare-gyare | Yashi Green, Yashi Mai Rufe Guduro | |

| Yin Casting Metal & Alloys | Ƙarfe mai launin toka, Iron Ductile, Cast Karfe, Bakin Karfe, Al Alloys, Brass, Bronze...da sauransu. | |

Amfanin Casting Yashi:

- ✔ Ƙananan Kuɗi saboda arha da kayan ƙira da za a iya sake yin amfani da su da kayan aiki masu sauƙi.

- ✔ Faɗin nauyin naúrar daga 0.10 kg zuwa 500 kgs ko ma mafi girma.

- ✔ Daban-daban Tsarin daga nau'i mai sauƙi zuwa nau'i mai rikitarwa.

- ✔ Dace da samar da bukatun na daban-daban yawa.

Haƙuri Da Yashi Ya Samu:

Hakurin yin simintin ya kasu kashi-kashi Juyin Juriya na Casting (DCT) da Hakuri na Casting Geometric (GCT). Cibiyar mu tana son yin magana da ku idan kuna da buƙatu ta musamman akan abubuwan da ake buƙata. Anan a cikin waɗannan sune jimlar juzu'i na gabaɗaya da za mu iya kaiwa ta hanyar simintin yashi koren, simintin gyare-gyaren harsashi da simintin yashi mai gasa bake ba:

- ✔ DCT Grade ta Green Sand Casting: CTG10 ~ CTG13

- ✔ Matsayin DCT ta Shell Mold Casting ko Furan Resin Sand Casting: CTG8 ~ CTG12

- ✔ GCT Grade ta Green Sand Casting: CTG6 ~ CTG8

- ✔ GCT Grade ta Shell Mold Casting ko Furan Resin Sand Casting: CTG4 ~ CTG7

Ƙarfe & Gilashin Gishiri don Tsarukan Simintin Yashi | |

| Karfe & Alloys | Shahararen daraja |

| Grey Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| Ƙarfin Simintin Ruwa (Nodular). | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Karfe Karfe | C20, C25, C30, C45 |

| Alloy Karfe | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Bakin Karfe | Bakin Karfe na Ferritic, Bakin Karfe Martensitic, Bakin Karfe Austenitic, Hazo Hardening Bakin Karfe, Duplex Bakin Karfe |

| Aluminum Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Brass / Copper na tushen Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standard: ASTM, SAE, AISI, GOST, DIN, EN, ISO, da GB | |

-

Grey Cast Iron Sand Samfur

-

Grey Cast Iron Shell Samfur

-

OEM Grey Cast Iron Casting

-

Alloy Karfe Guduro Mai Rufaffen Yashi Simintin Wuta Crankshaft

-

Alloy Karfe Sand Castings

-

Garin Motar Motar Alloy ta Sand Casting da CNC...

-

Kamfanin Simintin Karfe Karfe

-

Cast Karfe Sand Casting

-

Aluminum Alloy Sand Casting