Zuba Jari Cemin Foundry

Yin simintin saka hannun jari, wanda kuma aka sani da simintin kakin zuma da aka ɓace ko kuma daidaitaccen simintin gyare-gyare, tsari ne da aka yi shi tsawon dubban shekaru, tare da ɓataccen tsarin kakin zuma na ɗaya daga cikin tsoffin dabarun samar da ƙarfe.

Saboda hadadden tsari a cikin girma da lissafi, ana samar da simintin saka hannun jari don isa sifar net ko kusa da sifar net, rage buƙatar matakai na biyu kamar lathing, juyawa ko wani abu.Injin CNCtsari.

Simintin saka hannun jari tsari ne na masana'antu wanda za a iya samo shi sama da shekaru 5,000 da suka gabata. Daga wannan lokacin, lokacin da ƙudan zuma ya samar da tsari, zuwa kakin zuma mai girma na fasaha na yau, kayan gyarawa da gami na musamman, ɓataccen simintin kakin zuma yana tabbatar da samar da ingantattun abubuwan haɗin gwiwa tare da fa'idodin daidaito, maimaitawa, da mutunci.

Simintin saka hannun jari ya samo sunansa daga gaskiyar cewa an saka abin ƙira, ko kewaye, tare da wani abu mai karewa. Siffofin kakin zuma suna buƙatar kulawa sosai don ba su da ƙarfi don jure wa sojojin da aka ci karo da su yayin yin gyare-gyare.

Zuba Jari Cemin Foundry

Abin da Za Mu Iya Cimma Ta Hanyar Simintin Zuba Jari Na Lost

Simintin gyare-gyare na kakin zuma da aka rasa tare da silica sol azaman kayan ɗaure na iya isa ƙimar haƙuri mai girma CT4 ~ CT7 bisa ga ISO 8062. Kayan aikin mu cikakke da sarrafa tsarin sarrafa kansa yana ba da damar daidaito da maimaita juzu'i kamar ± 0.1 mm. Theɓatattun sassan simintin kakin zumaHakanan za'a iya samar da su a cikin nau'i mai fadi, suna iya zama ƙanana kamar 10 mm tsayi x 10 mm fadi x 10 mm tsayi kuma suna auna kadan kamar 0.01 kg, ko girma kamar 1000 mm tsayi kuma suna auna kamar 200 kg. .

RMC babban masana'antu ne na masana'antar simintin saka hannun jari mai inganci wanda ya himmatu wajen isar da ingantacciyar inganci, ƙimar ƙima da ƙwarewar abokin ciniki na musamman. RMC yana da gogewa, ƙwararrun fasaha da matakan tabbatar da inganci don a kai a kai da dogaro da isar da ɗimbin simintin gyare-gyare tare da ƙarin aiki.

- • Matsakaicin Girman Simintin Ɗaukaka: 1,000 mm × 800 mm × 800 mm

- • Rage Nauyin Cast: 0.5 kg - 200 kg

- • Ƙarfin shekara:ton 3,000

- Kayayyakin Lantarki don Gina Shell:Silica Sol, Gilashin Ruwa ko gaurayensu.

- • Hakuri da Juriya:CT4 ~ CT7 bisa ga ISO 8062 ko akan Buƙatun.

Yin Shell Lokacin Zuba Jari

Metals da Alloys Za Mu Iya Zuba Ta Zuba Jari

Thezuba jari simintin kafa kafaa RMC yana da ikon saduwa da nau'ikan nau'ikan kayan ƙirar gami da ƙayyadaddun bayanai bisa ga ASTM, SAE, AISI, ACI, DIN, GOST, EN, ISO, da ka'idodin GB. Muna da fiye da 100 nau'ikan ƙarfe daban-daban na ƙarfe da mara ƙarfe waɗanda muke jefa sassa da su ta amfani da tsarin ƙira mai rikitarwa.

- • Ƙarfe mai launin toka:HT150, HT200, HT250, HT300, HT350; EN-GJL-100, EN-GJL-150, EN-GJL-200, EN-GJL-250, EN-GJL-300, EN-GJL-350; GG10, GG15, GG20, GG25, GG30, GG40; ASTM A48 Gray Iron Maki 20, aji 25, aji 30, aji 35, aji 40, aji 45, aji 50, aji 55, aji na 60.

- • Iron Cast (Ƙarfin Nodular):China GB QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2; GGG40, GGG45, GGG50, GGG60, GGG70, GGG80; EN-GJS-400-18, EN-GJS-400-15, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2 GJS-800-2; ASTM A536 Ductile Iron Makin 60-40-18, 65-45-12, 70-50-05, 80-60-03, 100-70-03, 120-90-02.

- •Karfe Karfe:AISI 1020 ~ AISI 1060, C30, C40, C45.

- •Alloy Karfe:ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo, da dai sauransu.

- •Bakin Karfe:AISI 304, AISI 304L, AISI 316, AISI 316L,AISI 347, AISI 430, 1.4401, 1.4404, 1.4408, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571, CF3, CF3M, CF8, CF8M...da sauransu.

- •Duplex Bakin Karfe (DSS)kumaHazo Hardening (PH) Bakin Karfe

- • Brass, Bronze da sauran Alloys na tushen tagulla

- •Nickel Based Alloy (Inconel 625, Inconel 713, Inconel 718 da dai sauransu), Cobalt Based Alloys

- • Karfe mai jure lalata, Karfe mai jure ruwan teku, Karfe mai zafin jiki, Karfe mai tsayi, Bakin Karfe Duplex.

- • Aluminum Alloy A356, A360

- • Sauran Alloys azaman buƙatu ko bisa ga ASTM, SAE, AISI, GOST, DIN, EN, ISO, da GB.

Bakin Karfe Zuba Jari

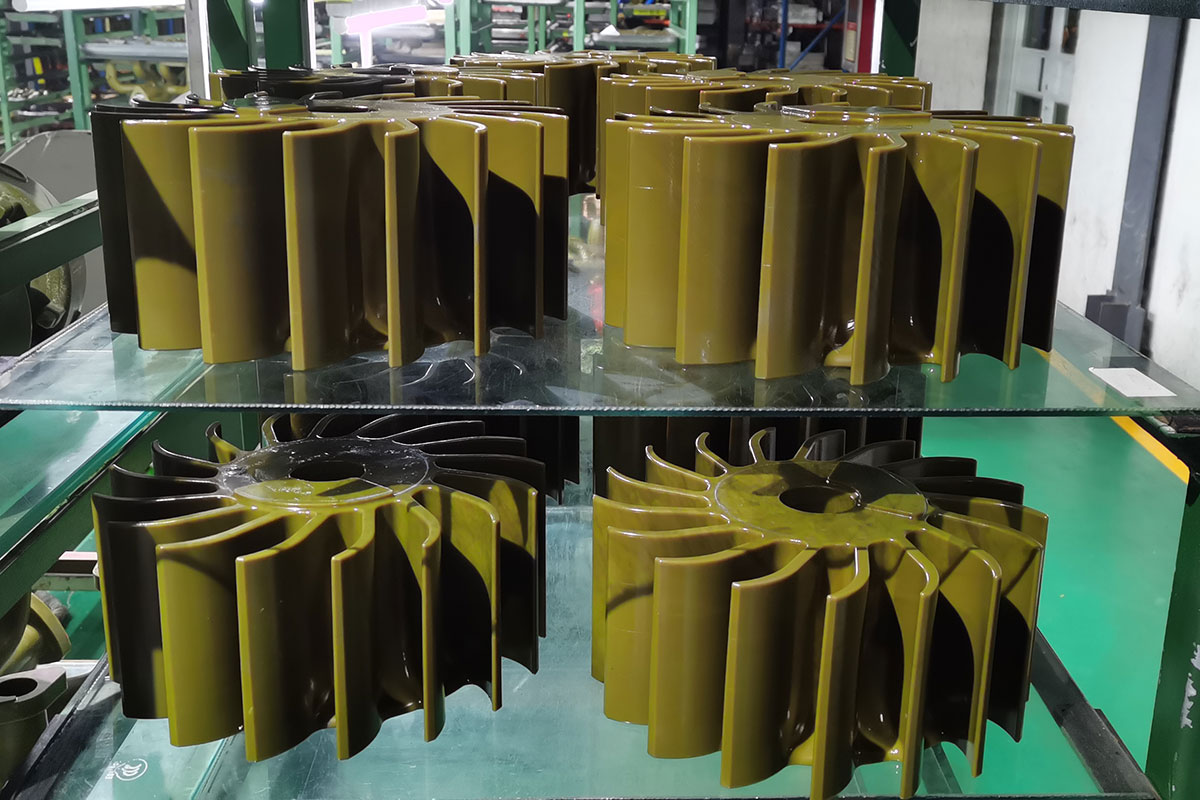

Zuba Jari Simintin gyare-gyare

Al Mold don Rasa Kakin simintin gyaran kafa

Karfe Mold don Zuba Jari

Cikakken Injin Aluminum Alloy Mold don Daidaitaccen Simintin Simintin gyare-gyare

Matakan Simintin Zuba Jari na Kakin Kaki da Batattu

Simintin saka hannun jari tsari ne na matakai da yawa wanda ke samar da siffa ta kusadaidai sassan simintin gyaran kafa. Tsarin yana farawa tare da allurar kakin zuma a cikin mutu don ƙirƙirar ƙirar samfurin da aka gama. Sannan ana manne tsarin a sanduna masu gudu don ƙirƙirar tari.

A lokacin aikin simintin saka hannun jari, na'ura ta musamman tana tsoma gungu akai-akai a cikin slurry don haɓaka harsashi na yumbu, sannan ana cire kakin zuma a cikin injin autoclave. Da zarar an cire kakin zuma, ana harba harsashin yumbu sannan a cika shi da narkakkar karfe don ƙirƙirar sashin. Ɗaya daga cikin fa'idodin zuba jari shine za a iya sake amfani da kakin zuma.

Yin simintin saka hannun jari (Tsarin simintin kakin zuma da aka rasa) yana buƙatar mutuwar ƙarfe (yawanci a cikin aluminium), kakin zuma, yumbu slurry, makera, narkakken ƙarfe, da sauran injinan da ake buƙata don allurar kakin zuma, fashewar yashi, girgizar girgiza, yanke, da niƙa. Tsarin simintin zuba jari ya ƙunshi matakai masu zuwa:

1- Karfe Mutu Making

Dangane da zane-zane da buƙatun ɓangaren simintin da ake so, ƙarfe ya mutu ko ƙura, yawanci a cikin aluminum, za a ƙira da samarwa. Kogon zai samar da girman iri ɗaya da tsarin ɓangaren simintin da ake so.

2- Allurar kakin zuma

Hakanan kamar yadda aka sani da ƙirƙira ƙirar ƙirƙira, ƙirar simintin kakin da aka ɓace ana ƙirƙira ta hanyar allurar narkakken kakin zuma a cikin mutuƙar ƙarfe a sama.

3- Majalisar Slurry

Sa'an nan kuma an haɗa ƙirar kakin zuma zuwa tsarin gating, wanda yawanci tsarin tashoshi ne wanda wani narkakkar ƙarfe ke tafiya zuwa cikin rami. Bayan haka, an kafa tsari kamar bishiya, wanda ya dace da samar da yawa.

4- Ginin Shell

Ana gina simintin simintin saka hannun jari na kwandon harsashi ta hanyar tsomawa cikin wankan yumbu sannan kuma nan da nan an rufe shi da yashi na sau da yawa.

5- De-waxing

Sa'an nan kuma an yanke rami na ciki na daidaitaccen simintin saka hannun jari, wanda ya bar ƙwanƙolin harsashi na yumbu na waje. Ramin sarari iri ɗaya ne da simintin da ake so.

6-Pre-Pouring Analysis

Binciken riga-kafi yana nufin cewa ma'adanin yana buƙatar bincika da kuma nazarin abubuwan da ke tattare da narkakken ƙarfen don ganin ko sun dace da lambobi da ake buƙata ko kuma tauraro. Wasu lokuta, ana yin wannan bincike sau da yawa.

7- Zubawa & Tabbatarwa

Ya kamata a yi zafi harsashi yumbu tare da rami kafin a zuba. Wannan yana hana girgiza da harsashi yumbura yin fashe da zarar an zuba ƙarfen ruwa a cikin matsanancin zafin jiki a cikin rami.

8- Sake Ko Yanke

Da zarar karfen ya huce kuma ya dage, sai a cire sashin simintin (s) daga gunkin tsarin bishiyar ta hanyar girgiza, yanke ko yanke sassa na simintin gyaran kafa.

9- Harbuwa da Harbo da Sarrafa Sakandare

Sa'an nan kuma an daidaita sashin simintin gyare-gyare ta hanyar niƙa ko ƙarin magungunan zafi. Hakanan za'a iya buƙatar injin na biyu ko kuma jiyya na sama dangane da buƙatun ɓangaren.

10-Shiryawa da Bayarwa

Sannan sassan simintin kakin zuma da suka ɓace za a gwada su gaba ɗaya don girma, saman ƙasa, kaddarorin injina da sauran gwaje-gwajen da ake buƙata kafin tattarawa da bayarwa.

Alamomin Kakin Kaki

Bushewar Shell

Kwantar da hankali da ƙarfi

Nika da Tsaftacewa

Yadda Muke Duba Abubuwan Zuba Jari

- • Spectrographic da manual quantitative analysis

- • Binciken Metallographic

- • Gwaje-gwaje masu girma

- • CMM

- • Brinell, Rockwell da Vickers duba taurin

- • Binciken kayan aikin injiniya

- • Gwajin tasiri mara ƙarancin zafi da na al'ada

- • Duban tsafta

- • Binciken UT, MT da RT

- • Ma'auni mai ƙarfi da ƙarfi

- • Gwajin Rufewa da Matsi

Kakin Kwafi

Waɗanne Kamfanonin Muka Dogara Don Yin Simintin Zuba Jari

Toolings Warehouse

Allurar Alamomin Kakin Kaki

Allurar Alamomin Kakin Kaki

Injin allurar kakin zuma

Yin Shell

Yin Shell

Shell Drying Workshop

Shell don Zuba Jari

Bushewar Shell

Shell Shirye don Yin Casting

Kwantar da hankali da ƙarfi

Tsarin Zuba Jari

Waɗanne Masana'antu Kasuwan Jari Namu Ke Bauta

Sassan da aka yi ta hanyar saka jariana amfani da su don jefa abubuwa iri-iri, gami da babban inganci, sassan masana'antu masu girma na sifofi masu rikitarwa.Aikace-aikacen sassan simintin saka hannun jari ya ƙunshi masana'antu da yawa, a cikin kamfaninmu galibi ana amfani da su a wurare masu zuwa:

| •Valve da Pump Parts | • Kayan Aiki |

| • Motoci masu nauyi | • Kayan Aikin Noma |

| • Motoci | •Na'ura mai aiki da karfin ruwa |

| • Kayan Aikin Gina | • Jirgin kasa da kasa |

Aikace-aikace na Zuba Jari

Na al'adaZuba jariMuna samarwa

Za mu iya yin ƙarin ta hanyar Ba da Simintin Zuba Jari da Sauran Sabis:

A RMC, muna alfahari da kanmu wajen baiwa abokan cinikinmu sabis daga ƙirar patter zuwagama simintin gyaran kafada matakai na biyu. Ayyukanmu sun haɗa da:

- - Ƙirar Ƙirar Ƙira da Ƙimar Ƙarfafa Shawarwari.

- - Haɓaka Samfura.

- - Samfuran Bincike da Ci gaba.

- - Samfuran Samfura.

- - Cancanta da Gwaji.

- - Ana samun Maganin zafi da Jiyya na Sama.

- - Ƙarfin Ƙarfafa Ƙarfafawa

Bakin Karfe Zuba Jari

Me yasa kuka Zaɓi RMC don Samar da Simintin Zuba Jari

Akwai dalilai da yawa don zaɓar RMC azaman tushen ku don simintin saka hannun jari. Lokacin da kuka yanke shawara, kuna iya damu da abubuwan da ke gaba waɗanda muke da kyau a hidima:

- - Tawagar injiniyoyi waɗanda membobinta ke mai da hankali kan filin simintin ƙarfe.

- - Experiencewarewa mai zurfi tare da sassan geometries masu rikitarwa

- - Kayayyaki masu yawa, gami da na'urorin ƙarfe da na ƙarfe waɗanda ba na ƙarfe ba

- - A cikin gidaInjin CNCiyawa

- - Maganganun tsayawa ɗaya don simintin saka hannun jari da tsari na biyu

- - Tabbatar da ingancin inganci da ci gaba da ci gaba.

- - Haɗin kai wanda ya haɗa da masu samar da kayan aiki, injiniyoyi, mai kafa, injiniyoyi da ƙwararrun samarwa.