Iron simintin ruwan toka na al'adasamfuran simintin gyare-gyaren harsashitare da ayyuka naInjin CNC, zafi magani da surface jiyya.

Ƙarfe mai launin toka, ko baƙin ƙarfe mai launin toka, nau'in ƙarfe ne na simintin ƙarfe wanda ke da ƙananan ƙirar graphite. Ana kiranta da launin toka mai launin toka na karyewar da ya yi. Ana amfani da baƙin ƙarfe mai launin toka don gidaje inda taurin ɓangaren ke da mahimmanci fiye da ƙarfin ƙarfinsa, kamar tubalan ingin konewa na ciki, gidajen famfo, jikin bawul, akwatunan lantarki, ma'aunin nauyi da simintin ado. Babban ƙarfin wutar lantarki na simintin ƙarfe mai launin toka da ƙayyadaddun ƙarfin kai galibi ana amfani da su don yin girkin ƙarfe na simintin ƙarfe da rotors na diski.

Halin sinadari na yau da kullun don samun ƙananan ƙirar hoto shine 2.5 zuwa 4.0% carbon da 1 zuwa 3% silicon ta nauyi. Graphite na iya ɗaukar kashi 6 zuwa 10% na ƙarar baƙin ƙarfe. Silicon yana da mahimmanci don yin baƙin ƙarfe mai launin toka sabanin farin ƙarfe na simintin ƙarfe, saboda silicon wani abu ne mai daidaita graphite a cikin simintin ƙarfe, wanda ke nufin yana taimakawa gami samar da graphite maimakon ƙarfe carbides; a 3% silicon kusan babu carbon da aka gudanar a cikin sinadaran hade da baƙin ƙarfe.

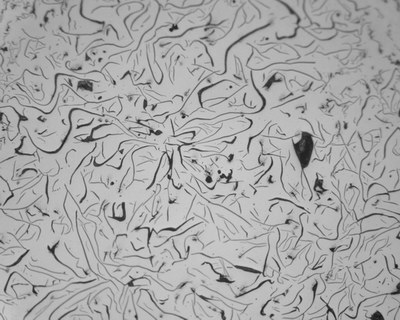

Zane-zanen yana ɗaukar siffar flake mai girma uku. A cikin ma'auni biyu, kamar yadda fuskar da aka goge za ta bayyana a ƙarƙashin na'ura mai ma'ana, flakes na graphite suna bayyana a matsayin layi mai kyau. Tukwici na flakes suna aiki azaman darasi na farko; saboda haka, yana da karye. Kasancewar flakes na graphite yana sa Iron ɗin Grey cikin sauƙin aiki yayin da suke saurin fashewa cikin sauƙi a fadin faifan graphite. Iron baƙin ƙarfe shima yana da kyakkyawan ƙarfin damping don haka galibi ana amfani dashi azaman tushe don hawa kayan aikin injin.

Halayen Injini na Ƙarfin Cast ɗin Grey | |||||||

| Abu bisa ga DIN EN 1561 | Auna | Naúrar | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | EN-JL 1030 | EN-JL 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Ƙarfin Ƙarfin Ƙarfi | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 |

| 0.1% Ƙarfin Haɓaka | Rp0,1 | MPA | 98-165 | 130-195 | 165-228 | 195-260 | 228-285 |

| Ƙarfin Ƙarfi | A | % | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 | 0,3 - 0,8 |

| Ƙarfin Ƙarfi | Ƙaddamarwa dB | MPa | 600 | 720 | 840 | 960 | 1080 |

| 0.1% Ƙarfin Ƙarfi | ku 0,1 | MPa | 195 | 260 | 325 | 390 | 455 |

| Ƙarfin Flexural | Ƙaddamarwa bB | MPa | 250 | 290 | 340 | 390 | 490 |

| Schuifspanning | σaB | MPa | 170 | 230 | 290 | 345 | 400 |

| Danniya mai ƙarfi | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Modules na elasticity | E | GPA | 78-103 | shafi na 88-113 | 103-118 | 108-137 | shafi na 123-143 |

| Lambar guba | v | - | 0,26 | 0,26 | 0,26 | 0,26 | 0,26 |

| Brinell taurin | HB | 160-190 | 180-220 | 190-230 | 200-240 | 210-250 | |

| Halittu | Ƙaddamarwa bW | MPa | 70 | 90 | 120 | 140 | 145 |

| Tashin hankali da canjin matsa lamba | Ƙaddamar da W | MPa | 40 | 50 | 60 | 75 | 85 |

| Ƙarfin Ƙarfi | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Yawan yawa | g/cm3 | 7,10 | 7,15 | 7,20 | 7,25 | 7,30 | |

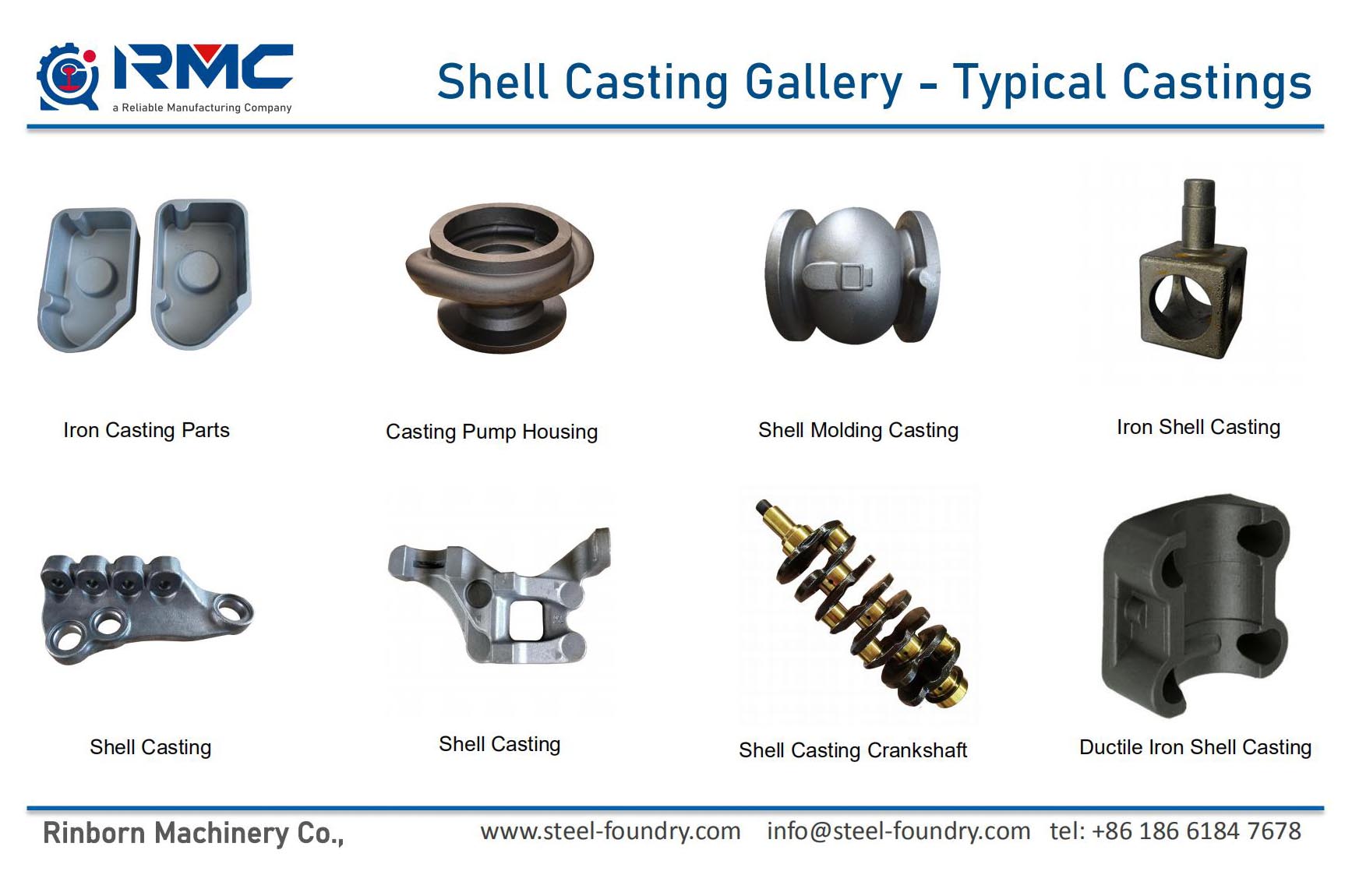

Shell gyare-gyaren simintin gyaran kafatsari kuma ana kiransa tsarin simintin simintin yashi wanda aka riga aka rufawa, simintin gyare-gyaren harsashi mai zafi ko tsarin simintin simintin. Babban kayan gyare-gyaren shine yashin resin phenolic wanda aka riga aka yi masa rufi, wanda yafi tsada fiye da koren yashi da yashin guduro mai fure. Bugu da ƙari, wannan yashi ba za a iya sake yin amfani da shi ba.

Furan resin resin kansa tsarin simintin yashi (tsari na nobake) yana amfani da yashi mai rufi na fure don samar da simintin simintin. Bayan an haxa yashi na asali (ko yashi da aka dawo da shi), ruwa mai buɗe wuta da mai kara kuzari daidai gwargwado, sannan a cika su a cikin ainihin akwatin (ko akwatin yashi), sannan a matsa shi don ya taurare ya zama mold ko gyaggyarawa a cikin babban akwatin (ko yashi). akwatin) a dakin da zafin jiki. Sa'an nan kuma aka samar da simintin gyare-gyare ko simintin simintin, wanda ake kira akwatin gyare-gyaren sanyi mai ƙarfi (core), ko hanyar tauraruwar kai (core).

Saboda ana yin ƙura a cikin ɗaki kuma ba buƙatar zafi ba, ana kiran simintin yashi mai taurin kai kuma ana kiran tsarin simintin gasa. Hanyar taurin kai za a iya raba shi zuwa guduro furan mai acid-catalyzed da phenolic guduro yashi hanya mai taurin kai, hanyar tauraruwar yashi na urethane da kuma hanyar taurin kai mai phenolic monoester.

A matsayin yashi mai ɗaure mai sanyi mai ɗaure kai, yashi farin resin shi ne yashi na farko kuma a halin yanzu ana amfani da yashi mai ɗaure mai ɗaure da yawa a cikin ginin Sinanci. Adadin resin da aka ƙara a cikin yashi gyare-gyare shine gabaɗaya 0.7% zuwa 1.0%, kuma adadin ƙarar guduro a cikin yashi gabaɗaya shine 0.9% zuwa 1.1%. Abubuwan da ke cikin aldehyde kyauta a cikin resin furan bai kai 0.3% ba, kuma wasu masana'antu sun ragu zuwa ƙasa da 0.1%. A cikin wuraren da aka gano a kasar Sin, yashi mai taurin kai ya kai matakin kasa da kasa ba tare da la'akari da yadda ake samar da simintin gyaran fuska ba.

Daidai Makin Ƙarfin Simintin Ruwa na Grey | ||||||||

| AISI | W-tafi | DIN | BS | SS | AFNOR | UNE / IHA | JIS | UNI |

| A48-20B | 0.6010 | GG-10 | Darasi na 100 | 0110-00 | - | - | Farashin FC100 | G 10 |

| A48-25B | 0.6015 | GG-15 | Darasi na 150 | 0115-00 | Ft 15 D | FG 15 | Farashin FC150 | G 15 |

| A48-30B | 0.6020 | GG-20 | Darasi na 200 | 0120-00 | Ft 20 D | FG 20 | FC 200 | G 20 |

| A48-40B | 0.6025 | GG-25 | Darasi na 250 | 0125-00 | Ft 25 D | FG 25 | Farashin FC250 | G 25 |

| A48-45B | 0.6030 | GG-30 | Darasi na 300 | 0130-00 | Ft 30 D | FG 30 | Farashin FC300 | G 30 |

| A48-50B | 0.6035 | GG-35 | Darasi na 350 | 0135-00 | Ft 35 D | FG 35 | Farashin FC350 | G 35 |

| A48-60B | 0.6040 | GG-40 | Darasi na 400 | 0140-00 | Ft 40 D | - | FC 40 | - |

| 32510 | GTS-35 | B340/12 | 0815-00 | MN 35-10 | - | Saukewa: FCMW330 | - | |

| A220-40010 | 0.8145 | GTS-45 | P440/7 | 0852-00 | MN 450 | - | FCMP 440/490 | GMN 45 |

| A220-50005 | 0.8155 | GTS-55-04 | P510/4 | 0854-00 | MP 50-5 | - | Farashin FCMP490 | GMN 55 |

| Saukewa: A220-70003 | 0.8165 | GTS-65-02 | P570/3 | 0856-00 | MN 650-3 | - | Farashin FCMP590 | GMN 65 |

| Saukewa: A220-70003 | - | GTS-65 | P570/3 | 0858 | MN 60-3 | - | Farashin FCMP540 | - |

| Saukewa: A220-80002 | 0.8170 | Saukewa: GTS-70-02 | P690/2 | 0862-00 | MN 700-2 | - | Farashin FCMP690 | GMN 70 |

Ƙarfe Mai Rufaffen Yashi da Ƙarfe da Alloys | |

| Karfe & Alloys | Shahararen daraja |

| Grey Cast Iron | GG10~GG40; GJL-100 ~ GJL-350; |

| Ƙarfin Simintin Ƙarfi (Nodular). | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Iron (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Karfe Karfe | C20, C25, C30, C45 |

| Alloy Karfe | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Bakin Karfe | Bakin Karfe na Ferritic, Bakin Karfe Martensitic, Bakin Karfe Austenitic, Hazo Hardening Bakin Karfe, Duplex Bakin Karfe |

| Aluminum Alloys | ASTM A356, ASTM A413, ASTM A360 |

| Brass / Copper na tushen Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Standard: ASTM, SAE, AISI, GOST, DIN, EN, ISO, da GB | |

Fa'idodin Furan Resin Rufaffen Yashi Mai Taurin Kai:

1) Haɓaka daidaiton girma na simintin gyare-gyare da ƙaƙƙarfan saman.

2) Ƙaƙƙarfan yashi (core) yashi baya buƙatar bushewa, wanda zai iya ceton makamashi, kuma ana iya amfani da katako mai tsada ko akwatunan filastik da samfuri.

3) Yashi mai gyare-gyaren kansa yana da sauƙi don haɗawa da rugujewa, mai sauƙin tsaftace simintin gyare-gyare, kuma ana iya sake yin amfani da tsohon yashi da sake amfani da shi, wanda ke rage yawan ƙarfin aiki na core yin, yin samfuri, yashi fadowa, tsaftacewa da sauran hanyoyin sadarwa, da kuma yana da sauƙin gane injina ko sarrafa kansa.

4) Yawan juzu'i na guduro a cikin yashi shine kawai 0.8% ~ 2.0%, kuma cikakken farashin albarkatun ƙasa yana da ƙasa.

Saboda hanyar taurin kai yana da fa'idodi na musamman da aka ambata a sama, hanyar tauraruwar kai ba wai kawai ana amfani da ita ba ne don yin ginshiƙi, har ma ana amfani da ita don yin gyare-gyare. Ya dace musamman don samar da yanki guda ɗaya da ƙaramin tsari, kuma yana iya samar da baƙin ƙarfe, simintin ƙarfe da simintin ƙarfe mara ƙarfe. Wasu masana'antun kasar Sin sun maye gurbin busassun yashi na yumbu, da yashi na siminti, da wani bangare na maye gurbin yashi na gilashin ruwa.

Kayayyakin Cast ɗin ƙarfe na Musamman