Dukansu baƙin ƙarfe mai launin toka da baƙin ƙarfe za a iya jefa sutsarin simintin yashi, Tsarin simintin gyare-gyaren harsashi (Yashi mai rufi na guduro), ɓataccen simintin kumfa, zubar da ruwa da simintin saka hannun jari. Yashi simintin gyare-gyare yana ɗaya daga cikin shahararrun kuma mafi sauƙi nau'ikan yin simintin. Yin simintin yashi yana ba da damar ƙananan batches fiye da simintin gyare-gyare na dindindin kuma a farashi mai ma'ana. Ba wai kawai wannan hanyar ta ba wa masana'anta damar ƙirƙirar kayayyaki a farashi mai rahusa ba, amma akwai wasu fa'idodi ga simintin yashi, kamar ayyuka masu ƙanƙanta. Yin simintin yashi kuma yana ba da damar jefa yawancin karafa, ya danganta da irin yashi da ake amfani da su don gyare-gyaren. Tsarin simintin gyare-gyaren harsashi kuma ana kiransa tsarin simintin simintin gyare-gyaren yashi wanda aka riga aka rufa, da simintin gyare-gyaren harsashi mai zafi ko ainihin aiwatar da simintin simintin. Babban kayan gyare-gyaren shine yashin resin phenolic wanda aka riga aka yi masa rufi, wanda yafi tsada fiye da koren yashi da yashin guduro mai fure. Bugu da ƙari, wannan yashi ba za a iya sake yin amfani da shi ba. Sassan gyare-gyaren ƙarfe na harsashi suna da tsada fiye da simintin yashi. Duk da haka, dasassan simintin gyare-gyaren harsashisuna da fa'idodi da yawa kamar juriyar juriya mai ƙarfi, ingantaccen ingancin ƙasa da ƙarancin lahani.

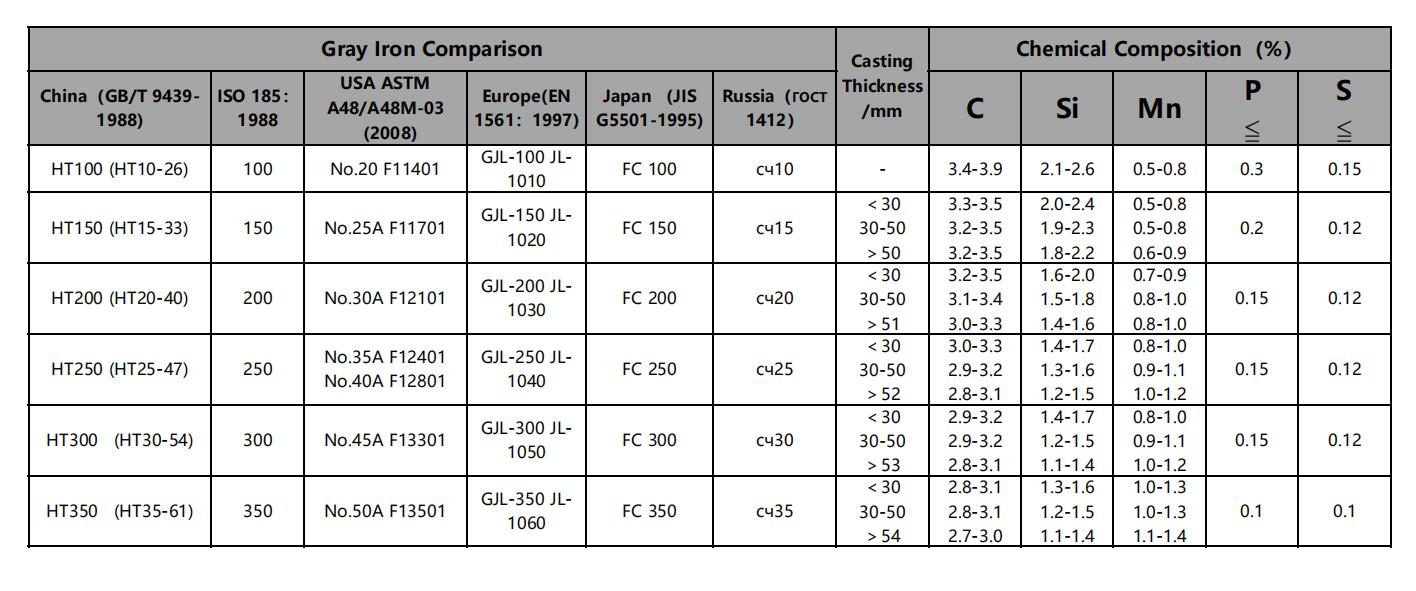

Koyaya, har yanzu akwai wasu bambance-bambance tsakanin sassan simintin ƙarfe mai launin toka da sassan simintin ƙarfe.Grey Iron Sand Castinggalibi ana amfani da shi don yin hadaddun sifofi waɗanda zasu zama masu wahala ko rashin tattalin arziki don yin ta wasu hanyoyin samar da ƙarfe. Godiya ga sauƙi na mashin ɗin, ƙarfin matsawa mai ƙarfi, mafi kyawun yanayin zafi da ingantaccen ɗaukar girgiza, baƙin ƙarfe mai launin toka yana ɗaya daga cikin ƙarfen simintin da aka fi amfani da shi na dogon lokaci, har ma a cikin samar da masana'antu na yanzu. Abubuwan da ke cikin Carbon ya kasance mafi mahimmanci ga ƙarfe mai launin toka (yawanci 2% zuwa 4%) don ƙirƙirar ƙarfin ƙarfi da injina. Lokacin da narkakken simintin ƙarfe yana ƙarfafa wasu daga cikin carbon da ke hazo a matsayin graphite, suna yin ƙanƙanta, flakes marasa tsari a cikin tsarin kristal na ƙarfe wanda ke haɓaka kyawawan kaddarorin simintin ƙarfe, flakes ɗin suna rushe tsarin crystal wanda ke haifar da sifar sifa ta ƙarfe.

Ƙarfin simintin gyare-gyare na ƙarfe mai launin toka yana haifar da babban ƙarfi. A baya, babbar hanyar inganta aikin ƙarfen simintin launin toka shine allura. A cikin 'yan shekarun nan, babban hanyar da ake bi a yanzu ita ce mayar da hankali kan hadawa, kuma don inganta aikin simintin gyare-gyare, yawancin masana'antun ƙarfe masu launin toka suna amfani da simintin ƙarfe tare da mafi girman carbon daidai. Wannan yana da mahimmanci musamman ga ƙananan simintin ƙarfe. Sabili da haka, baƙin ƙarfe mai launin toka ya dace da kayan da za a samar da sassan simintin ƙarfe na toshe injin, gidaje na injina, tushe na injin, ma'aunin nauyi, sassan murhu, sassan tukunyar jirgi, harsashi na famfo da sauransu.

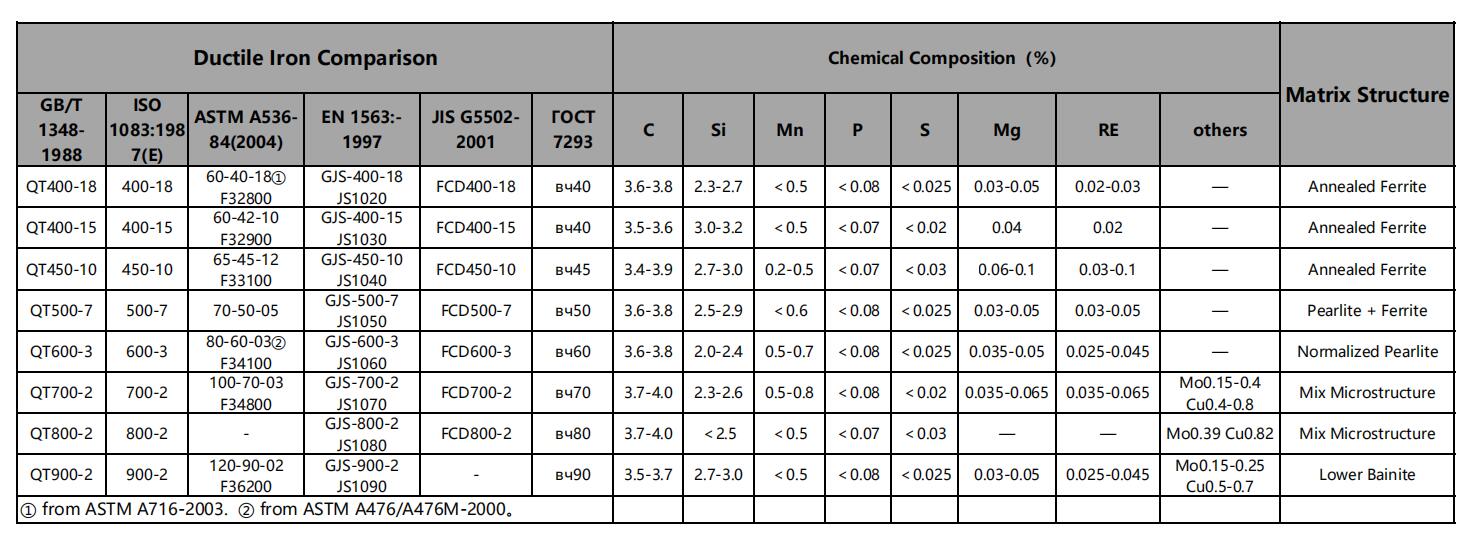

Iron Ductile yana ba da sassaucin ƙira da rage farashin masana'anta tare da ƙirƙira walda da ƙirƙira. A cikin microstructure na ductile baƙin ƙarfe, graphite forms zuwa mai siffar zobe nodules maimakon flakes, don haka inhibiting halittar fasa da samar da ingantattun ductility cewa ya ba gami da sunansa. Ƙarfin ƙwanƙwasa yana da ƙarfi mafi girma da tauri kama da ƙarfe.Simintin gyaran ƙarfesuna da halaye da yawa, duk da haka, ba koyaushe ba ne mafi tsada-tsari madadin sauran ferrous gami. Bugu da ƙari, ana amfani da ƙarfe na ductile a cikin masana'antun masana'antu da yawa, ciki har da aikin gona, kera motoci, injinan ruwa, jiragen ƙasa, manyan motocin kasuwanci da masana'antar sararin samaniya.

Lokacin aikawa: Janairu-27-2021