China OEM al'ada bakin karfe simintin kayayyakin da yashi mold simintin aiwatar da CNC machining.

Yin simintin yashi yana amfani da koren yashi (yashi mai laushi) ko busasshiyar yashi don samar da tsarin gyare-gyare. Thekore yashi simintin gyare-gyareshine mafi dadewa tsarin simintin gyare-gyare da aka yi amfani da shi a tarihi. Lokacin yin gyare-gyaren, ya kamata a samar da tsarin da aka yi da itace ko karfe don samar da rami mara kyau. Karfe da aka narkar da shi sai a zuba a cikin rami don samar da simintin gyare-gyare bayan sanyaya da ƙarfafawa. Yashi simintin gyare-gyare ba shi da tsada fiye da sauran hanyoyin yin simintin gyare-gyare duka don haɓaka ƙirar ƙira da ɓangaren simintin ɓangarorin. Yin simintin yashi, ko da yaushe yana nufin simintin yashi koren (idan babu bayanin musamman). Koyaya, a zamanin yau, sauran hanyoyin yin simintin suma suna amfani da yashi don yin ƙirar. Suna da nasu sunayen, kamarharsashi mold simintin gyaran kafa, farin guduro mai rufi yashi simintin gyaran kafa (babu irin gasa),rasa kumfada vacuum simintin.

Muna da nau'ikan simintin gyare-gyare daban-daban don zaɓinku. Wani ɓangare na tsarin zaɓi don aikinku shine zaɓin tsarin simintin da zai dace da bukatun ku. Mafi shaharar nau'i shine simintin yashi wanda ya haɗa da yin kwafi na gama-gari (ko tsari) wanda aka matse shi da yashi da ƙari don siffata simintin ƙarshe. Ana cire tsarin bayan an yi gyare-gyare ko ra'ayi, kuma an gabatar da karfe ta hanyar tsarin gudu don cika rami. An raba yashi da karfe kuma an tsaftace simintin gyare-gyare kuma an gama don jigilar kaya ga abokin ciniki.

Sand Casting VS Zuba Jari:

Waɗannan matakai biyu na simintin gyare-gyare sun bambanta a cikin kayan gyare-gyaren da ake amfani da su don yin alamu. Yin simintin saka hannun jari yana amfani da kakin zuma don samar da kwafin kakin zuma (shi yasa ake kiranta da simintin kakin simintin gyare-gyare) waɗanda suke da girma da girma iri ɗaya da simintin da ake so. Sa'an nan za a shafe kwafin kakin zuma da yashi da kayan ɗaure (yawanci silica sol ko gilashin ruwa) don gina harsashi mai ƙarfi don zubowar ƙarfe. Yayin da, yashin yashin yakan ɗauki yashi koren yashi ko busassun yashi don yin rami mara zurfi, waɗanda suke da girman da girma iri ɗaya da sassan simintin da ake so. Don duka aikin simintin yashi da tsarin zuba jari, ana iya sake amfani da yashi da kakin zuma. Simintin saka hannun jari yawanci suna da mafi kyawun filaye, daidaiton geometric da girma fiye da simintin yashi.

Hakurin yin simintin ya kasu kashi-kashi Juyin Juriya na Casting (DCT) da Hakuri na Casting Geometric (GCT). Cibiyar mu tana son yin magana da ku idan kuna da buƙatu ta musamman akan abubuwan da ake buƙata. Anan a cikin waɗannan sune jimlar juzu'i na gabaɗaya da za mu iya kaiwa ta hanyar simintin yashi koren, simintin gyare-gyaren harsashi da simintin yashi mai gasa bake ba:

✔ DCT Grade ta Green Sand Casting: CTG10 ~ CTG13

✔ Matsayin DCT ta Shell Mold Casting ko Furan Resin Sand Casting: CTG8 ~ CTG12

✔ GCT Grade ta Green Sand Casting: CTG6 ~ CTG8

✔ GCT Grade ta Shell Mold Casting ko Furan Resin Sand Casting: CTG4 ~ CTG7

Fa'idodin Tsarin Cast Yashi

1- Low Cost saboda arha da kayan gyare-gyaren gyare-gyare da kayan aiki masu sauƙi.

2- Faɗin nauyin naúrar daga 0.10 kg zuwa 500 kgs ko ma mafi girma.

3- Daban-daban Tsari daga nau'i mai sauƙi zuwa nau'i mai rikitarwa.

4- Dace da samar da bukatun na daban-daban yawa.

| Kayayyaki don Tsarin Casting Yashi a Gidan Kafa na RMC | |||

| Kashi | Babban darajar China | darajar Amurka | Jamus Grade |

| Bakin Karfe na Ferritic | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Bakin Karfe | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic bakin karfe | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4404, 80. 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, |

| Hazo Hardening Bakin Karfe | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Bakin Karfe | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

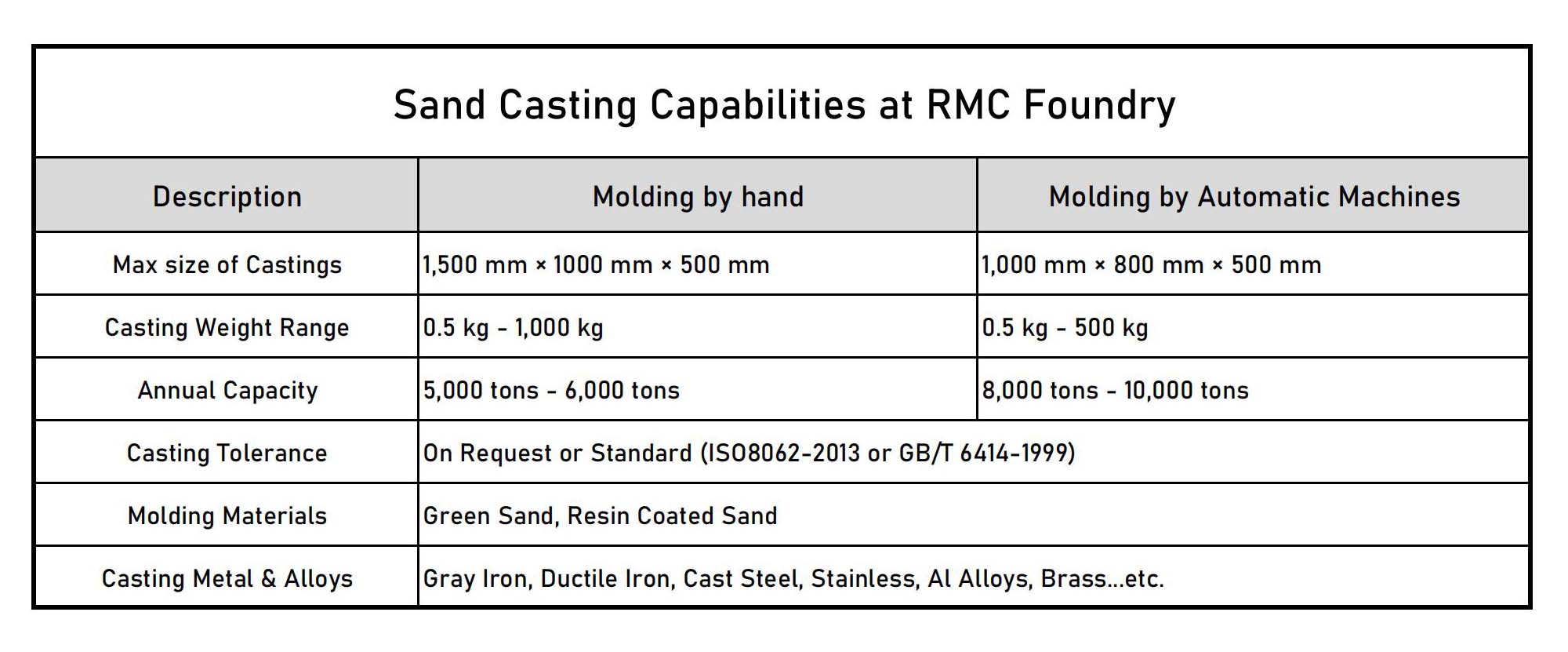

Yashi Molding Foundry