Ƙarfe mai jurewa (ko juriya) simintin simintin gyare-gyaren ƙarfe yana nufin simintin ƙarfe mai juriya mai kyau. Dangane da abun da ke tattare da sinadarai, an raba shi zuwa simintin simintin gyare-gyaren da ba a haɗa shi ba, ƙananan gawa da ƙarancin gami da juriya. Akwai da yawa iri na lalacewa-resistant karfe, wanda za a iya wajen zuwa kashi high-manganese karfe, matsakaici da kuma low-alloy lalacewa-resistant karfe, chromium-molybdenum-silicon-manganese karfe, cavitation-resistant karfe, sa-resistant karfe, da karfe na musamman mai jurewa. Hakanan ana amfani da wasu karafa na gabaɗaya irin su bakin karfe, ƙarfe mai ɗaukar nauyi, ƙarfe kayan aiki na gami da tsarin ƙarfe na alloy azaman ƙarfe mai jure lalacewa ƙarƙashin takamaiman yanayi.

Matsakaici da ƙananan ƙarfe masu jure lalacewa yawanci suna ɗauke da sinadarai irin su silicon, manganese, chromium, molybdenum, vanadium, tungsten, nickel, titanium, boron, jan ƙarfe, ƙasa da ba kasafai, da dai sauransu. The liners na yawa manya da matsakaici-sized ball. ana yin niƙa a Amurka da chromium-molybdenum-silico-manganese ko chromium-molybdenum karfe. Yawancin ƙwallayen niƙa a Amurka an yi su ne da matsakaici da babban ƙarfe na chromium molybdenum na carbon. Don kayan aikin da ke aiki a ƙarƙashin ingantacciyar yanayin zafi (alal misali, 200 ~ 500 ℃) yanayin lalacewa ko kuma waɗanda saman su ke fuskantar matsanancin yanayin zafi saboda tsananin zafi, gami da chromium molybdenum vanadium, chromium molybdenum vanadium nickel ko chromium molybdenum vanadium tung tung. za a iya amfani da.

Abrasion wani lamari ne wanda kayan da ke saman aiki na abu ke ci gaba da lalacewa ko ɓacewa cikin motsin dangi. Rarrabu ta hanyar lalacewa, ana iya raba lalacewa zuwa lalacewa mai lalacewa, lalacewa mai mannewa, lalatawar lalacewa, lalacewa na lalacewa, lalacewa ta jiki, lalacewa mai tasiri, lalacewa mai ban tsoro da sauran nau'ikan. A cikin masana'antu filin, abrasive lalacewa da m lalacewa lissafin ga mafi girma rabo na workpiece lalacewa kasawa, da kuma sa gazawar halaye kamar yashwa, lalata, gajiya, da fretting ayan faruwa a cikin aiki na wasu muhimman sassa, don haka suna samun ƙarin. da karin hankali. A ƙarƙashin yanayin aiki, nau'ikan lalacewa da yawa sau da yawa suna bayyana a lokaci ɗaya ko ɗaya bayan ɗaya, kuma hulɗar lalacewa yana ɗaukar nau'i mai rikitarwa. Ƙayyade nau'in gazawar lalacewa na aikin aikin shine tushen ingantaccen zaɓi ko haɓaka ƙarfe mai jure lalacewa.

Bugu da ƙari, lalacewa na sassa da kayan aiki matsala ce ta injiniyan tsarin. Akwai dalilai da yawa waɗanda ke shafar lalacewa, ciki har da yanayin aiki (nauyi, saurin motsi, yanayin motsi), yanayin lubrication, abubuwan muhalli (danshi, zafin jiki, kafofin watsa labarai da ke kewaye, da sauransu), da abubuwan abubuwa (Haɗin, ƙungiya, kaddarorin inji), farfajiya. inganci da jiki da sinadarai Properties na sassa. Canje-canje a cikin kowane ɗayan waɗannan abubuwan na iya canza adadin lalacewa har ma da canza tsarin lalacewa. Ana iya ganin cewa kayan abu ɗaya ne kawai daga cikin abubuwan da suka shafi lalacewa na kayan aiki. Don inganta juriya na juriya na sassa na ƙarfe, ya zama dole don farawa tare da juzu'in juzu'i da tsarin lalacewa a ƙarƙashin takamaiman yanayi don cimma tasirin da ake so.

1. Magani Zafin Magani (Maganin Ƙarfin Ruwa) na Simintin Ƙarfe Mai Juriya Mai Girman Manganese

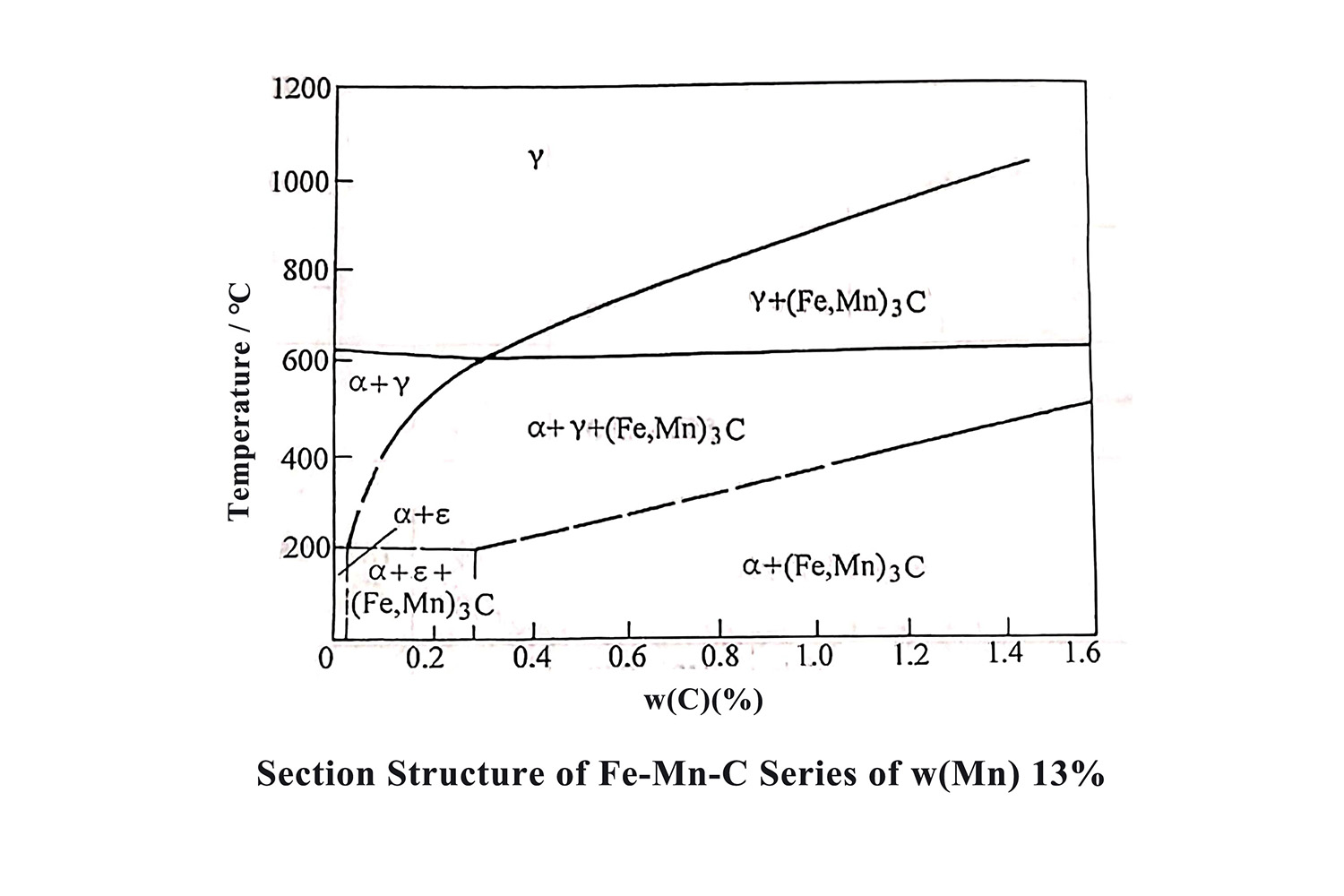

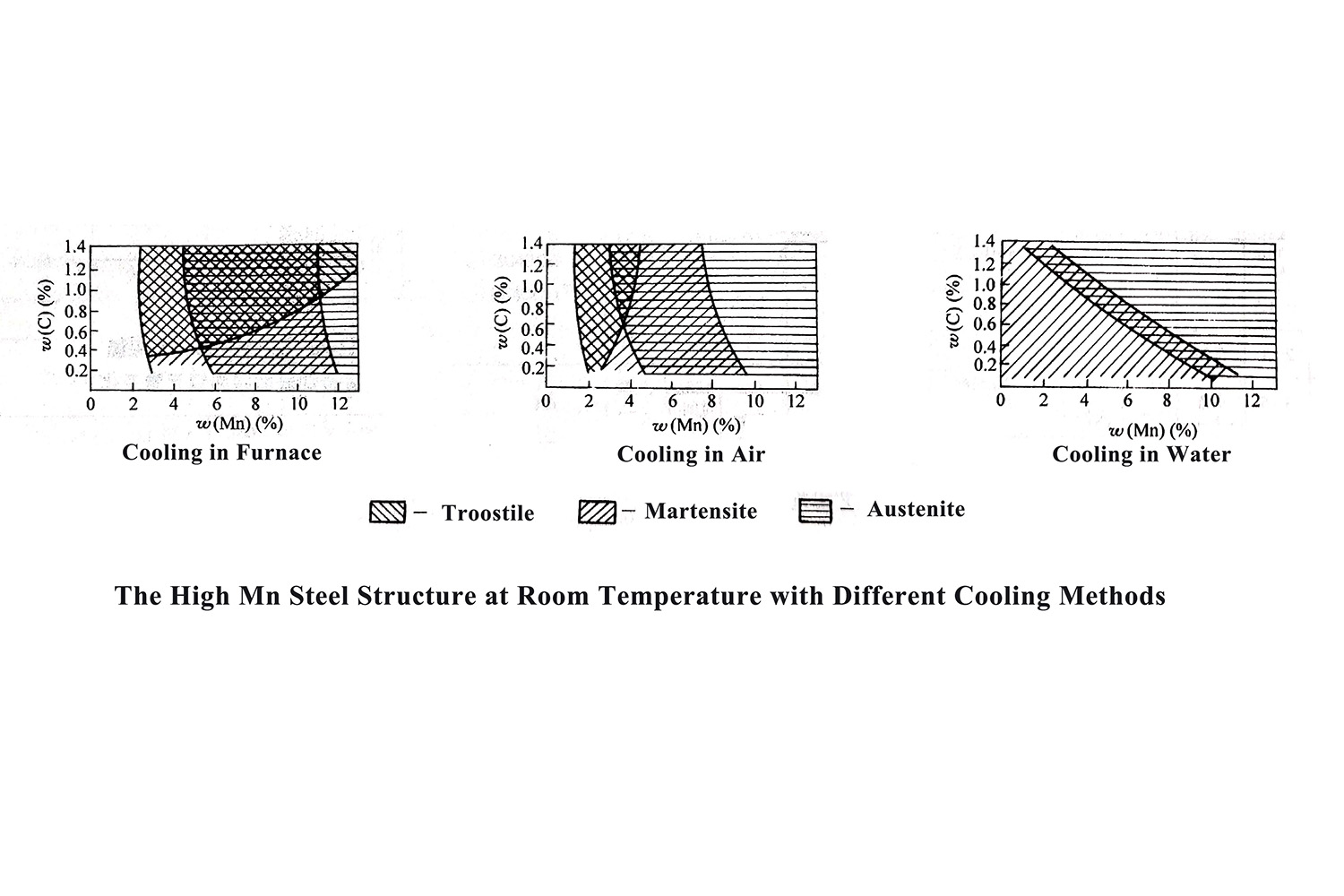

Akwai adadi mai yawa na carbides da aka haɗe a cikin tsarin simintin simintin gyare-gyare na ƙarfe mai ƙarfi-manganese mai jure lalacewa. Wadannan carbides za su rage taurin simintin gyare-gyare kuma su sauƙaƙa karaya yayin amfani. Babban manufar maganin zafi mai zafi na babban simintin ƙarfe na manganese shine don kawar da carbides a cikin tsarin simintin simintin gyare-gyare da kuma kan iyakokin hatsi don samun tsarin austenite na lokaci-lokaci. Wannan zai iya inganta ƙarfi da taurin babban ƙarfe na manganese, don haka babban simintin ƙarfe na manganese ya dace da filayen filayen.

Maganin zafi na maganin simintin ƙarfe mai ƙarfi-manganese mai jurewa za a iya kasu kusan zuwa matakai da yawa: dumama simintin zuwa sama da 1040 ° C da riƙe su don lokacin da ya dace, ta yadda carbides a ciki suna narkar da su gaba ɗaya austenite lokaci-lokaci. ; sa'an nan sauri sanyaya , Get austenite m tsarin bayani. Wannan maganin maganin ana kuma kiransa maganin taurin ruwa.

(1) Zazzabi na maganin taurin ruwa

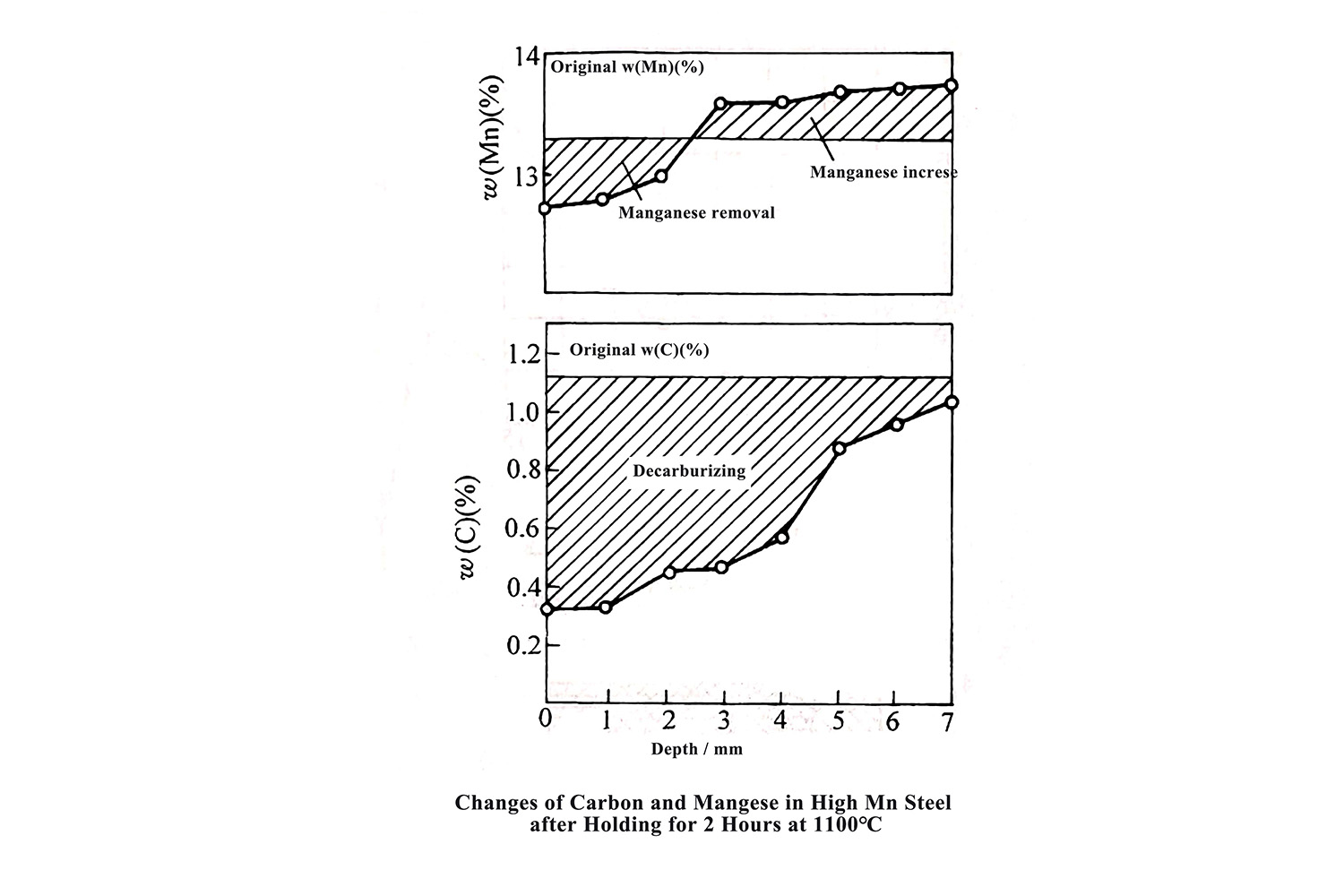

Ruwa taurin zafin jiki ya dogara da sinadaran abun da ke ciki na babban manganese karfe, yawanci 1050 ℃-1100 ℃. Manyan ƙarfe na manganese tare da babban abun ciki na carbon ko babban abun ciki na gami (kamar ZG120Mn13Cr2 karfe da karfe ZG120Mn17) yakamata su ɗauki iyakar zafin zafin ruwa. Duk da haka, yawan zafin jiki mai tsanani na ruwa zai haifar da mummunan lalacewa a saman simintin gyare-gyaren da kuma saurin girma na babban hatsin ƙarfe na manganese, wanda zai shafi aikin babban ƙarfe na manganese.

(2) Yawan dumama maganin taurin ruwa

Thermal watsin karfe manganese ne mafi muni fiye da na janar carbon karfe. Babban simintin ƙarfe na manganese yana da babban damuwa kuma yana da sauƙin fashe lokacin zafi, don haka ƙimar dumama ya kamata a ƙayyade gwargwadon kaurin bango da siffar simintin. Gabaɗaya magana, simintin gyare-gyare tare da ƙaramin kauri na bango da tsari mai sauƙi ana iya yin zafi da sauri; ya kamata a yi zafi da simintin gyare-gyare tare da kaurin bango mafi girma da kuma hadadden tsari. A cikin ainihin tsarin maganin zafi, don rage lalacewa ko fashewar simintin gyare-gyare a lokacin aikin dumama, ana yin zafi sosai zuwa kusan 650 ℃ don kiyaye bambancin zafin jiki tsakanin ciki da waje na simintin ya ragu, kuma zafin jiki a ciki. tanderun ne uniform, sa'an nan da sauri tashi zuwa ruwa taurin zafin jiki.

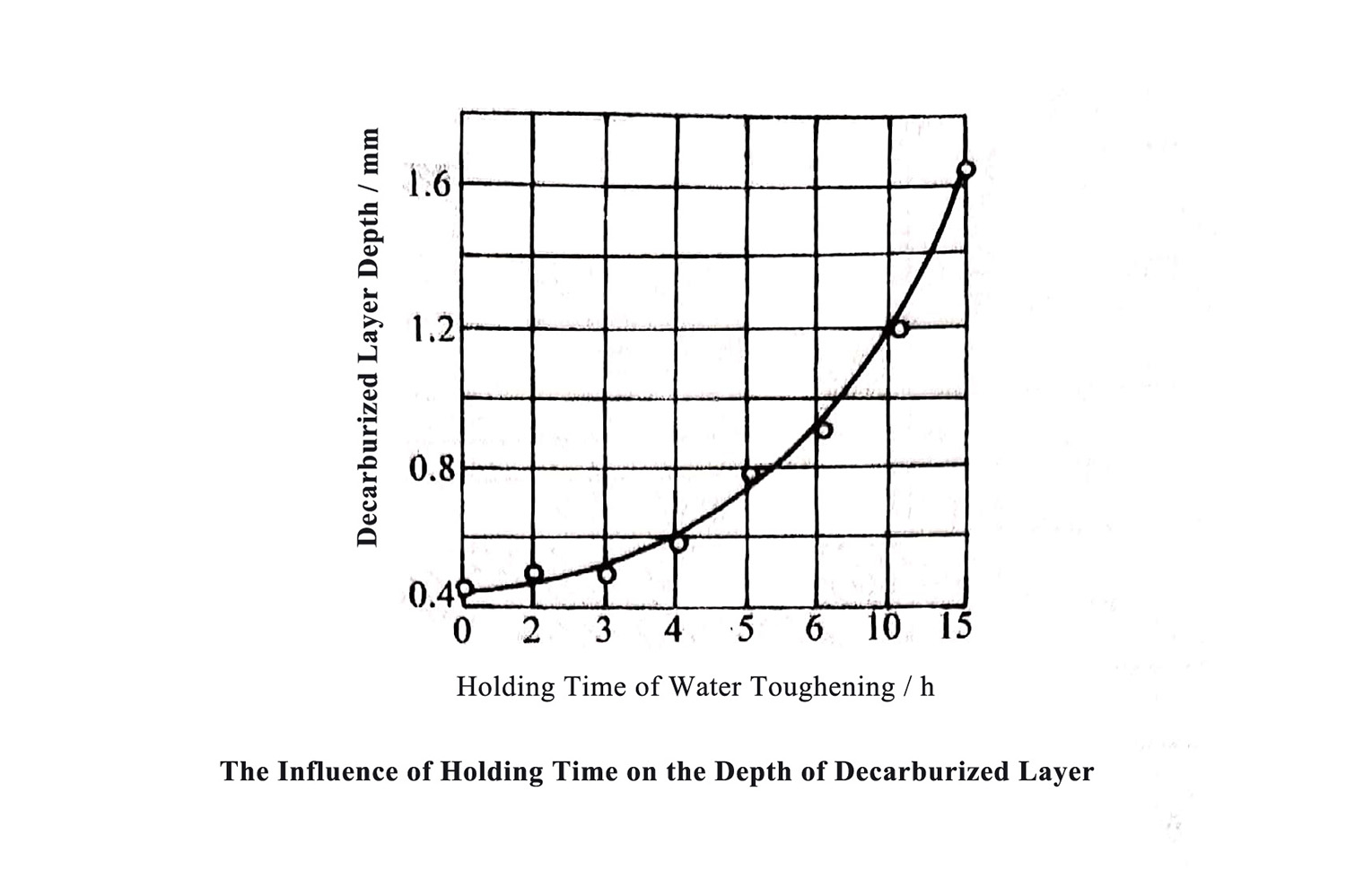

(3) Rike lokacin maganin taurin ruwa

Rike lokacin da ruwa toughening jiyya yafi dogara a kan bango kauri na simintin gyaran kafa, domin tabbatar da cikakken rushe carbides a cikin as-simintin tsarin da homogenization na austenite tsarin. A ƙarƙashin yanayi na al'ada, ana iya ƙididdige shi ta hanyar ƙara lokacin riƙewa da sa'a 1 don kowane haɓakar mm 25 na kauri na bango.

(4) Sanyaya maganin taurin ruwa

Tsarin sanyaya yana da babban tasiri akan ma'aunin aikin da tsarin simintin. Yayin maganin taurin ruwa, zafin simintin gyaran kafa kafin shigar da ruwa ya kamata ya kasance sama da 950 ° C don hana karbides sake hazo. Don haka, tazarar lokaci tsakanin fitar da wuta da shiga cikin ruwa bai kamata ya wuce daƙiƙa 30 ba. Ruwan zafin jiki ya kamata ya kasance ƙasa da 30 ° C kafin simintin ya shiga cikin ruwa, kuma iyakar zafin ruwa bayan shigar da ruwa kada ya wuce 50 ° C.

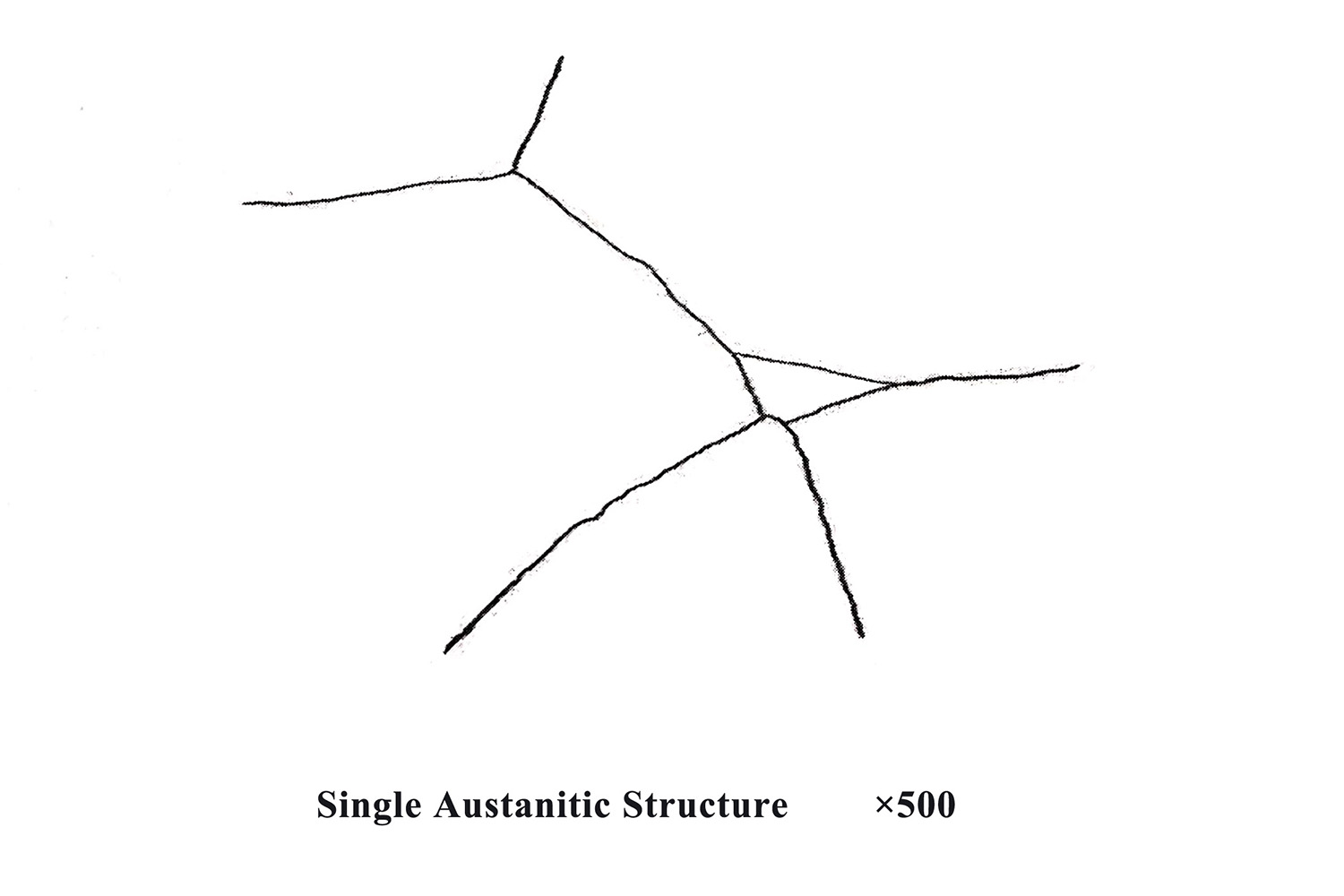

(5) Carbide bayan maganin taurin ruwa

Bayan maganin toughing na ruwa, idan an kawar da carbides a cikin babban ƙarfe na manganese gaba ɗaya, tsarin metallographic da aka samu a wannan lokacin shine tsarin austenite guda ɗaya. Amma irin wannan tsarin za a iya samu ne kawai a cikin simintin gyare-gyaren bango. Gabaɗaya, ana ba da izinin ƙaramin adadin carbide a cikin hatsi na Austenite ko akan iyakokin hatsi. Carbides da ba a narkar da su ba kuma ana iya kawar da su ta hanyar maganin zafi kuma. Koyaya, eutectic carbides da ke haɗewa saboda yawan zafin jiki mai zafi yayin jiyya mai ƙarfi na ruwa ba a yarda da su ba. Domin ba za a iya kawar da eutectic carbide ta hanyar maganin zafi ba kuma.

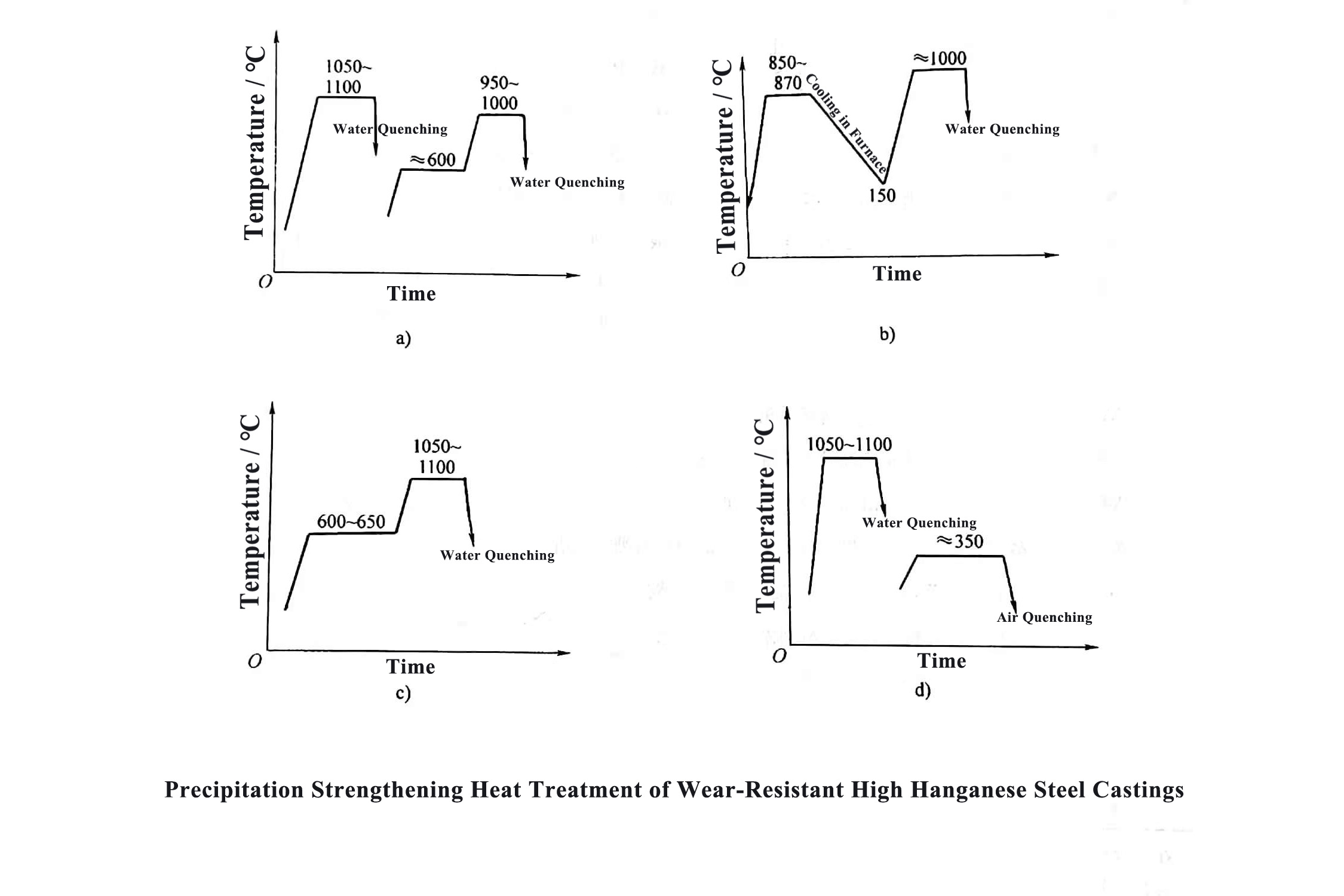

2. Hazo Yana Ƙarfafa Zafin Maganin Sawa Mai Jurewa Babban Hanganese Karfe

Hazo-ƙarfafa zafin zafi na ƙarfe mai jure lalacewa na manganese yana nufin ƙarin adadin adadin abubuwan da ke samar da carbide (kamar molybdenum, tungsten, vanadium, titanium, niobium da chromium) ta hanyar maganin zafi don samun takamaiman adadi da girman a ciki. high manganese karfe Kashi na biyu na tarwatsa carbide barbashi. Wannan maganin zafi zai iya ƙarfafa matrix austenite kuma ya inganta juriya na babban ƙarfe na manganese.

3. Maganin Zafi na Matsakaicin Ƙarfe Chromium Mai jurewa

Manufar maganin zafi na simintin simintin gyare-gyare na matsakaici na chromium mai jurewa shine don samun tsarin matrix na martensite tare da babban ƙarfi, ƙarfi da tauri mai ƙarfi, don haɓaka ƙarfi, ƙarfi da juriya na simintin ƙarfe.

Matsakaicin ƙarfe na chromium mai jurewa sawa ya ƙunshi ƙarin abubuwan chromium kuma yana da ƙarfi mafi girma. Saboda haka, da saba zafi magani Hanyar ne: bayan 950 ℃-1000 ℃, ta austenitization, sa'an nan quenching jiyya, da kuma dace tempering magani (yawanci a 200-300 ℃).

4. Maganin Zafi na Simintin Ƙarfe-Ƙaramar Ƙarfe

Ana kula da simintin simintin gyare-gyaren ƙananan ƙarfe mai ƙarfi ta hanyar kashewa a cikin ruwa, kashe mai da kashe iska dangane da abubuwan gami da abun cikin carbon. Ƙarfe mai jure lalacewa ta lu'u-lu'u yana ɗaukar daidaita yanayin zafi + yanayin zafi.

Domin samun matrix martensite tare da babban ƙarfi, tauri da tauri, da kuma inganta juriya na simintin ƙarfe, simintin ƙarfe mara ƙarfi mai jurewa yawanci ana kashe shi a 850-950 ° C kuma yana da zafi a 200-300 ° C. .

Lokacin aikawa: Agusta-07-2021